A magnetic integrated matrix transformer and isolated dc/dc converter

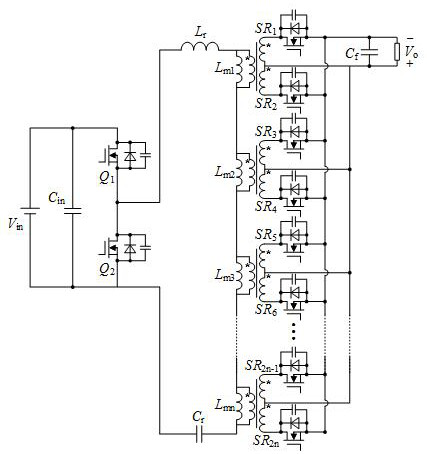

A technology of transformer and magnetic integration, applied in the direction of transformer/inductor core, transformer/inductor cooling, transformer/inductor shell, etc., can solve the problems of lack of versatility and poor flexibility of matrix transformer, so as to improve the transformation efficiency. efficiency, flexibility and versatility, and improved core utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

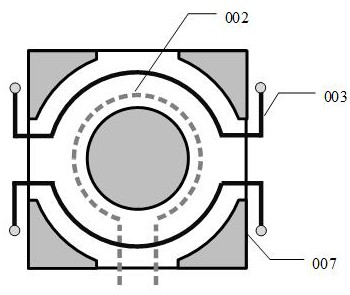

[0071] In this example, the magnetic core adopts a square structure, and the lower part of the square magnetic core quadrilateral column type transformer component refers to Figure 3A , the upper part of the square magnetic core quadrilateral column type transformer assembly refers to 3B. The magnetic core is provided with a base, and the base is provided with a center column and four side columns, and the four side columns are evenly distributed on a square centered on the center column; two secondary side windings are wound on the side columns, and each secondary The side winding is wound on two adjacent side columns, the middle column is used to wind the primary side winding, the magnetic core and the secondary winding wound on the side columns form a transformer assembly; two transformer assemblies with the same structural design are connected to each other After the combination, the center columns of the two are aligned and connected, and the side columns are aligned and...

Embodiment 2

[0074] In this example, the magnetic core adopts a square structure, and the lower square magnetic core quadrilateral column type transformer component refers to Figure 4A , the upper part of the square magnetic core quadrilateral column type transformer assembly refers to Figure 4B . The magnetic core is provided with a base, and the base is provided with a center column and four side columns, and the four side columns are evenly distributed on a square centered on the center column; two secondary windings are wound on the side column, and one secondary winding The winding 003A is wound on three adjacent side columns, another secondary winding 003B is wound on two adjacent side columns, the middle column is used to wind the primary winding 002, and the magnetic core is wound on the side columns The secondary windings of the transformer form a transformer assembly; two transformer assemblies with the same structural design are rotated 180° and combined with each other. Afte...

Embodiment 3

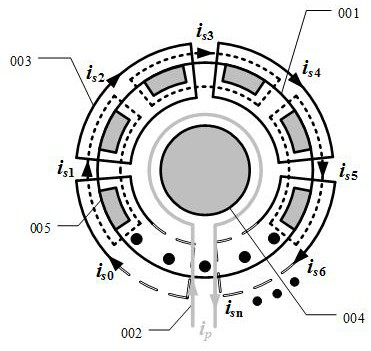

[0078] In this example, the magnetic core adopts a regular hexagonal structure, and the hexagonal magnetic core in the lower part refers to the hexagonal column transformer component Figure 5A , the upper part of the hexagonal magnetic core hexagonal column type transformer assembly refers to Figure 5B . The magnetic core is provided with a base, and the base is provided with a center column and six side columns, and the six side columns are evenly distributed on a regular hexagon centered on the center column; three secondary windings are wound on the six side columns, Each secondary winding is wound on two adjacent side columns, the middle column is used to wind the primary winding, the magnetic core and the secondary winding wound on the side columns form a transformer assembly; two transformers with the same structural design The components are rotated 180° and combined with each other. After the combination, the central columns of the two are aligned and connected, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com