Optical proximity correction method for corner-to-corner structure in layout

An optical proximity correction and diagonal technology, which is applied in the direction of optics, photographic process of pattern surface, and originals for photomechanical processing, etc., can solve the problem that the distance between the outer corner and the corner is not enough, and the distance between the inner graphics is not enough. , MRC error reporting and other issues to achieve the effect of reducing the risk of defects, reducing the risk of shrinkage or even falling off, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described below in conjunction with the accompanying drawings and embodiments.

[0032] The present invention discloses a method for angular layout of the optical proximity correction method of the corner structure, characterized by comprising the steps of:

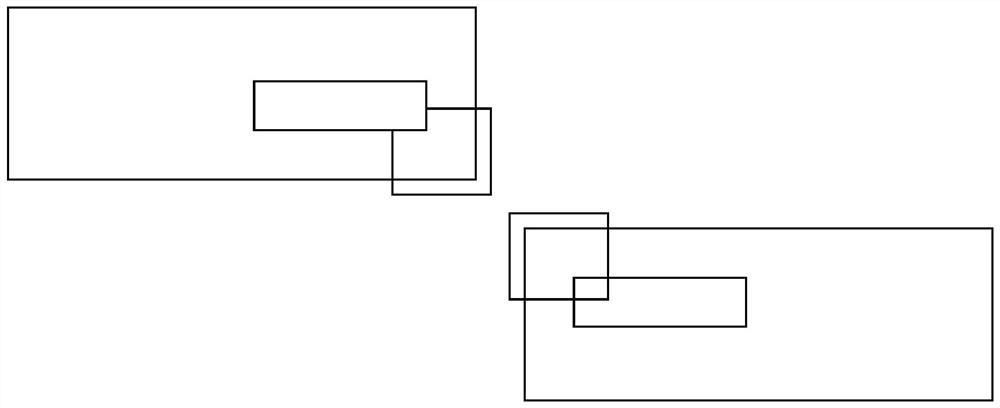

[0033] Step S1, the ion-implanted layer to identify the original pattern layout photolithography; the original pattern is a pattern of the angle corner structure.

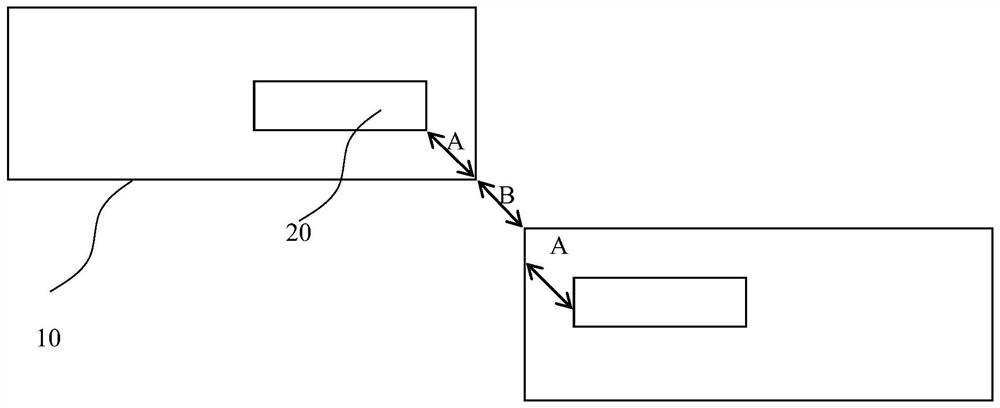

[0034] Preferably, in step S1, the original pattern is a process when a layer pattern 10, when the covering layer of the process graphic pattern before the process layer on a substrate in a direction orthogonal projection 20.

[0035] Process front layer pattern may be the FIN (fin), or may be GATE (gate).

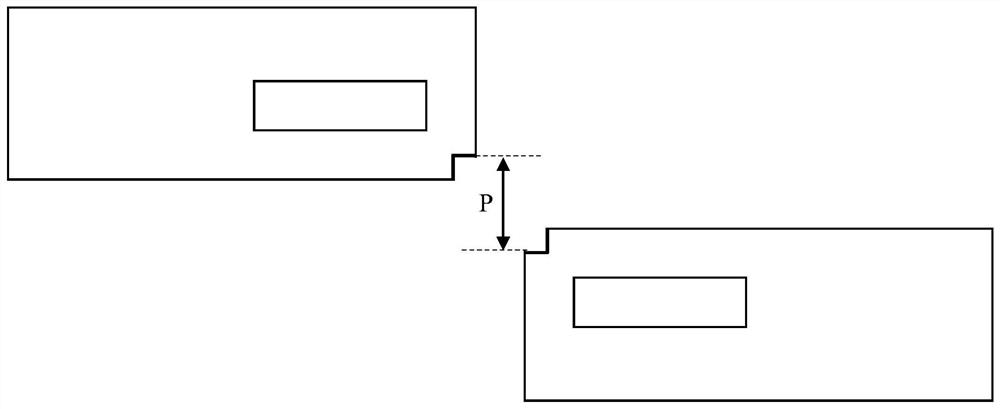

[0036] Step S2, the original corners of the original pattern, respectively, a cut angle; obtain gapped corner portion.

[0037] Preferably, in step S2, the vertical pitch P between each two opposite corner portions of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com