T-shaped clamping groove press-locking type aluminum alloy grating structure and sectional material

A technology of aluminum alloy and aluminum profile, which is applied in the field of T-shaped card slot press-lock aluminum alloy grating structure and profile, can solve the problems of low recycling rate, short service life, and easy corrosion of the surface, and achieve high accuracy, Easy to use and maintain, easy to make

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in combination with specific embodiments. Wherein, the accompanying drawings are for illustrative purposes only, and represent only schematic diagrams, rather than physical drawings, and should not be construed as limitations on this patent; in order to better illustrate the embodiments of the present invention, some parts of the accompanying drawings may be omitted, Enlargement or reduction does not represent the size of the actual product; for those skilled in the art, it is understandable that some well-known structures and their descriptions may be omitted in the drawings.

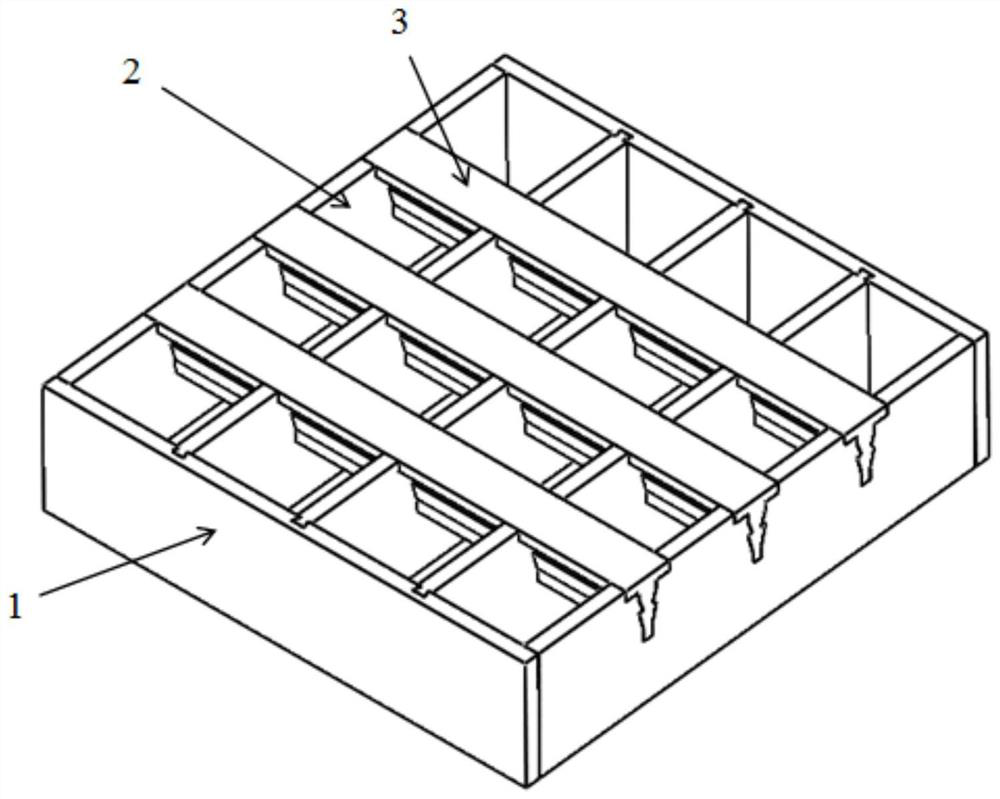

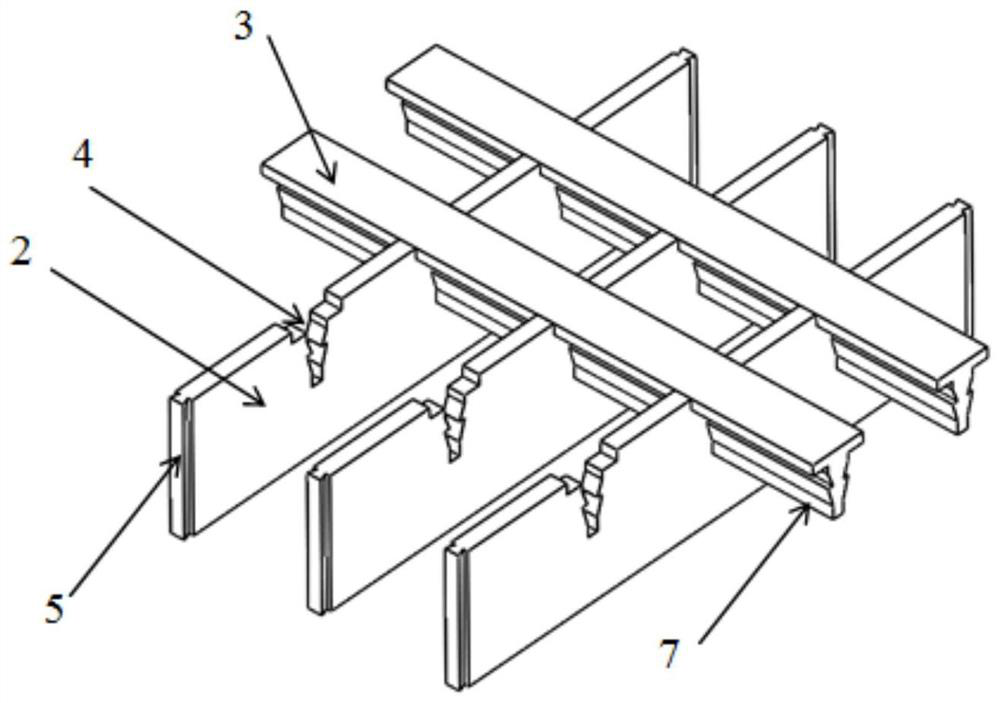

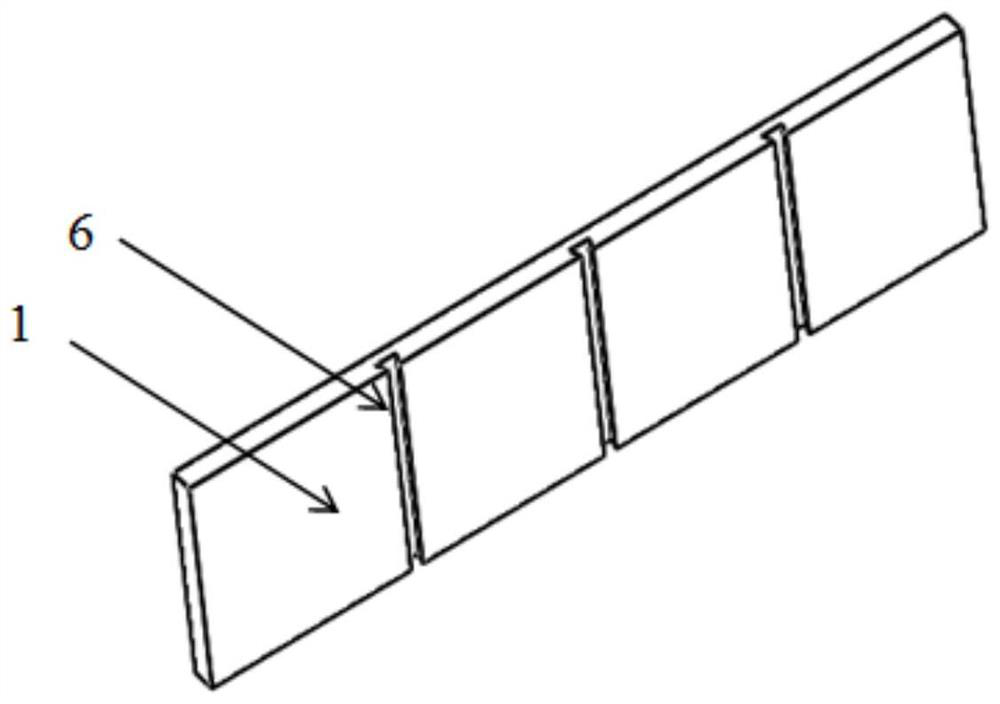

[0030] Such as Figure 1-4 As shown, a T-slot press-lock aluminum alloy grating structure mentioned in this embodiment is used in the construction industry and the field of industrial profiles, so the 6061 aluminum alloy is selected as the raw material for processing and production. The main alloying elements of 6-series aluminum alloy are A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com