Preparation method of negative thermal expansion metamaterial sandwich panel based on topological optimization design

A technology of negative thermal expansion and topology optimization, applied in computer material science, constraint-based CAD, multi-objective optimization, etc., can solve problems affecting structural work accuracy, high cost, large deformation, etc., and achieve multiple design degrees of freedom and good performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

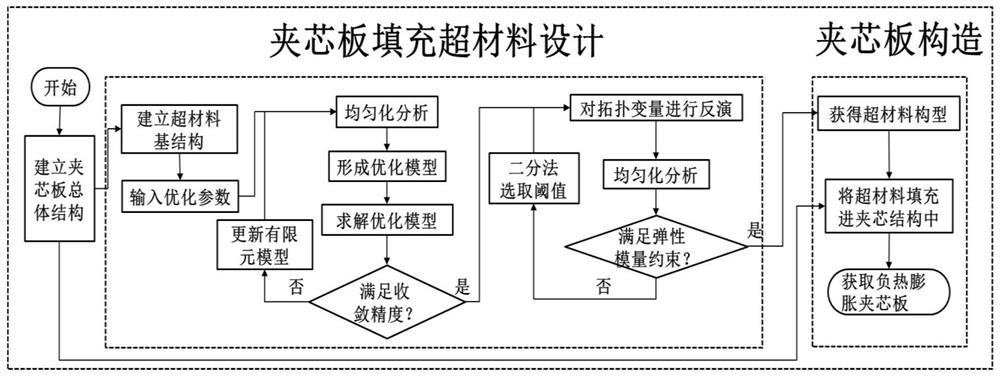

Method used

Image

Examples

Embodiment Construction

[0062] The specific embodiment of the present invention will be described in detail below in conjunction with a topology optimization design example of an adjustable thermal expansion super material.

[0063] In the first step, the overall structure model of the negative heat expansion super material sandwich plate is established. The upper and lower layers are composed of structural steel, and the negative heat expansion hyperbal material is composed of two base material aluminum and structural steel.

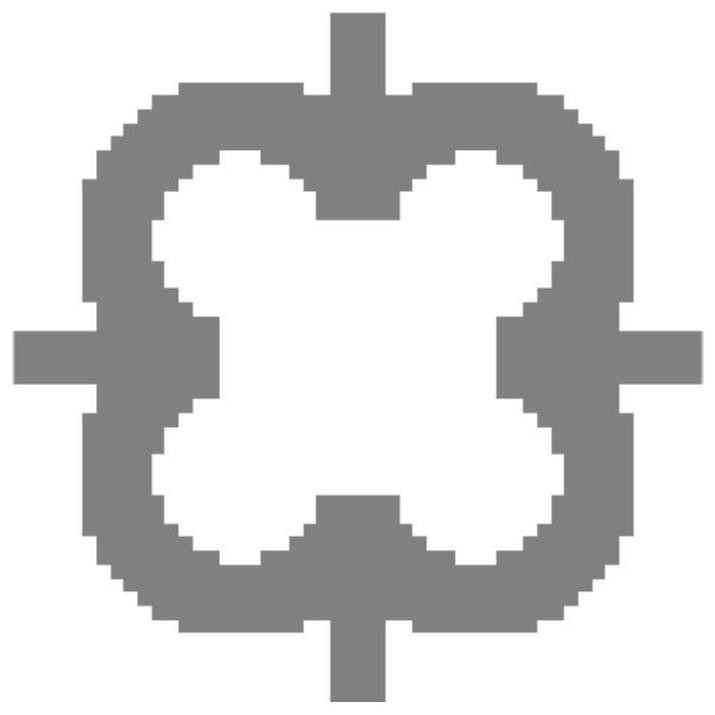

[0064] In the second step, establish a base structure such as figure 2 The finite element model shown in the ultra-material base structure is divided into 50 × 50 units, and the unit is a four-node rectangular unit that becomes 1 × 1.

[0065] In the third step, the definition of material elastic modulus is e (1) = 7, e (2) = 21, Poisson ratio is 3, thermal expansion coefficient α (1) = 5, α (2) = 1, the elastic modulus constraint is 0.3, and the above information is input to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com