Preparation method of solar cell module, solar cell module and photovoltaic system

A technology for solar cells and battery components, applied in the field of solar cells, can solve problems such as poor packaging effect, achieve the effects of uniform distribution, prolong life, improve sealing performance and packaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

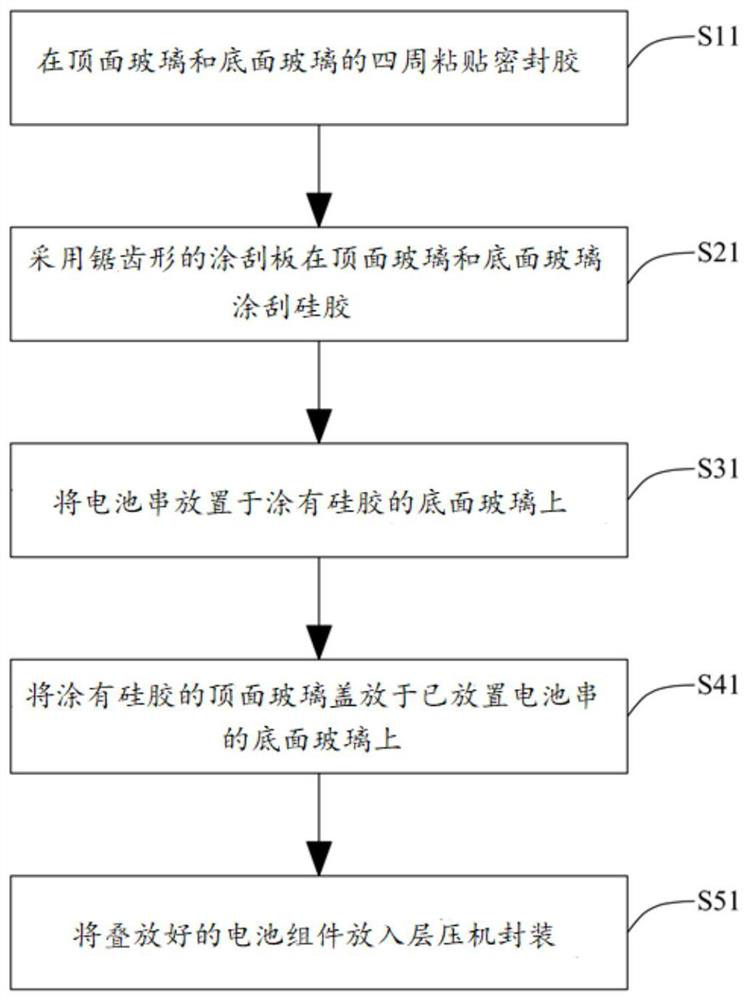

[0034] see figure 1 , figure 1 It is a schematic flow chart of the solar cell module preparation method provided by the first embodiment of the present invention. For the convenience of description, only the parts related to the embodiment of the present invention are shown. The preparation method is used to prepare the solar cell module as described above, specifically , the method includes:

[0035] Step S11, pasting a sealant 30 with water-blocking properties around the bottom glass 10 and the top glass 20;

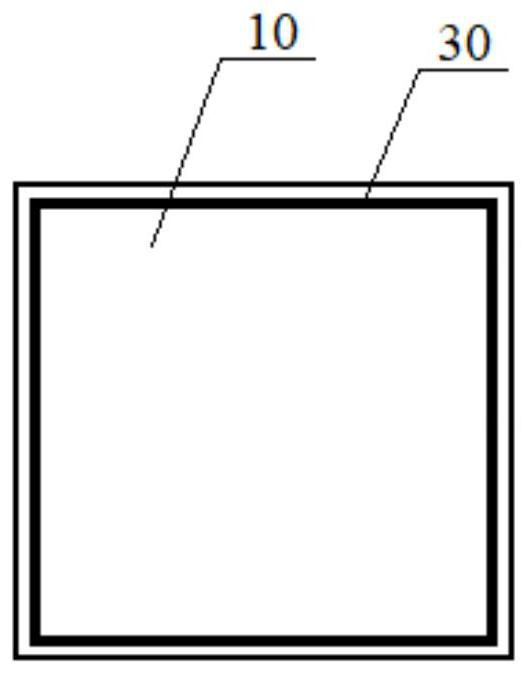

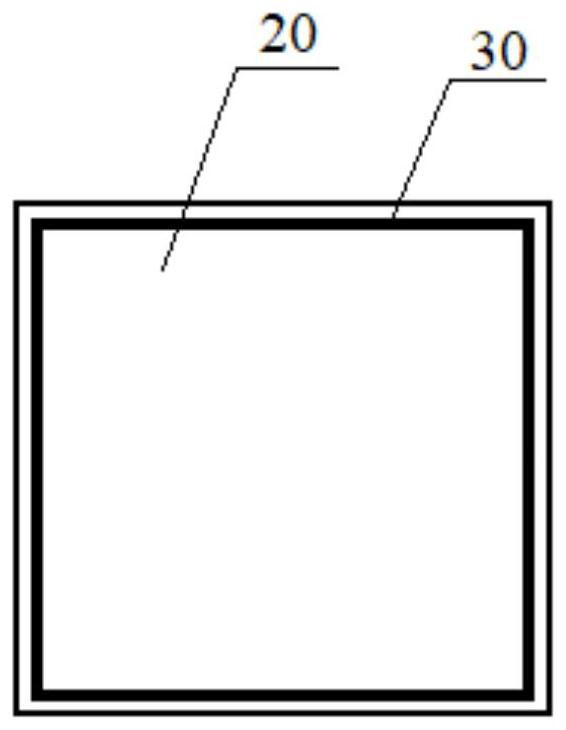

[0036] refer to figure 2 with image 3 , in the embodiment of the present invention, the sealant 30 is pasted around the sides of the bottom glass 10 and the top glass 20 that are in contact with the cells, and the sealant 30 has a certain distance from the edge of the bottom glass 10 or the top glass 20 . For example: leave a distance of 2 mm to allow the sealant 30 to laminate and overflow out of the gap. Specifically, a ring of sealant 30 is pasted around the ...

Embodiment 2

[0069] The second embodiment of the present invention also provides a solar cell assembly, which is manufactured according to the manufacturing method of the solar cell assembly in the foregoing embodiment.

[0070] The solar cell module includes: a top glass 20, a battery string and a bottom glass 10 arranged in sequence from top to bottom, the top glass 20, the bottom glass 10 and the battery string are sealed with silica gel, and the edges of the top glass 20 and the bottom glass 10 are It is sealed with a water-blocking sealant.

[0071] The solar cell module in this embodiment is prepared by the preparation method proposed in the embodiment of the present invention. Compared with the solar cell module encapsulated by the existing encapsulation material, this embodiment adopts a zigzag scraping tool Apply the silica gel evenly to the top glass and the bottom glass, and form triangular concave-convex grooves on the surface of the silica gel after coating and scraping. The t...

Embodiment 3

[0073] The third embodiment of the present invention also provides a photovoltaic system, including the solar cell assembly as described in the foregoing embodiments.

[0074] In the photovoltaic system in this embodiment, in the preparation method of the solar cell module, the silica gel is evenly applied to the top glass and the bottom glass by using a zigzag scraping tool, and triangular concave-convex grooves are formed on the surface of the silica gel after coating and scraping. The triangular concave-convex grooves formed on the surface of silica gel are conducive to the uniform distribution of silica gel and the discharge of air bubbles during the coating and scraping process, which is further conducive to the extraction of air bubbles during the lamination process, which solves the problem of air bubbles and bubbling that are easy to occur when silica gel encapsulates solar cell modules to improve the sealing performance of silica gel; in addition, butyl rubber with wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com