Method for machining bent inclined solenoid CCT skeleton through caulking groove brazing assembly process

An oblique helix and bending technology, applied in the field of special-shaped superconducting magnet skeleton processing and manufacturing, can solve the problems of unsuitable processing, restricting the development of curved CCT magnet technology, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

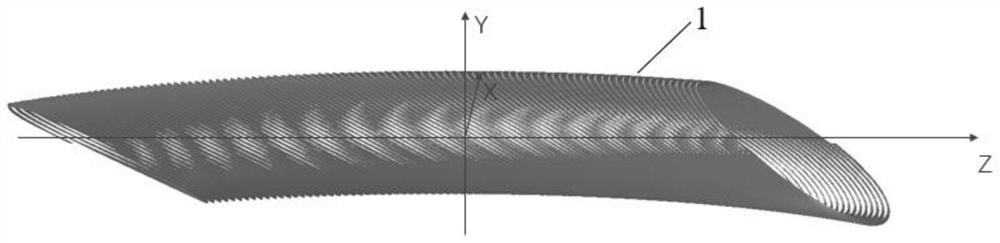

[0024] The embodiments of the present invention will be described in more detail below in conjunction with the accompanying drawings. It should be understood that the description and illustrations of the embodiments of the present invention are essentially for illustration rather than limitation of the present invention. The present invention will be further described below by taking the curved oblique helical CCT two-pole magnet skeleton as an example. The track of the curved skeleton line groove can be determined according to the curved oblique helix trajectory equation, taking the curved oblique helix CCT dipole magnet skeleton as an example, as figure 1 Shown is the trajectory of a particular curved helical coil established from the curved helical trajectory equation.

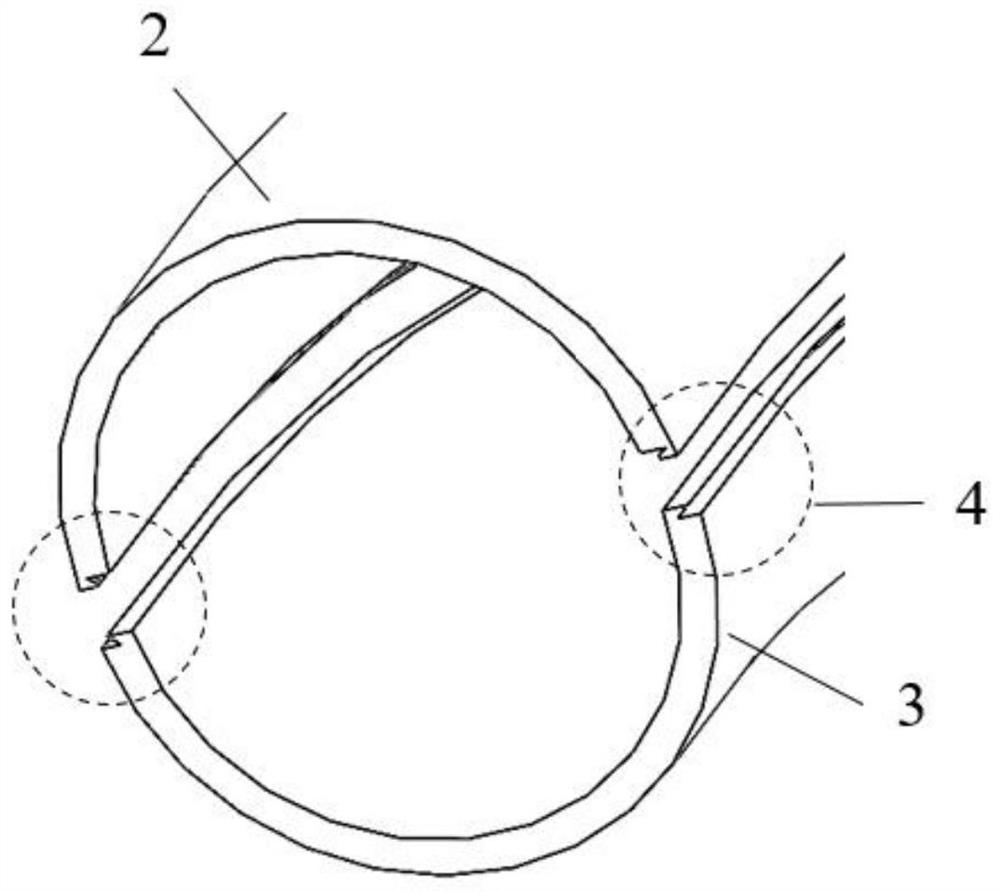

[0025] According to an embodiment of the present invention, during processing, the curved CCT skeleton is first divided into two semicircular skeletons along the radial direction (z direction) for processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com