Integrated chip tube body and pin detection system

An integrated chip and detection system technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of time-consuming, labor-intensive, inaccurate detection, etc., and achieve simple structure, improved rotation stability, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the embodiments described in the present invention are some of the embodiments of the present invention, not all of them .

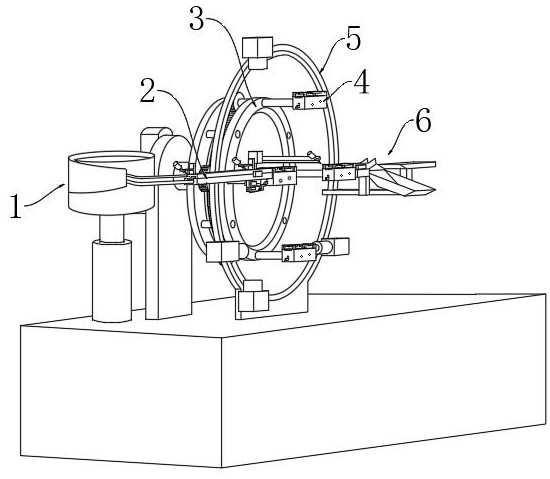

[0039] This embodiment provides an integrated chip body and pin detection system, such as figure 1 As shown, it is set on the workbench and connected with the vibrating plate 1. The vibrating plate 1 is used to transport the integrated chip 7 to be tested to the detection system through vibration. The detection system includes a feeding mechanism 2, a rotating mechanism 3, and a segmented track 4 , detection mechanism 5, discharge mechanism 6.

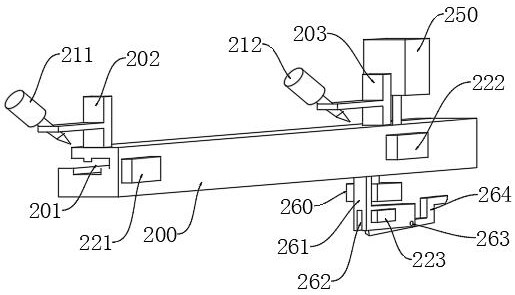

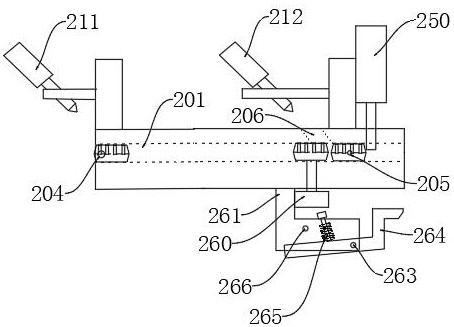

[0040] Such as figure 1 , Figure 4 , Figure 5As shown, the rotating mechanism 3 includes a rotating drive assembly 310, a rotating ring frame 320, and a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com