Angle-controllable manual angle folding device for metal plate machining and construction technology

A metal plate and bending device technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult quality control of lock and snap connection, complex plate processing technology, and difficulty in laying out and positioning, and achieve an improvement The effect of improving the appearance quality, locking connection quality, and improving processing and construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

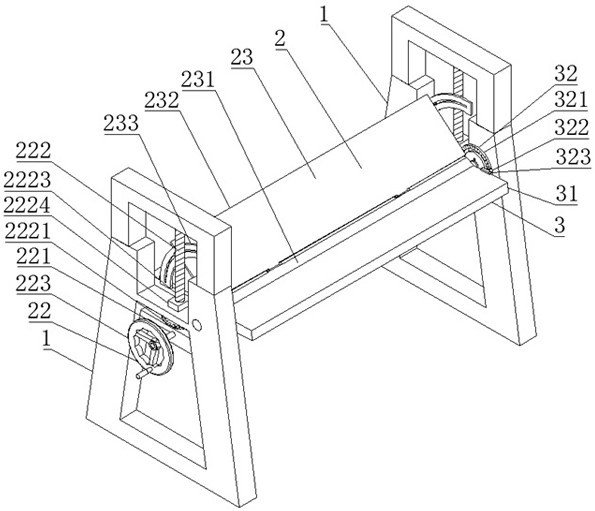

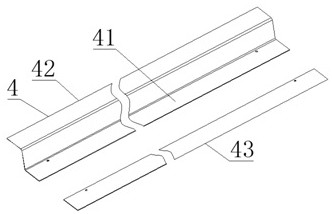

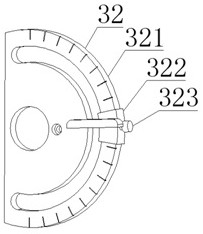

[0057] This embodiment discloses a manual knuckle device for processing sheet metal with controllable angle, refer to figure 1 with figure 2 , including frame 1, clamping device 2, bending device 3 and distance controller 4; clamping device 2 is arranged on frame 1 for loosening and clamping plate 5; bending device 3 includes and frame 1 Rotationally connected turning plate 31 and an angle control instrument panel 32 that limits the turning angle of the turning plate 31; the rotation axis of the turning plate 31 is parallel to the intersection line between the clamping device 2 and the clamped plate 5, and There is a distance to accommodate the thickness of the plate 5 between the axis of rotation and the transition line; the distance controller 4 includes a positioning part 41 configured to be placed on the bent plate 5 when the plate 5 is bent between the two forming surfaces of the plate 5 to control the distance between the two forming surfaces after the plate 5 is bent....

Embodiment 2

[0071] The difference between this embodiment and embodiment 1 is that, as Figure 10 As shown, the pressing mechanism 23 is a hollow triangular prism, and the angle of the pressing mechanism 23 near the turning plate 31 is less than 30 degrees.

[0072] Based on the construction technology of a controllable-angle metal plate processing manual knuckle device disclosed in Embodiment 2, the difference from Embodiment 1 lies in:

[0073] Step 1: Clamp the plate 5 with the clamping device 2;

[0074] Rotate the hand wheel 223, under the action of the moving mechanism 22, lift the pressing mechanism 23, put the plate 5 in, reverse the hand wheel 223 again, drop the pressing mechanism 23 and press the plate 5.

Embodiment 3

[0076] The difference between this embodiment and embodiment 1 is that, as Figure 11 As shown, the distance controller 4 also includes a backing plate 43, and there are two backing plates 43, and the two backing plates 43 are installed on the positioning part 41 by screws to adjust the thickness of the positioning part 41 of the distance controller 4 .

[0077] Based on the construction technology of a controllable-angle metal plate processing manual knuckle device disclosed in Embodiment 3, the difference from Embodiment 1 lies in:

[0078] Step 5: Take out the spacing controller 4, install two backing plates 43 on the positioning part 41, and then place the positioning part 41 in the corner folded in step 4, between the two forming surfaces of the bent plate 5.

[0079] Like this, just can obtain the plate material 5 finished products of two backing plates 43 thicker than embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com