Thermosensitive gelatinized direct injection type textile ink and application thereof

A heat-sensitive gel and ink technology, applied in textiles, papermaking, dyeing, etc., can solve the problems of high energy consumption, cumbersome printing production process, seepage of fabric printing patterns and unclear outlines, etc., to simplify the process flow, Efficient pattern unclear problem, the effect of solving the pattern unclear problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

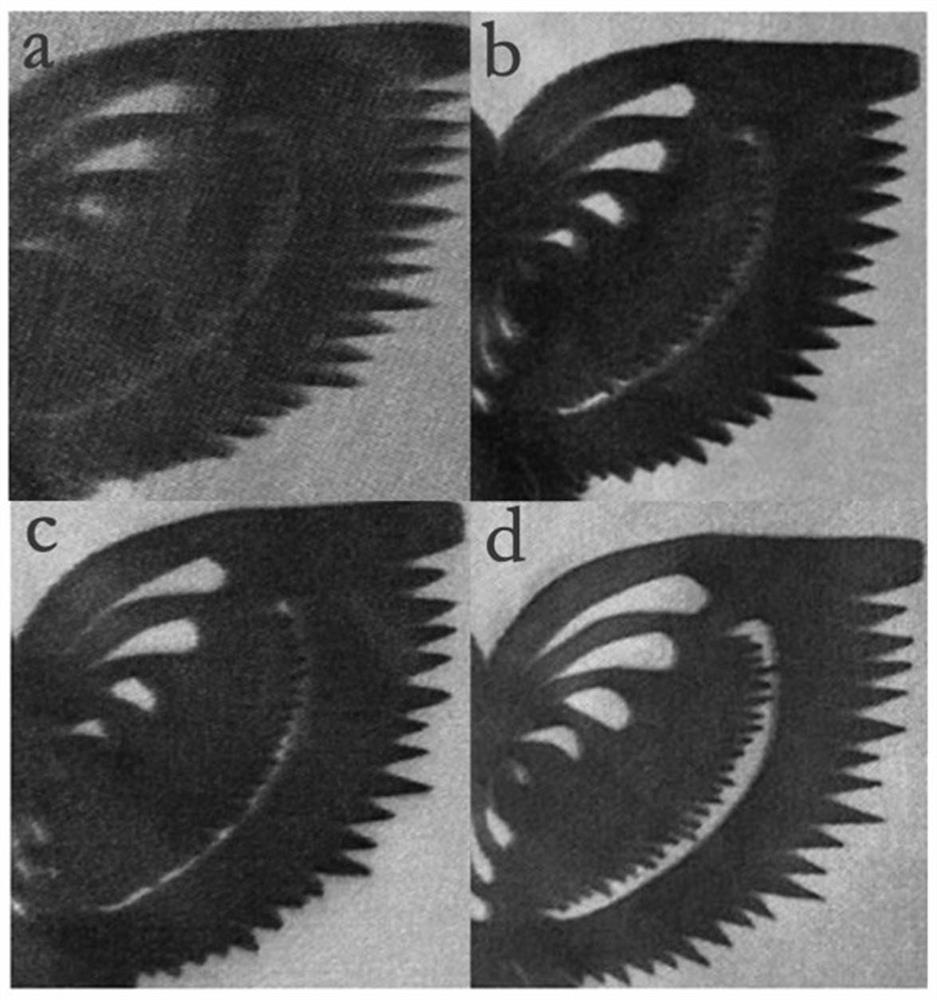

Image

Examples

Embodiment 1

[0031] This embodiment provides a yellow thermosensitive gelling free pretreatment direct injection textile ink, its components and mass parts are: C.I. Disperse Yellow 54 color paste: 30 parts, dispersant MF: 10 parts, surface active Agent Evonik 465: 1 part, organic solvent: 20 parts of glycerin and 10 parts of diethylene glycol, antibacterial agent: 0.2 parts of salicylic acid, block copolymer PCLA-PEG-PCLA: 4 parts, water: 24.8 parts.

[0032] The block copolymer provided in this embodiment can be a BAB or ABA triblock composed of polyethylene glycol (PEG) as a hydrophilic segment and polyester, polycaprolactone, polyanhydride, etc. as a hydrophobic segment. Copolymer (A represents the hydrophobic segment, B represents the hydrophilic segment), or a copolymer containing the triblock, its aqueous solution undergoes a solution-gel phase transition as the temperature rises, and the phase transition temperature is 20 ~ 80℃, with good biocompatibility and biodegradability. The...

Embodiment 2

[0040] The present embodiment provides a kind of red heat-sensitive gelling free pretreatment direct-injection textile ink, and its weight percentage is composed of: C.I. Disperse Red 60 color paste: 30 parts, dispersant MF: 10 parts, surface active Agent Evonik 465: 1 part, organic solvent: 20 parts of glycerin and 10 parts of diethylene glycol, antibacterial agent: 0.2 parts of isothiazolinone, block copolymer PCLA-PEG-PCLA: 4 parts, water: 24.8 parts.

[0041] Heat the polyester fabric to the temperature required for the sol-gel transition of the heat-sensitive gelation-free direct-injection textile ink to 50°C, and print it directly with a digital textile printing machine; fix the color: place the printed fabric at 160~ Fix the color at 180°C for 4-8 minutes to obtain a direct-injection digitally printed polyester fabric.

[0042] The particle size of the ink and the pattern definition, K / S value, washing fastness and rubbing fastness grade of the direct-injection digital pr...

Embodiment 3

[0045] The present embodiment provides a kind of blue heat-sensitive gelling free pretreatment direct-injection textile ink, and its percentage by weight is composed of: C.I. Disperse Blue 259 color paste: 30 parts, dispersant MF: 10 parts, surface Active agent Evonik 465: 1 part, organic solvent: 20 parts of glycerin and 10 parts of diethylene glycol, antibacterial agent: 0.2 parts of isothiazolinone, block copolymer PCLA-PEG-PCLA: 4 parts, water: 24.8 parts .

[0046] Heat the polyester fabric to the temperature required for the sol-gel transition of the heat-sensitive gelation-free direct-injection textile ink to 50°C, and print it directly with a digital textile printing machine; fix the color: place the printed fabric at 160~ Fix the color at 180°C for 4-8 minutes to obtain a direct-injection digitally printed polyester fabric.

[0047] The particle size of the ink and the pattern definition, K / S value, washing fastness and rubbing fastness grade of the direct-injection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com