Air compressor with self-cleaning type condenser pipe

A condensing tube and air compressor technology, which is applied in the field of air compressors, can solve problems such as affecting gas cooling efficiency, reducing cooling water heat dissipation, and pipeline damage, and achieves the goals of improving dirt cleaning efficiency, reducing viscosity, and increasing output coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

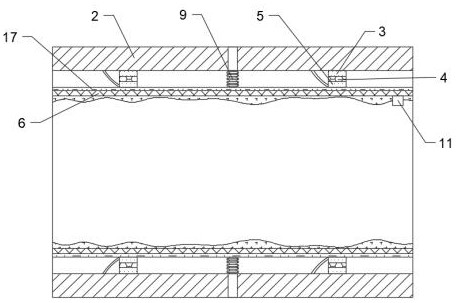

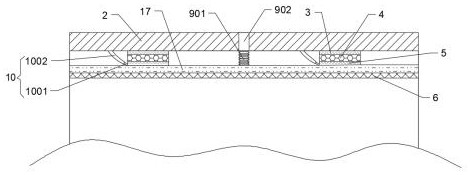

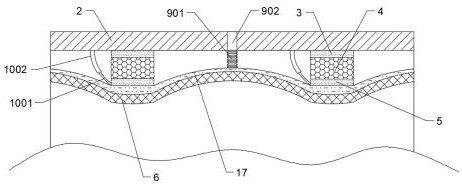

[0040] see Figure 1-7 and Figure 9 , an air compressor with a self-cleaning condensing tube, comprising an air compressor body 1 and a condensing tube 2 installed in the air compressor body 1, the condensing tube 2 is fixedly connected with a scale adhesive layer 17 inside, and the condensing tube 2 A plurality of upper flexible conductive layers 3 are fixedly installed on the inner wall, and the side of the upper flexible conductive layer 3 away from the condensation pipe 2 is fixedly connected with an expanded deformation layer 4, and the side of the expanded deformable layer 4 far away from the upper flexible conductive layer 3 is connected with a lower flexible conductive layer. layer 5, and the lower flexible conductive layer 5 is fixedly connected to the scale adhesive layer 17, and the inner wall of the condensation pipe 2 is fixedly connected with a plurality of auxiliary stripping assemblies 9, and the plurality of auxiliary stripping assemblies 9 and the plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com