Self-curing 3D printing bio-ink as well as preparation method and application thereof

A bio-ink and 3D printing technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of poor self-curing properties of α-TCP, complex organic binder preparation process, etc., and achieve excellent apatite deposition ability , regular pore structure and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] First weigh the solids in the following parts by weight: 30 parts of hydroxyapatite powder and 70 parts of tricalcium silicate powder, then put them into a container and use a magnetic stirrer for mechanical mixing to form a uniform solid phase powder; then weigh Add 2g of polyether F127 into 18g of deionized water, and form a polyether F127 solution after stirring continuously; mix the polyether F127 solution with hydroxyapatite / tricalcium silicate composite solid phase powder at a mass ratio of 0.38:1g / g Modulate to obtain 3D printing slurry with flow characteristics; then put the slurry into the barrel of the 3D printer with a needle diameter of 0.6mm, extrude it under 600-800kPa air pressure according to the shape set by the software, and then Curing yields a cylindrical scaffold.

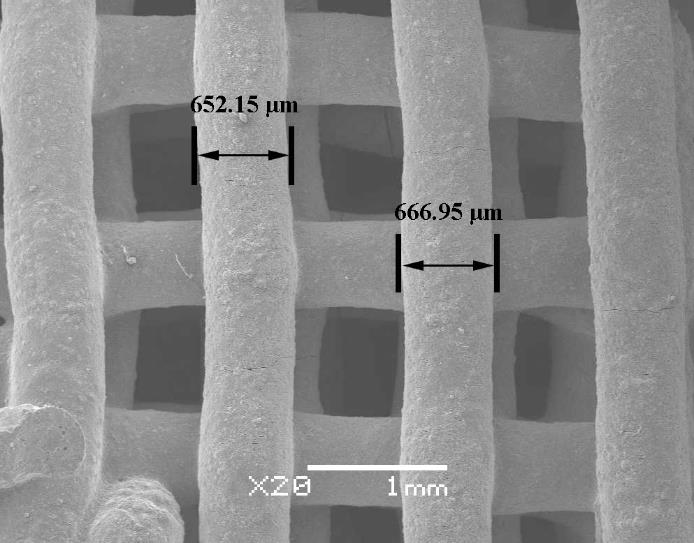

[0029] figure 1 It is a digital photo of the printed stent. It can be seen from the figure that the material can print a three-dimensional through-hole stent with regular shape and pore...

Embodiment 2

[0031] First weigh the solids in the following parts by weight: 40 parts of hydroxyapatite powder and 60 parts of tricalcium silicate powder, then put them into a container and use a magnetic stirrer for mechanical mixing to form a uniform solid phase powder; then weigh Add 2g of polyether F127 into 18g of deionized water, and form a polyether F127 solution after stirring continuously; mix the polyether F127 solution with hydroxyapatite / tricalcium silicate composite solid phase powder at a mass ratio of 0.4:1g / g Modulate to obtain 3D printing slurry with flow characteristics; then put the slurry into the barrel of the 3D printer with a needle diameter of 0.6mm, extrude it under 600-800kPa air pressure according to the shape set by the software, and then Curing yields a cylindrical scaffold.

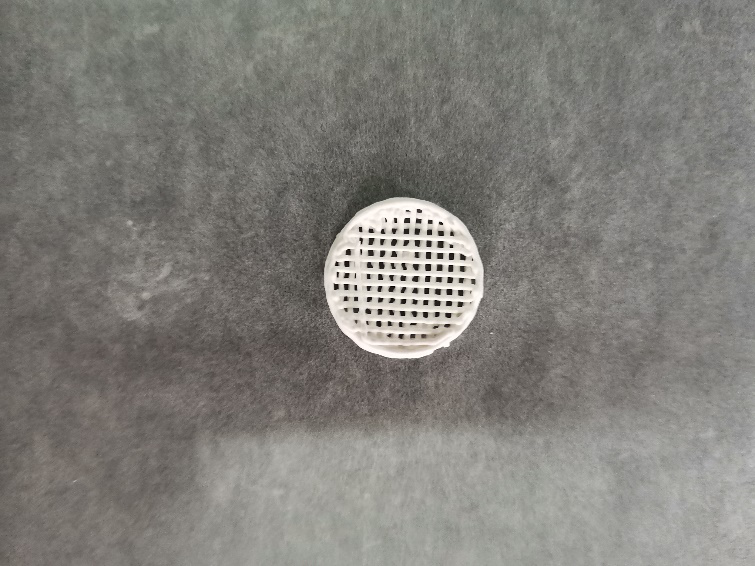

[0032] image 3 It is a digital photo of the printed stent. It can be seen from the figure that the material can print a three-dimensional through-hole stent through a 3D printing device...

Embodiment 3

[0034]First weigh the solids in the following parts by weight: 50 parts of hydroxyapatite powder and 50 parts of tricalcium silicate powder, then put them into a container and use a magnetic stirrer for mechanical mixing to form a uniform solid phase powder; then weigh Add 2g of polyether F127 into 18g of deionized water, and form a polyether F127 solution after stirring continuously; mix the polyether F127 solution with hydroxyapatite / tricalcium silicate composite solid phase powder at a mass ratio of 0.42:1g / g Modulate to obtain 3D printing slurry with flow characteristics; then put the slurry into the barrel of the 3D printer with a needle diameter of 0.6mm, extrude it under 600-800kPa air pressure according to the shape set by the software, and then Curing yields a cylindrical scaffold.

[0035] Figure 4 and Figure 5 It is the surface topography diagram of the prepared scaffold soaked in simulated body fluid. It can be seen from the figure that the surface of the scaff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com