High-performance SmFe12-based permanent magnet powder and preparation method thereof

A permanent magnetic powder, high-performance technology, applied in the direction of magnetic objects, magnetic materials, metal processing equipment, etc., can solve the problems of difficult to guarantee the quality of powder, difficult to prepare high-quality powder, difficult to prepare coercive force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Divide provisioning into (Sm 0.8 Zr 0.2 )(Fe 0.8 co 0.2 ) 10.6 Cu 0.4 Alloys of Ti (adding elements of Zr, Co, Cu and Ti to SmFe 12 alloy) into an induction furnace for high-pressure induction melting for 15s, and then for homogenization annealing at a temperature of 1100°C for 24h. The homogenized annealed alloy ingot is subjected to high-pressure gas atomization pulverization treatment, the pressure of the atomization chamber is 0.3MPa, and the gas in the chamber is high-purity N 2 , the spray casting pressure is 0.5MPa, the atomizing gas is high-purity Ar, and the atomizing gas pressure is 2.0MPa, and high-performance SmFe 12 base permanent magnet powder.

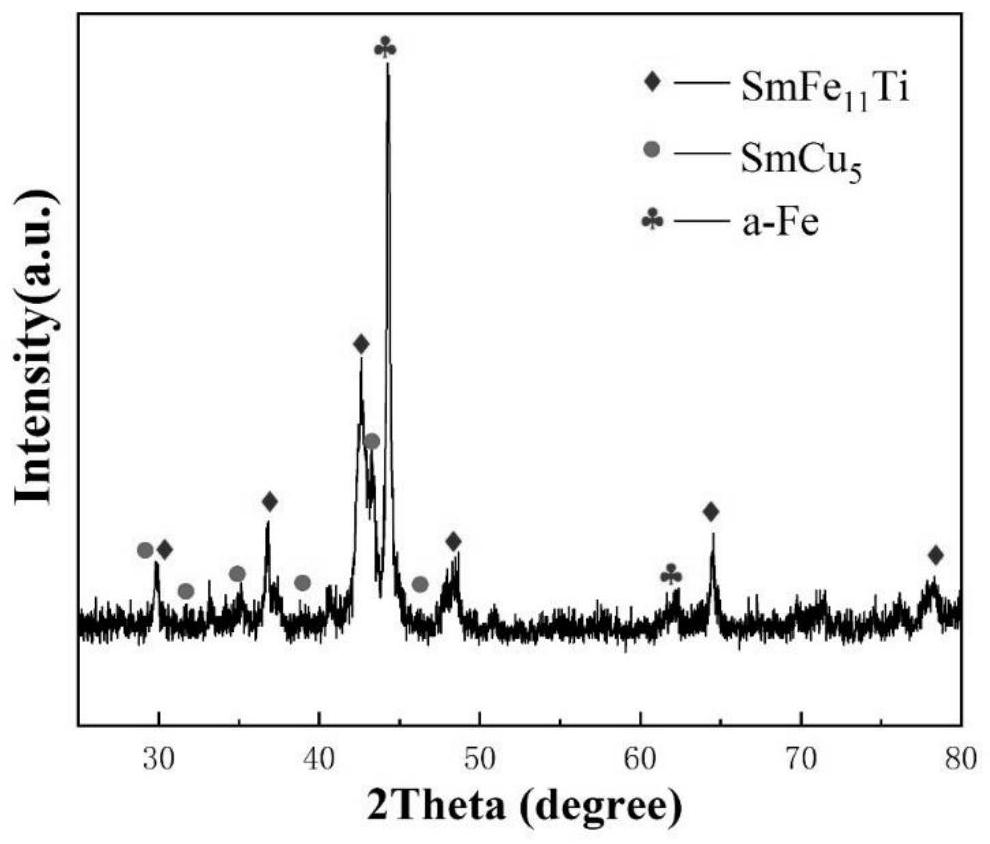

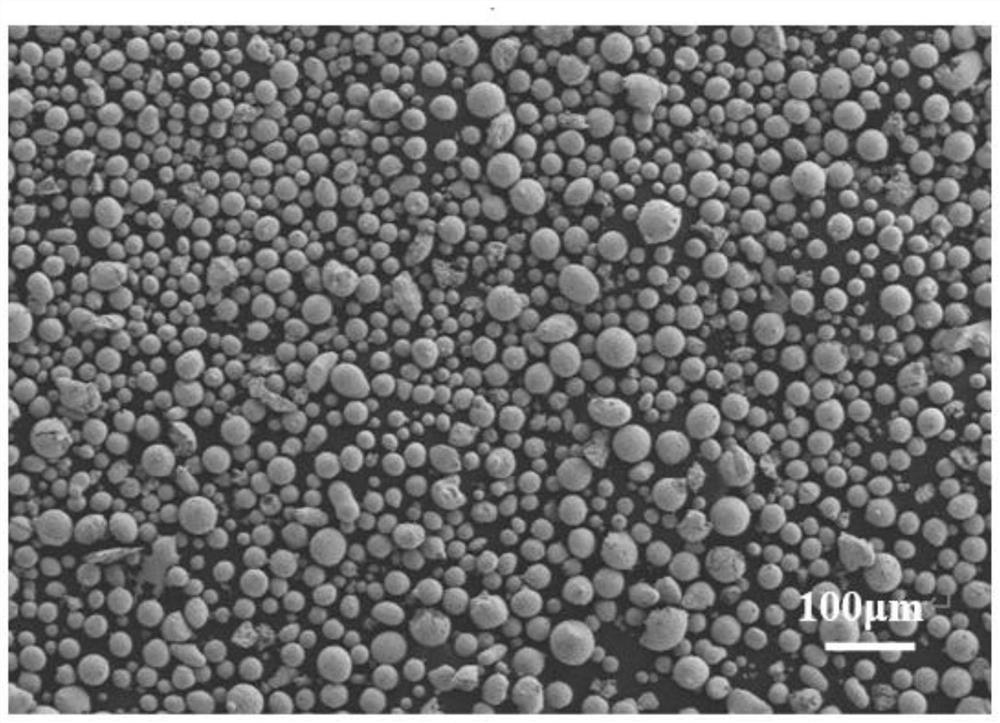

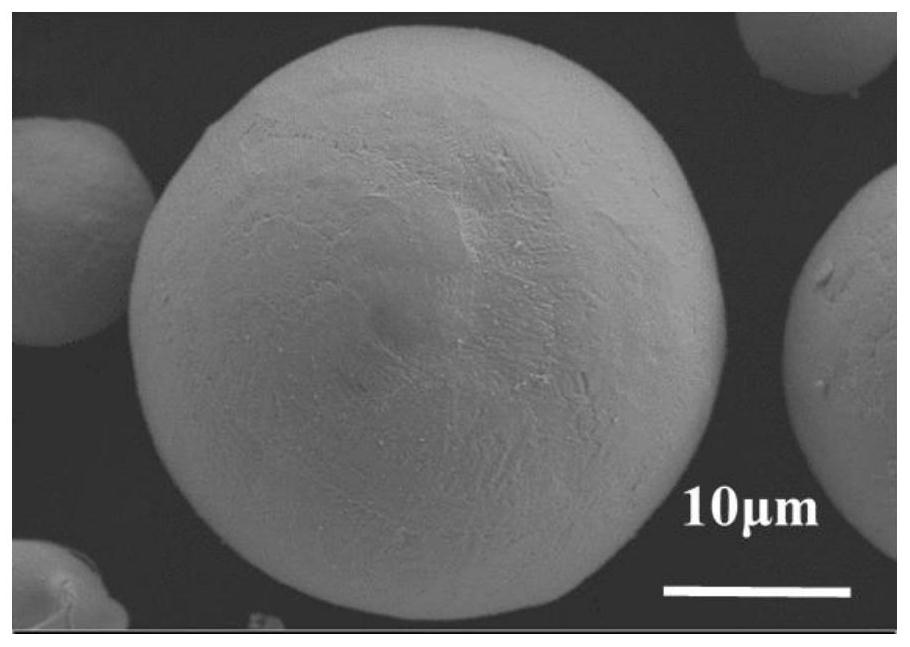

[0034] The high-performance SmFe of this embodiment 12 The XRD spectrum of the base permanent magnet powder is shown in figure 1 , the morphology of the atomized powder is shown in figure 2 , the surface topography of a single atomized powder is shown in image 3 , microscopic BSED diagram see Figure...

Embodiment 2

[0036] Divide provisioning into (Sm 0.8 Zr 0.2 )(Fe 0.8 co 0.2 ) 10.5 Cu 0.5 Alloys of Ti (adding elements of Zr, Co, Cu and Ti to SmFe 12 alloy) into an induction furnace for high-pressure induction melting for 15s, and then for homogenization annealing at a temperature of 1100°C for 24h. The homogenized annealed alloy ingot is subjected to high-pressure gas atomization pulverization treatment, the pressure of the atomization chamber is 0.5MPa, and the gas in the chamber is high-purity N 2 , the spray casting pressure is 0.7MPa, the atomizing gas is high-purity Ar, and the atomizing gas pressure is 2.5MPa, and high-performance SmFe 12 base permanent magnet powder.

Embodiment 3

[0038] Divide provisioning into (Sm 0.7 Zr 0.3 )(Fe 0.8 co 0.2 ) 10.6 Cu 0.4 Alloys of Ti (adding elements of Zr, Co, Cu and Ti to SmFe 12 alloy) into an induction furnace for high-pressure induction melting for 15s, and then for homogenization annealing at a temperature of 1100°C for 24h. The homogenized annealed alloy ingot is subjected to high-pressure gas atomization pulverization treatment, the pressure of the atomization chamber is 0.7MPa, and the gas in the chamber is high-purity N 2 , the spray casting pressure is 0.9MPa, the atomizing gas is high-purity Ar, and the atomizing gas pressure is 2.8MPa, and high-performance SmFe 12 base permanent magnet powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com