Preparation method and application of self-supporting membrane electrode

A self-supporting film and electrode technology, which is applied in the direction of circuits, fuel cells, electrical components, etc., can solve the problems of reduced catalyst active area, weak combination between platinum catalyst and base layer, and affecting battery performance, so as to avoid dissolution and Austrian Effects of Swald ripening, enhanced redox reaction performance, and improved catalyst performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

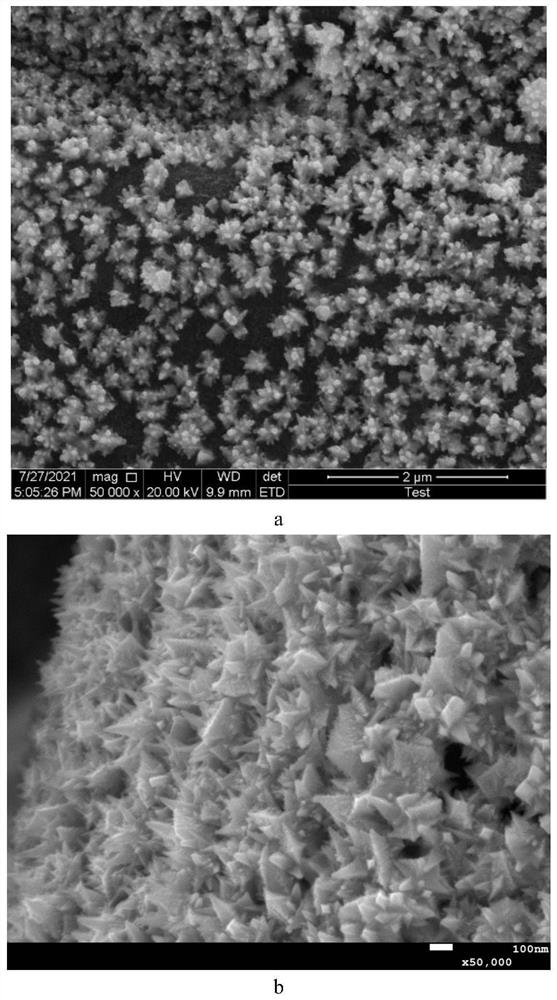

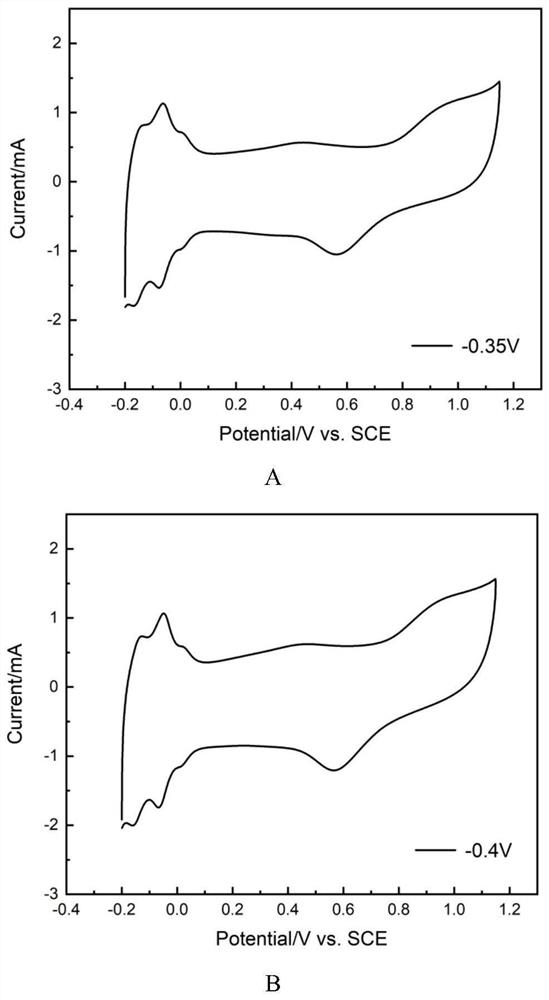

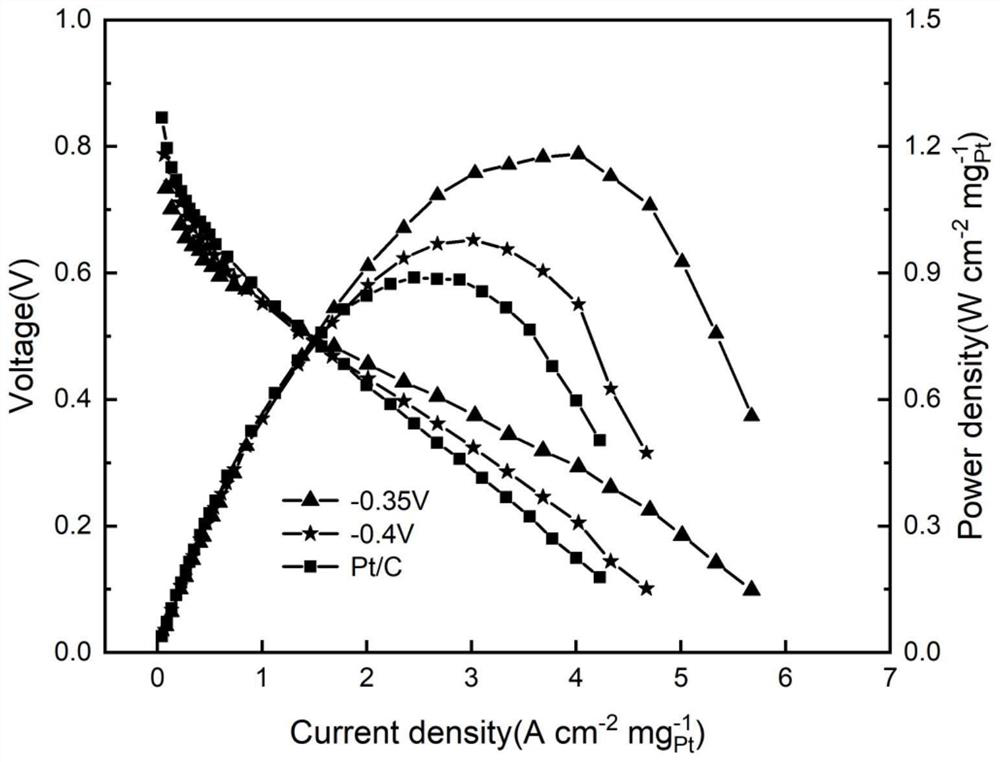

[0030] Electrodeposition of platinum catalyst fuel cell electrode with nano flower shape and special morphology, and discharge test. The main steps are as follows:

[0031] (1) Treatment of the electrode base layer: use carbon paper as the electrode base layer, and cut it into an appropriate size of 1×2.5cm 2 , and then washed in heated acetone for 15 minutes to remove dirt and functional groups on the surface of the carbon paper, and then ultrasonically washed in deionized water for 15 minutes to wash off the acetone on the surface;

[0032] (2) Preparation of hydrophilic electrode base layer: put the carbon paper processed in (1) into H 2 SO 4 and HNO 3 In the mixed acid, the proportion of the mixed acid is 98wt%H 2 SO 4 : 68wt% HNO 3 =2:1, ultrasonic for 30min, ultrasonic for 15min in deionized water, washed with deionized water for 3 times, placed in 0.5M H 2 SO 4 in standby;

[0033] (3) Prepare the solution used for deposition: take 1g H 2 PtCl6 The powder was ...

Embodiment 2

[0039] Electrodeposition of thorny special morphology platinum catalyst fuel cell electrode, and discharge test. The main steps are as follows:

[0040] (1) Treatment of the electrode base layer: use carbon paper as the electrode base layer, and cut it into an appropriate size of 1×2.5cm 2 , and then washed in heated acetone for 15 minutes to remove dirt and functional groups on the surface of the carbon paper, and then ultrasonically washed in deionized water for 15 minutes to wash off the acetone on the surface;

[0041] (2) Preparation of hydrophilic electrode base layer: put the carbon paper processed in (1) into H 2 SO 4 and HNO 3 In the mixed acid, the proportion of the mixed acid is 98wt%H 2 SO 4 : 68wt% HNO 3 =2:1, ultrasonic for 30min, ultrasonic for 15min in deionized water, washed with deionized water for 3 times, placed in 0.5M H 2 SO 4 in standby;

[0042] (3) Prepare the solution used for deposition: take 1g H 2 PtCl 6 The powder was diluted with 100 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com