Efficient metal bar detection device and control system thereof

A technology of metal rods and detection devices, applied in the field of laboratory detection, can solve problems such as low work efficiency, large measurement errors, and cumbersome work, and achieve the effects of reducing workload, improving efficiency, and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

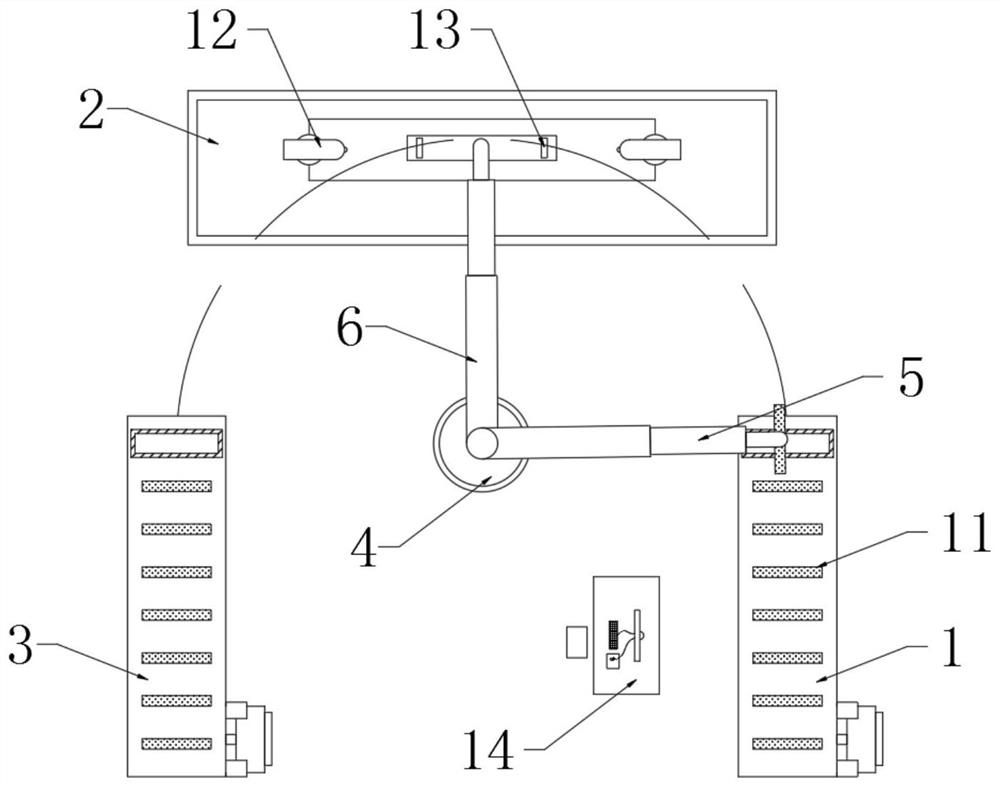

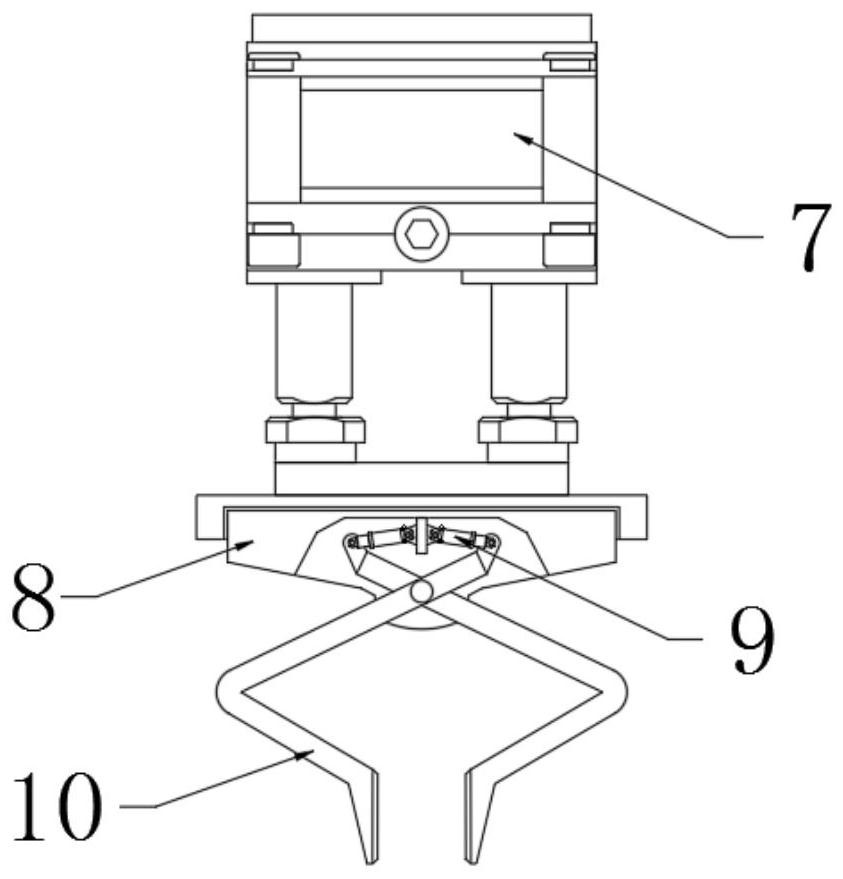

[0029] Example 1: Please refer to Figure 1-2 , the present invention provides a high-efficiency metal rod detection device: comprising a feeding mechanism 1, a rod detection machine 2, a feeding mechanism 3 and an operation table 14, and the two ends of the top of the rod detection machine 2 are symmetrically installed with a positioning light source 12 , and the middle position of the top of the positioning light source 12 is fixedly installed with a detection and positioning tool 13, and the length and weight of the metal rod body 11 are measured through two positioning light sources 12 and an electronic scale, and the measured data are stored in the corresponding folder. The saved data is read and uploaded to the MES system through the data acquisition software. A rotary drive assembly 4 is installed between the feeding mechanism 1, the bar inspection machine 2 and the unloading mechanism 3, and the top of the rotary drive assembly 4 is installed with a first mechanical Th...

Embodiment 2

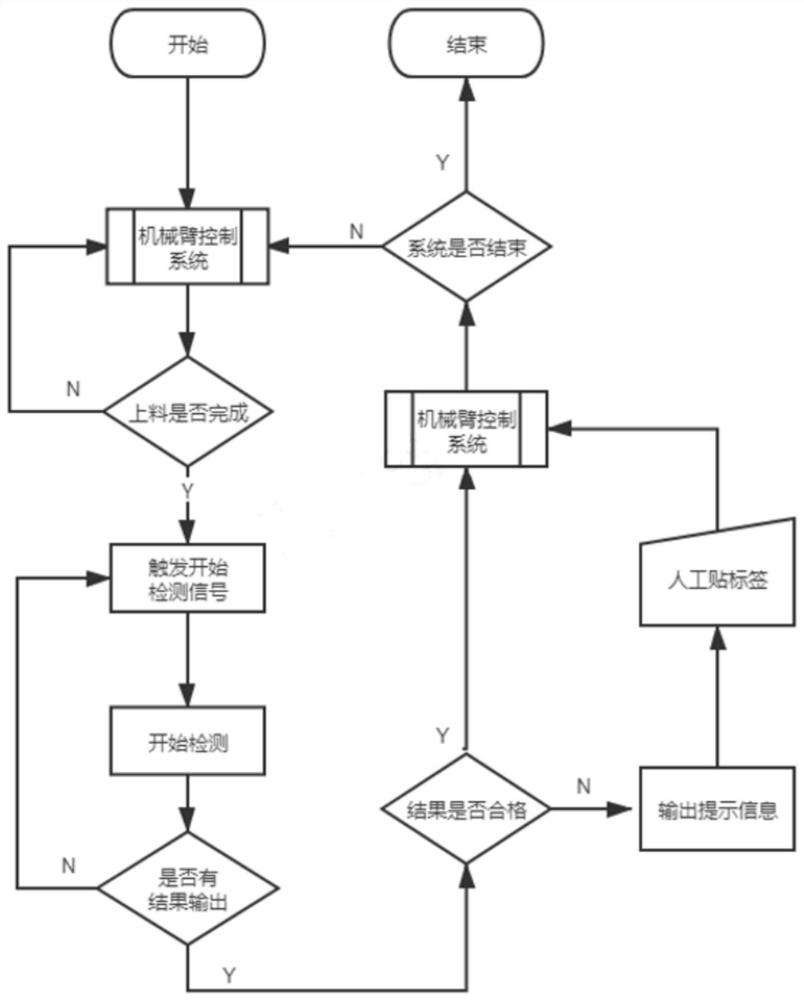

[0035] Example 2: Please refer to Figure 3-5 , the present invention provides a control system for a high-efficiency metal bar detection device: the included firmware and system flow:

[0036] The control system also includes the following firmware: the system must be equipped with PLC controller, stepping motor, cylinder, sensor photoelectric, magnetic induction, contactor and relay; 0.6MP compressed air, DC24V switching power supply (150W-200W) and AC220V power supply;

[0037] Process 1: Press the start button after the machine is reset, and the feeding belt in the feeding mechanism 1 will feed at a slow speed. When it is detected that there are parts to be inspected at the feeding level, the feeding mechanism 1 will stop feeding;

[0038]Process 2: When the detection completion signal of the bar detector 2 is received, the first mechanical arm 5 descends to the lower limit and then clamps the metal rod 11, and the first mechanical arm 5 rises to the upper limit when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com