Three-section type lifting board rotary kiln device suitable for direct thermal desorption of organic contaminated soil, and using method thereof

A technology of organic pollution and thermal desorption, applied in the restoration of polluted soil, etc., can solve the problems of slow heat transfer rate, low unit processing capacity, and low integration level, so as to increase the rate of temperature increase, ensure the effect of desorption, The effect of increasing the amount of desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

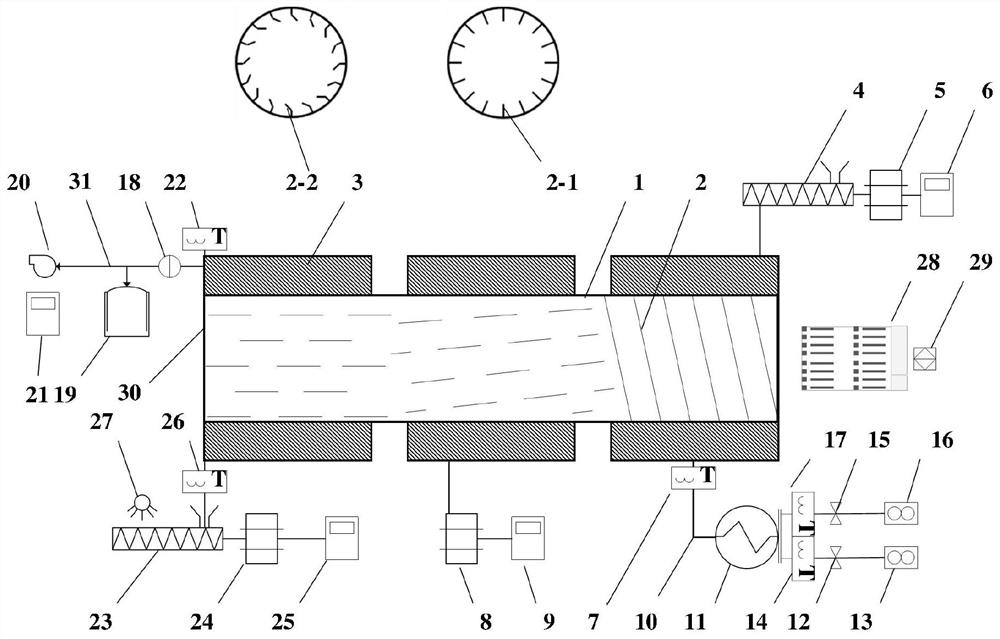

[0045] Embodiment 1. A three-stage lifting plate rotary kiln device suitable for direct thermal desorption of organic polluted soil, such as figure 1 As shown, it includes direct thermal desorber, heating system, centralized control system, temperature detection device, soil feeding system and soil discharging system.

[0046] The heating system, centralized control system, temperature detection device, tail gas treatment system, soil feeding system and soil discharging system are all connected with the direct thermal desorber.

[0047] In order to improve the utilization rate of energy consumption in the remediation process of organic polluted soil to reduce energy loss; the direct thermal desorber includes a kiln body 1 and an insulation layer 3 arranged in a horizontal direction; the upper part of the kiln body 1 is provided with three insulation layers 3 .

[0048] A glass observation port 30 is arranged at the horizontal central end of the tail of the kiln body 1 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com