Method for generating two-dimensional high-volume-fraction earth-rock mixed material geometric model

A technology with high volume fraction and mixed materials, which is applied in electrical digital data processing, instruments, design optimization/simulation, etc., can solve problems such as low efficiency, long time consumption, and affecting the accuracy of modeling results, so as to improve efficiency and improve The effect of reliability and strong application significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

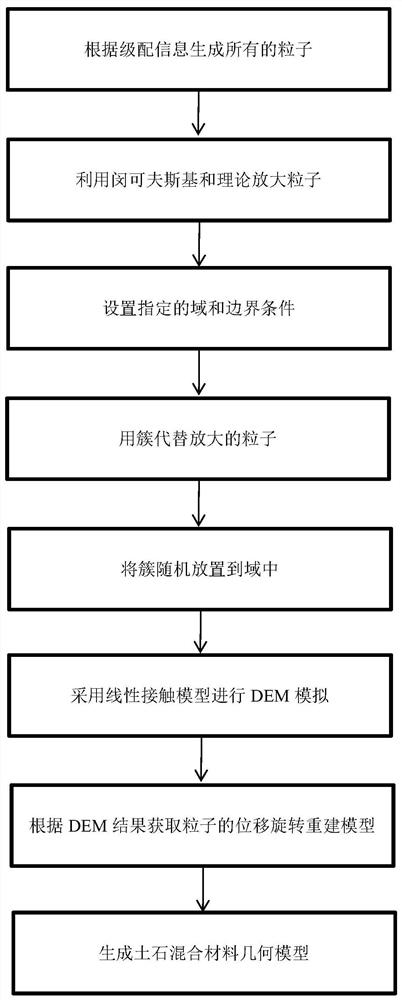

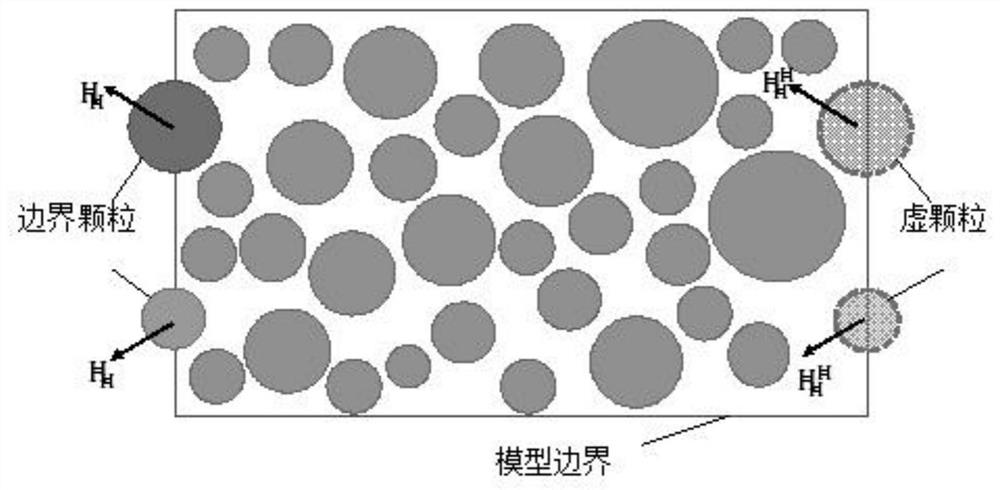

[0030] The invention provides a method for generating a geometric model of a two-dimensional high volume fraction earth-rock mixture material, such as figure 1 As shown, it specifically includes the following steps:

[0031] Step 1: Generate all particles according to the gradation information.

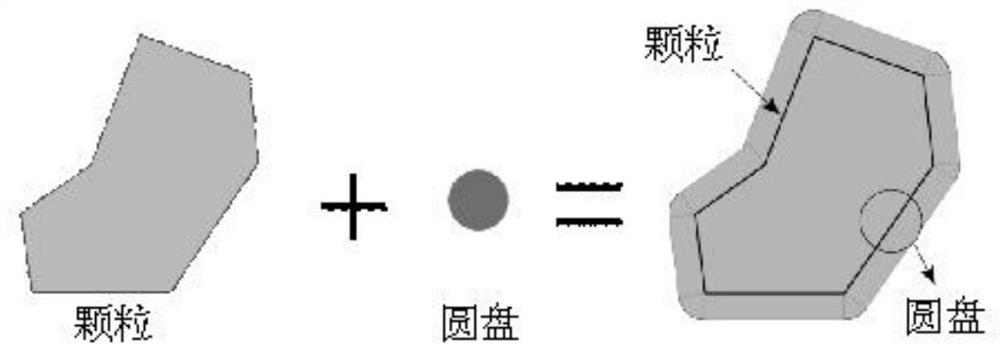

[0032] Randomly generate particles with custom particle gradation and volume fraction in the preset coordinate area. Using Matlab in the preset 50*100 Cartesian coordinate system area, Monte Carlo simulation is used to randomly generate particles with specified gradation and volume fraction. Randomly generate custom particles using Monte Carlo simulation. The shape of the particles is polygonal. The generation method is to use (0,0) as the center, specify the angle and radius, select a custom number of vertices on the circumference, and connect them in order. The method of rand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com