Hydrophobic and oleophobic coating as well as preparation method and product thereof

A hydrophobic and oleophobic coating technology, which can be used in coatings, metal material coating processes, gaseous chemical plating, etc., and can solve problems such as limiting the development and application of hydrophobic and oleophobic coatings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

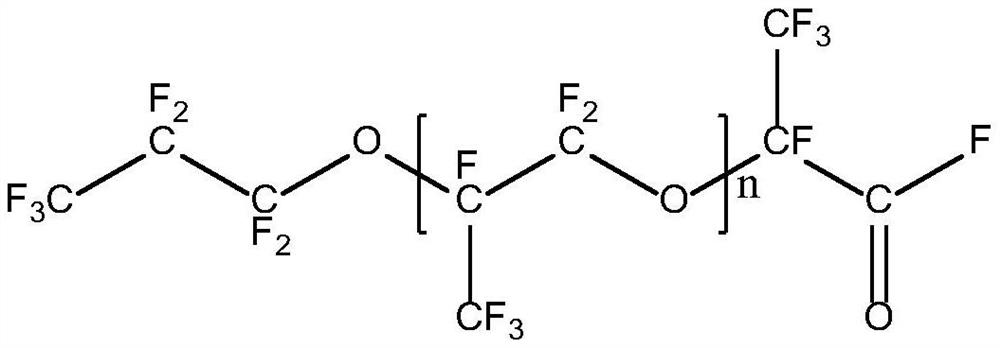

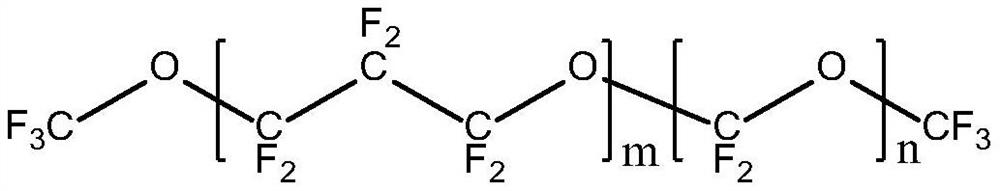

Image

Examples

Embodiment 1

[0086] Put the alcohol-wiped glass into the reaction chamber of the plasma chamber, and continuously evacuate the reaction chamber to make the vacuum degree reach 20 millitorr; feed the plasma source gas helium, the flow rate is 50 sccm, and the internal temperature of the chamber is 55 ℃, turn on the plasma discharge to pretreat the substrate, the discharge power supply adopts a pulse bias power supply in constant power mode, the power is 500W, the pulse frequency is 50KHz, the duty cycle is 10%, and the discharge time is 30 minutes.

[0087] Then the monomer raw material is vaporized and introduced into the reaction chamber. The internal temperature of the chamber is 45°C, the vaporization temperature of the monomer is 90°C, the flow rate of helium is 50 sccm, the pressure is constant at 80 millitorr, and the flow rate of the monomer is 350ul / min. In the coating stage For pulse discharge, the discharge power supply adopts a pulse bias power supply in constant power mode, with...

Embodiment 2

[0092] Put the nylon watch strap into the reaction chamber of the plasma chamber, and continuously evacuate the reaction chamber to make the vacuum degree reach 20 millitorr; inject the plasma source gas helium, the flow rate is 50 sccm, and the internal temperature of the chamber is 55 ℃, turn on the plasma discharge to pretreat the substrate, the discharge power supply adopts a pulse bias power supply in constant power mode, the power is 500W, the pulse frequency is 50KHz, the duty cycle is 10%, and the discharge time is 30 minutes.

[0093] monomer raw material HT 170 is vaporized and introduced into the reaction chamber. The internal temperature of the chamber is 50°C, the vaporization temperature of the monomer is 100°C, the flow rate of helium is 50 sccm, the pressure is constant at 80 millitorr, the flow rate of the monomer is 300ul / min, and the coating stage is pulse discharge. , The discharge power supply adopts the pulse bias power supply under constant power mode, ...

Embodiment 3

[0096] Place the alcohol-wiped glass in the vacuum coating chamber, and continuously evacuate the reaction chamber to make the vacuum degree reach 80 mTorr; inject the plasma source gas helium, the flow rate is 50 sccm, and the internal temperature of the chamber is 55 ° C. Turn on the plasma discharge to pretreat the substrate. The discharge power supply is a pulse bias power supply in constant power mode, with a power of 500W, a pulse frequency of 50KHz, a duty cycle of 10%, and a discharge time of 30 minutes.

[0097] The monomer raw material bishydroxy perfluoropolyether derivative was then D and perfluoropolyether The solutions obtained by mixing HT170 according to different mass ratios are gasified after mixing, and then introduced into the reaction chamber after gasification. Millitorr, monomer flow rate is 400ul / min, pulse discharge is used in the coating stage, the discharge power supply adopts a pulse bias power supply in constant power mode, the power is 460W, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydrophobic angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com