Modified lignosulfonate paste for cationic dye printing of acrylic fabric and its preparation method and application

A technology of lignosulfonate and cationic dyes, which can be used in dyeing, textiles and papermaking. It can solve the problems of inability to disperse uniform chemical additives, high price of modified starch paste, and large viscosity changes, and achieve soaping. High level of color fastness, high color fastness to dry rubbing, and little change in viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

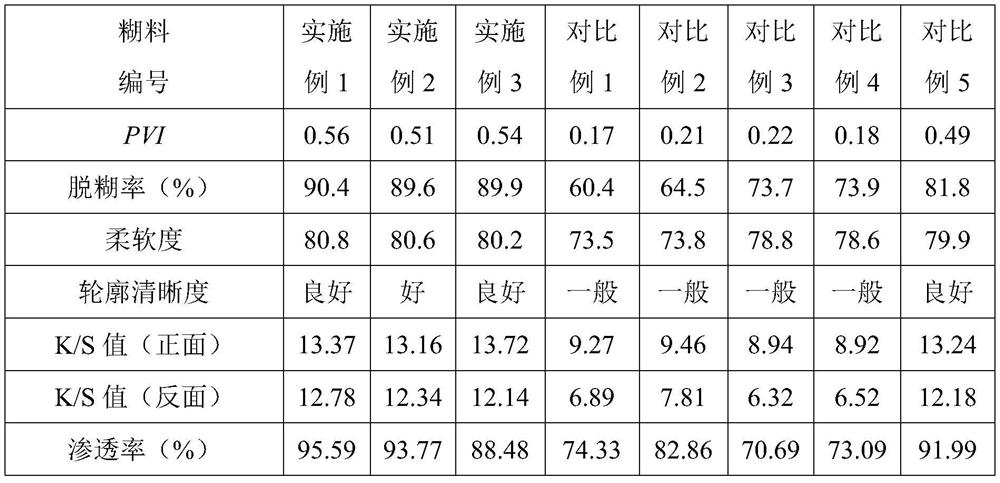

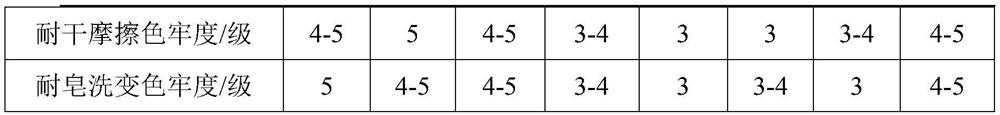

Examples

Embodiment 1

[0023] The preparation method of the modified lignosulfonate paste for cationic dye printing of acrylic fabrics, the specific method comprises the following steps:

[0024] (1) weigh 11g of sodium lignosulfonate and add it to the closed reactor, pass nitrogen into the reactor to remove the air in the upper space, add 150mL of 3wt% NaOH aqueous solution, stir and dissolve; take ethylene oxide and dissolve it in ethanol to prepare To obtain an ethanol solution containing 15wt% of ethylene oxide, slowly add 15 mL of the ethanol solution containing ethylene oxide into the reaction kettle, and carry out the reaction at 65 ° C for 7 hours; after the reaction is completed, add 150 mL of distilled water to dilute, cool to room temperature, and use ice The pH value was adjusted to 6.5 with acetic acid, and the impurities were removed by centrifugation; the supernatant was slowly added to 4 times the volume of 95% ethanol, left for 3 h, suction filtered to obtain a filter cake, washed wi...

Embodiment 2

[0028] The preparation method of the modified lignosulfonate paste for cationic dye printing of acrylic fabrics, the specific method comprises the following steps:

[0029] (1) weigh 10g of sodium lignosulfonate and add it to the closed reactor, pass nitrogen into the reactor to remove the air in the upper space, add 100mL of 2wt% NaOH aqueous solution, stir and dissolve; take ethylene oxide and dissolve it in ethanol to prepare To obtain an ethanol solution containing 10wt% of ethylene oxide, slowly add 10 mL of the ethanol solution containing ethylene oxide into the reaction kettle, and carry out the reaction at 60 ° C for 6 hours; after the reaction, add 100 mL of distilled water to dilute, cool to room temperature, and use ice The pH value was adjusted to 6 with acetic acid, and the impurities were removed by centrifugation; the supernatant was slowly added to 3 times the volume of 95% ethanol, allowed to stand for 2 hours, and the filter cake was obtained by suction filtra...

Embodiment 3

[0033] The preparation method of the modified lignosulfonate paste for cationic dye printing of acrylic fabrics, the specific method comprises the following steps:

[0034] (1) Weigh 12g of sodium lignosulfonate and add it to a closed reactor, pass nitrogen into the reactor to remove the air in the upper space, add 200mL of 4wt% NaOH aqueous solution, stir and dissolve; take ethylene oxide and dissolve it in ethanol to prepare To obtain an ethanol solution containing 20wt% of ethylene oxide, slowly add 20 mL of the ethanol solution containing ethylene oxide into the reaction kettle, and carry out the reaction at 70 ° C for 8 hours; after the reaction, add 200 mL of distilled water to dilute, cool to room temperature, use ice The pH value was adjusted to 7 with acetic acid, and impurities were removed by centrifugation; the supernatant was slowly added to 5 times the volume of 95% ethanol, allowed to stand for 4 h, filtered to obtain a filter cake, washed with absolute ethanol, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com