Dyeing process of fabric

A fabric and process technology, applied in the field of dyeing and finishing, can solve problems such as less oxidation exploration, achieve the effect of soft, warm and comfortable hand feel, reduce cost or environmental pollution, and save equipment and space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

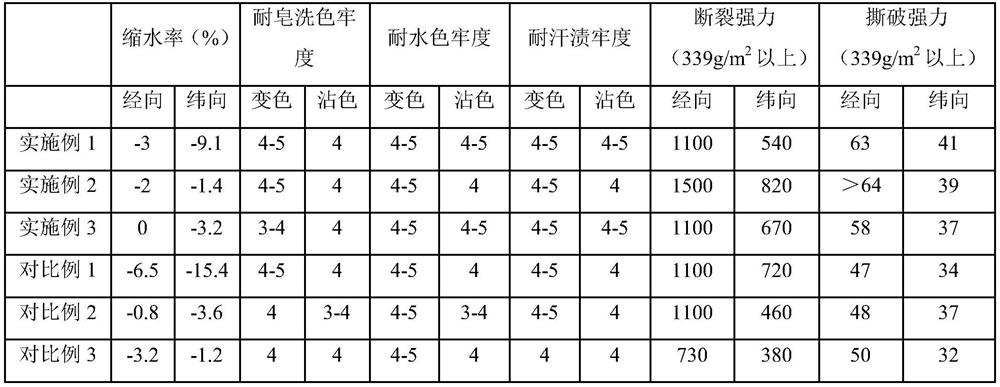

Examples

Embodiment 1

[0069] This embodiment provides a fabric dyeing process. The fabric is a denim fabric: the warp and weft yarns are all made of Taiwan Sanyong OE10, and the fabric structure is 3 / 1 right diagonal. The dyeing process steps are as follows:

[0070] (1) Singeing: Use a singeing machine to singe the fabric at a speed of 65m / min, and use two positive and one negative singeing ports;

[0071] (2) Desizing: The desizing process selects the cold pad-batch process, and the process is as follows: the concentration of desizing enzyme (high-temperature-resistant α-amylase, purchased from Baxter Biotechnology Co., Ltd.) in the desizing solution is 15g / L, silicon Sodium acid concentration is 3g / L, hydrogen peroxide (mass concentration: 30%) concentration is 23g / L, OK oil concentration is 12g / L, M oil concentration is 3g / L; temperature is 70°C, vehicle speed is 65m / min, stacked for 24h;

[0072] (3) Ozone steaming and washing: the fabric after cold pad batching is subjected to ozone steaming...

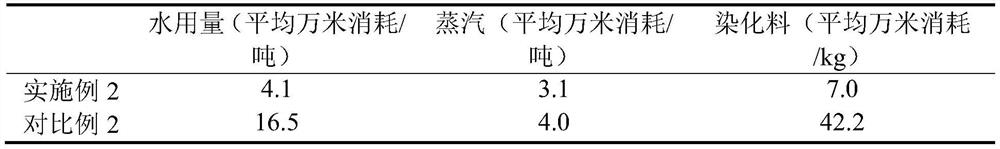

Embodiment 2

[0078] This embodiment provides a fabric dyeing process, the fabric is a denim fabric: the warp and weft yarns are respectively made of Tianhong Yinlong organic cotton 21 and Tianhong Yinlong organic cotton 21 / 70-3.5 spandex, and the fabric structure adopts 3 / 1 right diagonal . The dyeing process steps are as follows:

[0079] (1) Singeing: Use a singeing machine to singe the fabric at a speed of 65m / min, and use two positive and one negative singeing ports;

[0080] (2) Desizing: the desizing process selects the cold pad batch process, and the process is: pH is 6.0, and the concentration of desizing enzyme (high temperature resistant type α-amylase, purchased from Pasteur Biotechnology Co., Ltd.) in the desizing solution is 15g / L, the concentration of sodium silicate is 3g / L, the concentration of hydrogen peroxide (mass concentration 30%) is 23g / L, the concentration of OK oil is 10g / L, and the concentration of M oil is 3g / L; Set 23h;

[0081] (3) Ozone steaming and washin...

Embodiment 3

[0087] This embodiment is a fabric dyeing process, the fabric and dyeing process steps are the same as those in Example 1, the main difference is that the desizing process is different, and the mercerizing process is not performed.

[0088] Specific steps are as follows:

[0089] (1) Singeing: Use a singeing machine to singe the fabric at a speed of 65m / min, and use two positive and one negative singeing ports;

[0090] (2) Desizing: the desizing process adopts the alkali desizing process, and the process is: the concentration of caustic soda in the desizing solution is 15g / L, the concentration of OK oil is 3g / L; the temperature is 70°C, the speed is 65m / min, and the stacking is 18h;

[0091] (3) Ozone steaming and washing: the fabric after cold pad batching is subjected to ozone steaming and washing, and the ozone density is 10g / m 3 , steaming temperature 105 ℃, wherein oxygen bleaching formula is: hydrogen peroxide (mass concentration 30%) concentration 10g / L, OK oil concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com