Soft magnetic powder compound, magnetic powder core material and insulating coating method based on organic matter growth

A soft magnetic powder, insulating coating technology, applied in the direction of inorganic material magnetism, inductance/transformer/magnet manufacturing, electrical components, etc. , low uniformity of ferrite coating, etc., to achieve the effect of reducing dilution effect, improving magnetic properties, and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

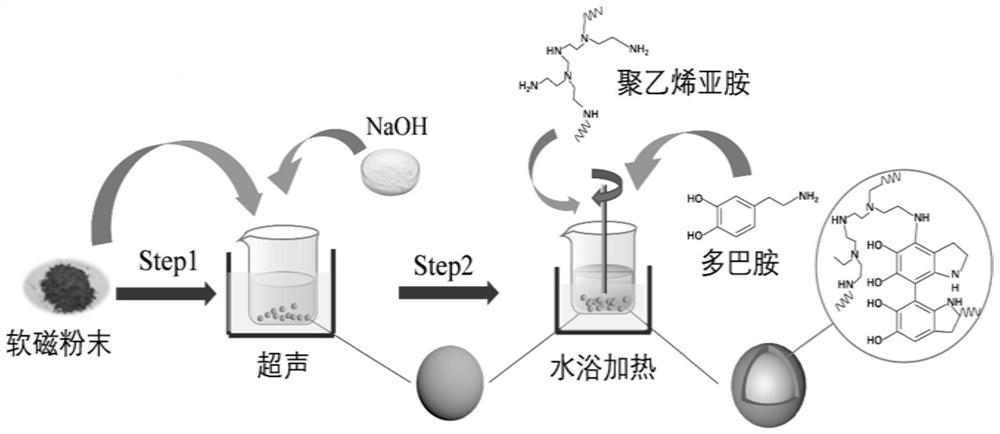

Method used

Image

Examples

Embodiment 1

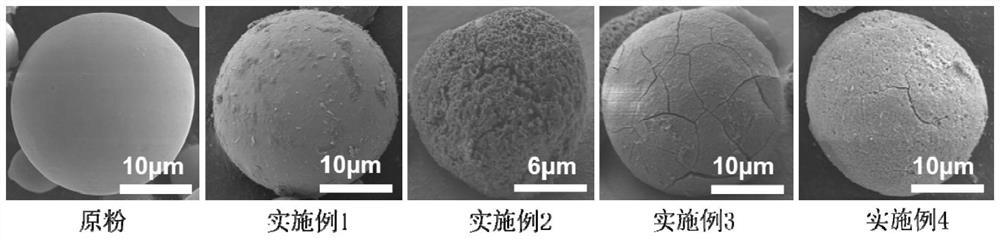

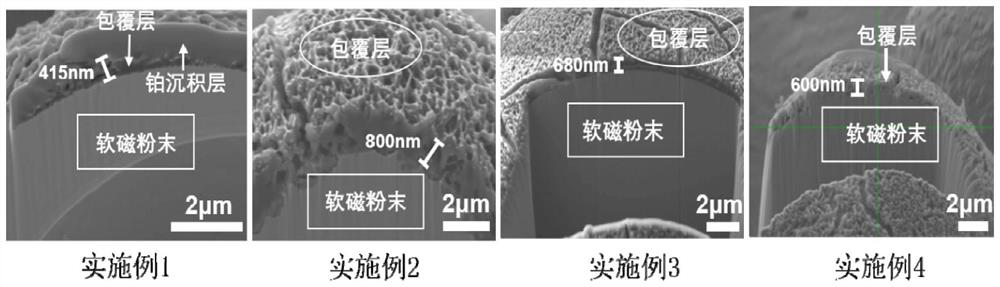

[0072] 30g of particle size D 50 Fe-Si-B-C-Cr alloy soft magnetic raw powder of 25 μm is placed in 500mL0.5mol / L NaOH solution for 30min, then taken out and washed with deionized water until the pH value is neutral;

[0073] Put the soft magnetic powder taken out above into 60 mL of polyethyleneimine (molecular weight 1800) solution with a concentration of 50 mg / mL and sonicate for 30 min;

[0074] Dopamine and polyethyleneimine are simultaneously put into 500mL0.05mol / L Tris-HCl solution according to the mass ratio of 2:1, wherein the concentrations of dopamine and polyethyleneimine are 8mg / mL and 4mg / mL respectively, to obtain Tris-HCl / DA+PEI solution, and the above-mentioned soft magnetic powder added to the Tris-HCl / DA+PEI solution after ultrasonic treatment of polyethyleneimine solution;

[0075] The above mixed solution was mechanically stirred for 24 hours while heating at a constant temperature of 40°C, and dried to obtain a soft magnetic powder composite;

[0076] T...

Embodiment 2

[0081] 30g of particle size D 50 Fe-Si-B-C-Cr soft magnetic raw powder of 25 μm was placed in 500 mL of NaOH solution with a concentration of 0.5 mol / L and ultrasonically treated for 30 minutes, then taken out and washed with deionized water until the pH value was neutral;

[0082] Put the soft magnetic powder taken out above into 60 mL of polyethyleneimine (molecular weight 600) solution with a concentration of 50 mg / mL and sonicate for 30 min;

[0083] Dopamine and polyethyleneimine with a mass ratio of 1:1 are simultaneously put into 0.1mol / L Tris-HCl solution, wherein the concentrations of dopamine and polyethyleneimine are both 12 mg / mL to obtain Tris-HCl / DA +PEI solution, and the above-mentioned soft magnetic powder after ultrasonic treatment in polyethyleneimine solution is added to Tris-HCl / DA+PEI solution;

[0084] The above mixed solution was heated at a constant temperature of 25°C while being mechanically stirred for 30 hours and dried to obtain a soft magnetic po...

Embodiment 3

[0090] 30g of particle size D 50 Fe-Si-B-C-Cr soft magnetic raw powder of 25 μm was placed in 500 mL of NaOH solution with a concentration of 0.5 mol / L and ultrasonically treated for 30 minutes, then taken out and washed with deionized water until the pH value was neutral;

[0091] Put the soft magnetic powder taken out above into 60 mL of polyethyleneimine (molecular weight 600) solution with a concentration of 50 mg / mL and sonicate for 30 min;

[0092] Dopamine and polyethyleneimine (molecular weight 600) with a mass ratio of 2:1 were simultaneously put into 0.1mol / L Tris-HCl solution, wherein the concentrations of dopamine and polyethyleneimine were 8mg / mL and 4mg / mL respectively, Obtain Tris-HCl / DA+PEI solution;

[0093] Add the above-mentioned soft magnetic raw powder after ultrasonic treatment in the polyethyleneimine solution to the above-mentioned Tris-HCl / DA+PEI solution, heat at a constant temperature of 60 degrees Celsius, mechanically stir for 8 hours, and dry to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com