Novel thermal barrier coating with high heat-insulating property and preparation process of novel thermal barrier coating

A technology of thermal barrier coating and preparation process, which is applied in metal material coating process, coating, melt spraying, etc. The effect of reducing thermal conductivity and improving thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing a thermal barrier coating with high thermal insulation performance on the surface of a nickel-based alloy according to the present invention, comprising the following steps:

[0022] Before preparing the thermal barrier coating, the thermal conductivity of the thermal barrier coating is simulated by Ansys Workbench software;

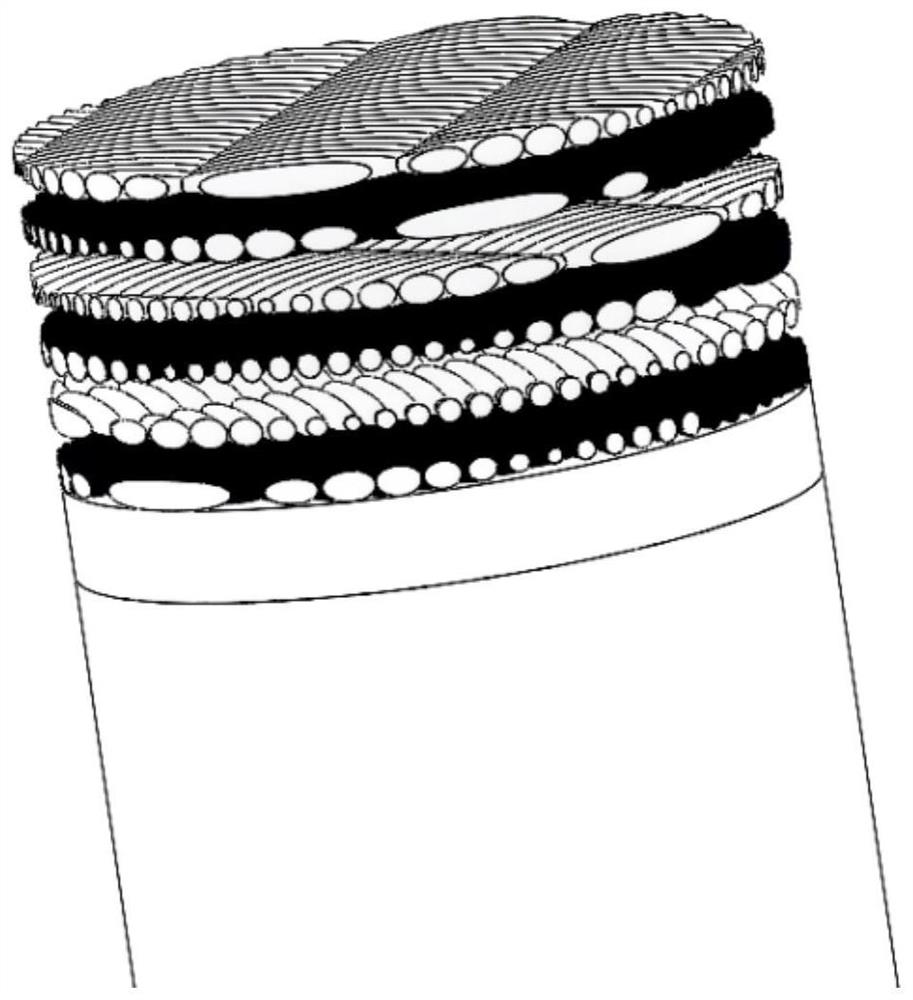

[0023] Adjust the moving speed of the plasma spray gun to 1000mm / s and the powder feeding rate to 5rad / min, and adjust the thickness of each layer of the plasma sprayed ceramic layer to 10μm;

[0024] Adjust the angle between the plasma spray gun and the workpiece to be 90 degrees. After each layer of ceramic layer coating is prepared, the positioner adjusts the horizontal rotation of the workpiece by 30 degrees clockwise, and at the same time adjusts the bonding area between layers to 0.7852mm2 / mm2;

[0025] The thermal barrier coating was prepared according to the conventional plasma spraying method, and the thickness of t...

Embodiment 2

[0027] A method for preparing a thermal barrier coating with high thermal insulation performance on the surface of a nickel-based alloy according to the present invention,

[0028] Before preparing the thermal barrier coating, the thermal conductivity of the thermal barrier coating is simulated by Ansys Workbench software;

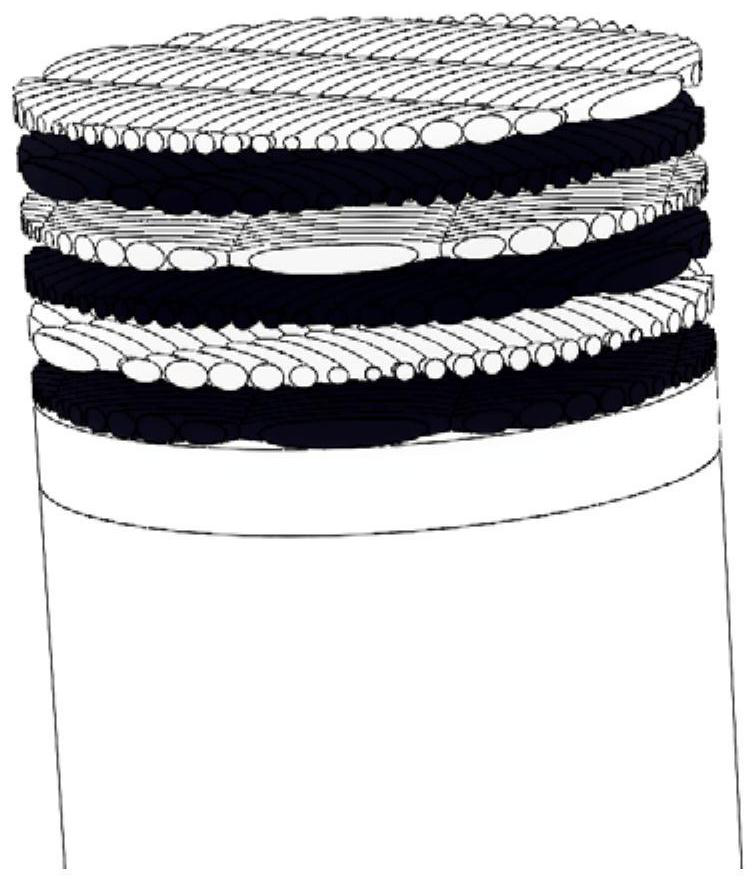

[0029] Adjust the moving speed of the plasma spray gun to 900mm / s and the powder feeding rate to 4rad / min, and adjust the thickness of each layer of the plasma sprayed ceramic layer to 8μm;

[0030] Adjust the angle between the plasma spray gun and the workpiece to be 90 degrees. After each layer of ceramic layer coating is prepared, the positioner adjusts the horizontal rotation of the workpiece by 90 degrees clockwise, and at the same time adjusts the bonding area between layers to 0.7925mm2 / mm2;

[0031] The thermal barrier coating was prepared according to the conventional plasma spraying method, and the thickness of the coating reached 200 μm. The pr...

Embodiment 3

[0033] A method for preparing a thermal barrier coating with high thermal insulation performance on the surface of a nickel-based alloy according to the present invention, comprising the following steps:

[0034] Before preparing the thermal barrier coating, the thermal conductivity of the thermal barrier coating is simulated by Ansys Workbench software;

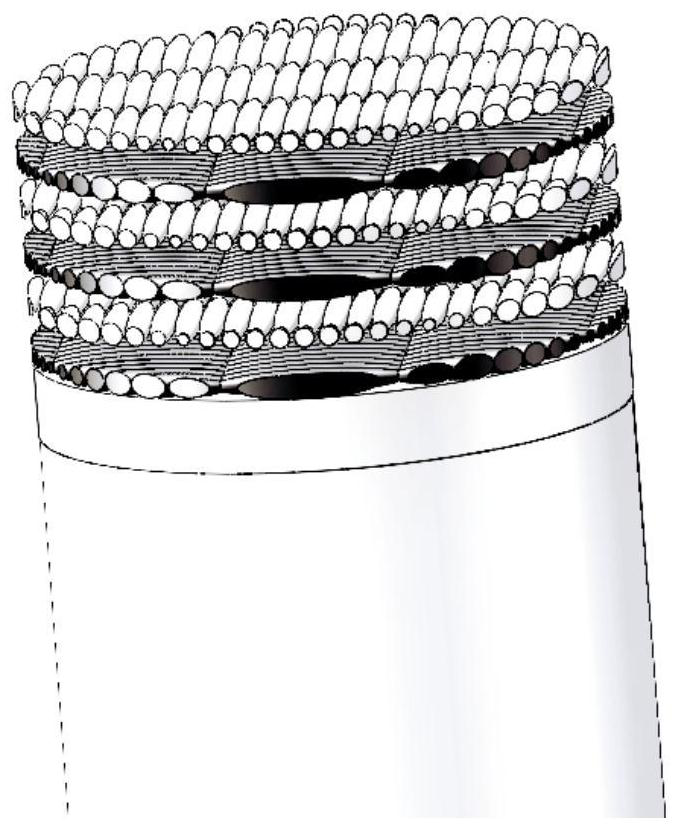

[0035] Adjust the moving speed of the plasma spray gun to 600mm / s and the powder feeding rate to 8rad / min, and adjust the thickness of each layer of the plasma sprayed ceramic layer to 20μm;

[0036] Adjust the angle between the plasma spray gun and the workpiece to be 90 degrees. After each layer of ceramic layer coating is prepared, the positioner adjusts the horizontal rotation of the workpiece by 60 degrees clockwise, and at the same time adjusts the bonding area between layers to 0.7897mm2 / mm2;

[0037] The thermal barrier coating was prepared according to the conventional plasma spraying method, and the thickness of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com