Blade type design method of gear workpiece end face continuous equidistant chamfering cutting tool

A technology of cutting tools and design methods, which is applied in the direction of gear tooth manufacturing tools, manufacturing tools, and components with teeth, etc., can solve the problems of cutting tool cutting edge design methods that have not yet been seen, difficult product update iterations, poor precision, etc. Achieve the effects of cutting state optimization, good numerical stability, and calculation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

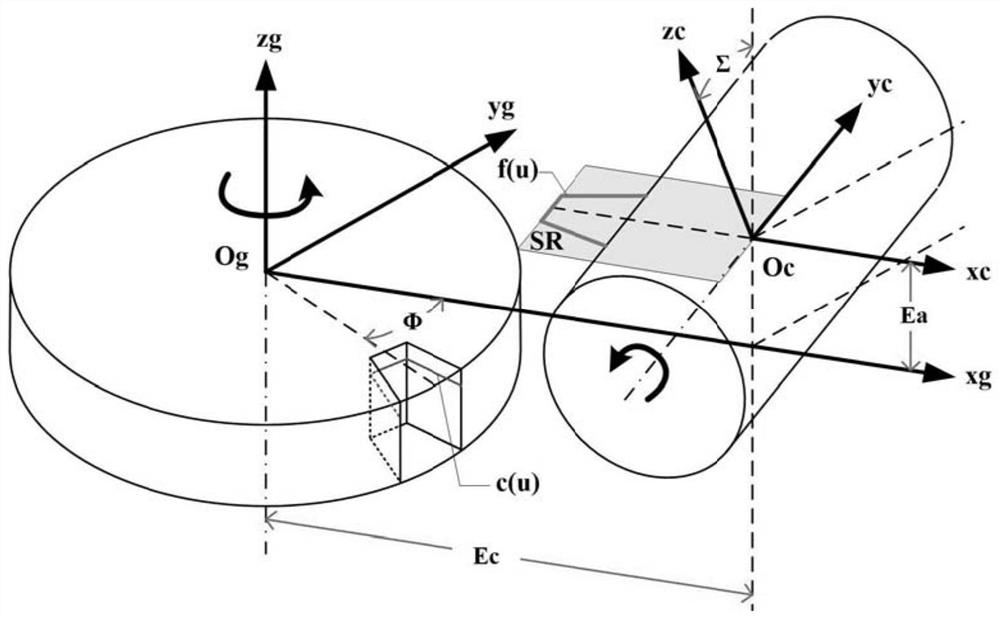

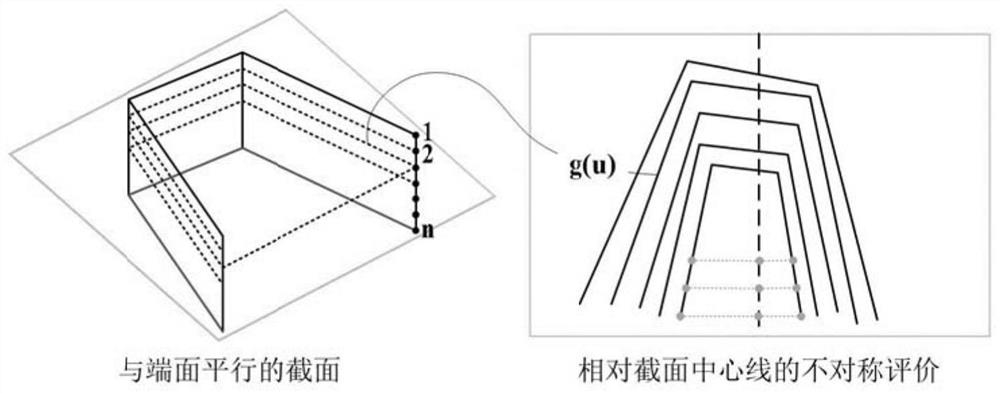

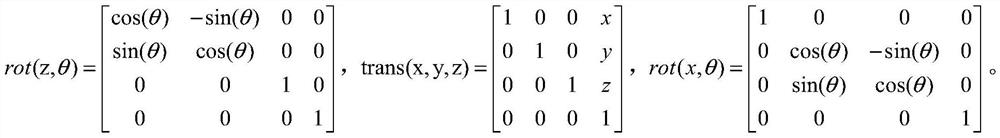

[0078] A method for designing a blade shape of a cutting tool for continuous equidistant chamfering of the end face of a gear workpiece, comprising the following steps,

[0079] Step 1, prepare the gear workpiece parameters required for cutting tool cutting edge calculation, including structural parameters and end face profile parameters;

[0080] The structural parameters of the gear workpiece include: the number of teeth zg=40, the helix angle βg=0, and parameters related to the tooth shape of the end face, such as the modulus of the involute gear 2mm, the pressure angle 20°, etc.;

[0081] The structural parameters of the gear end face chamfer include the depth of the end face profile chamfer along the gear axis h = 0.5mm;

[0082] Step 2, according to the traditional hob design experience, design the structural parameters of the cutting tool;

[0083] The cutting tooth structure parameters of the cutting tool include: number of teeth zc=8, right-handed rotation, helix ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com