High-current ion implanter and method for controlling ion beam by using high-current ion implanter

一种离子植入、离子束的技术,应用在高电流离子植入器领域,能够解决保持等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

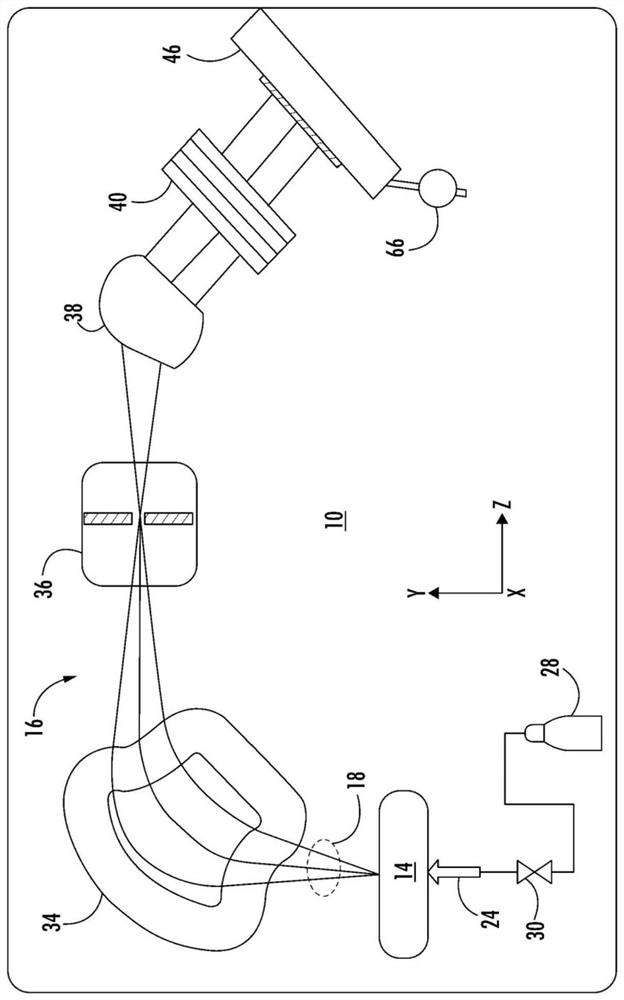

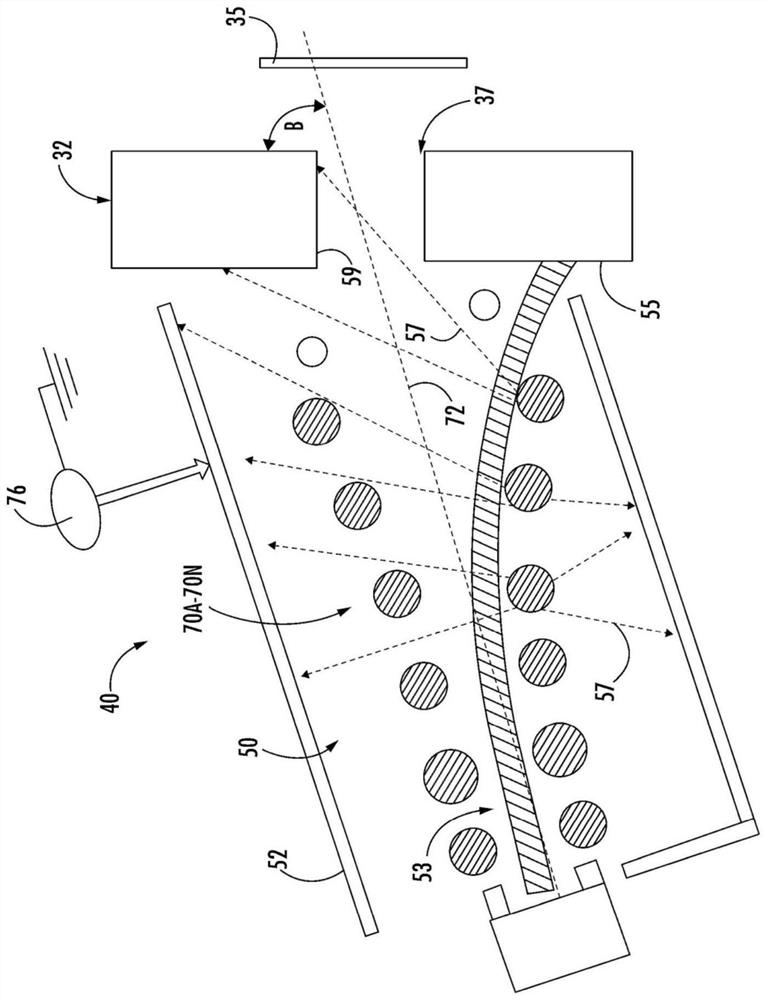

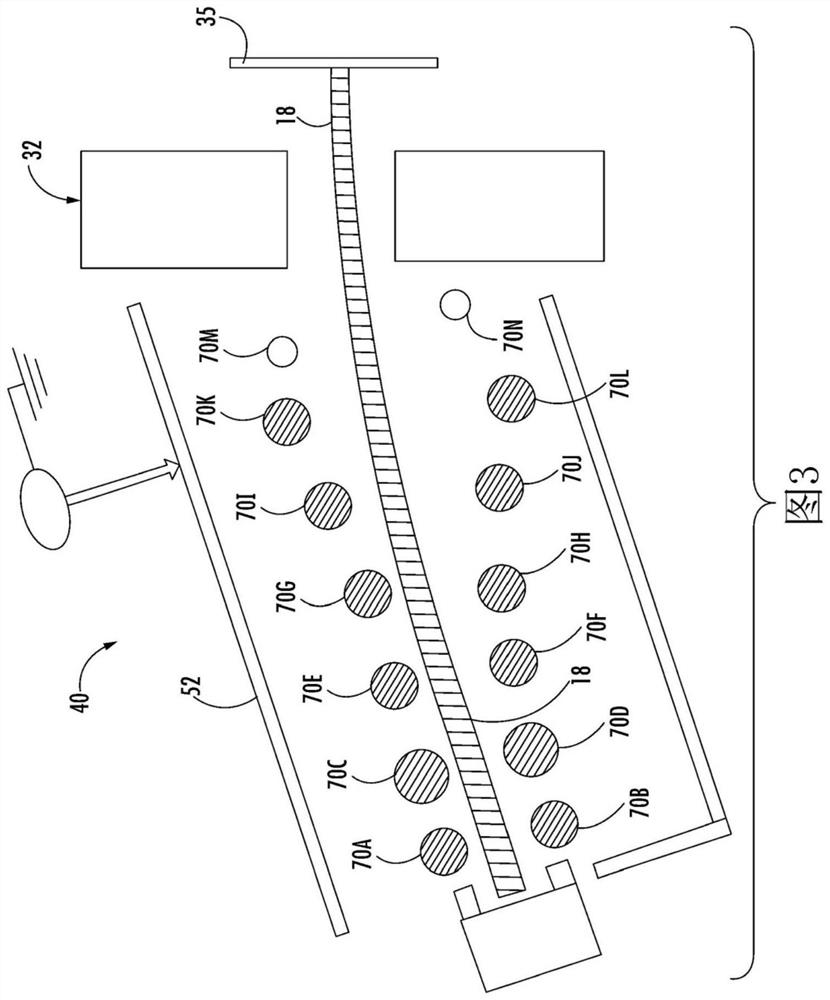

[0016] Ion implantation systems, electrostatic filters or lenses, and methods according to the present disclosure will now be explained more fully hereinafter with reference to the accompanying drawings, in which embodiments of the disclosure are shown. The ion implantation system, electrostatic filter, and method may be implemented in many different forms and are not to be considered limited to the embodiments described herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the systems and methods to those skilled in the art.

[0017] In view of the above-mentioned deficiencies identified by the prior art, provided herein is an ion implantation system that allows high current implanter operation with all the conventional benefits and extended maximum energy to cover a portion of the medium energy implanter operating space , Electrostatic filter and method. An exemplary electrostatic lens for an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com