High-viscosity composite gummed paper cutting machine and method

A compound adhesive, high-viscosity technology, used in cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc. Advanced problems, to achieve the effect of improving cutting strength, good cutting effect, and improving working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

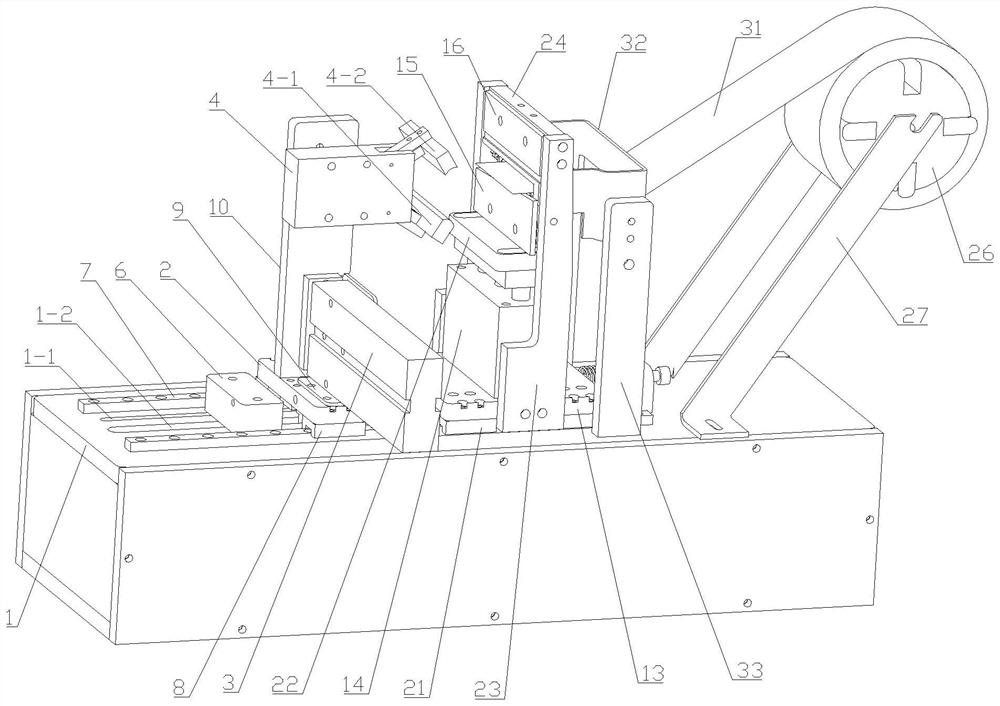

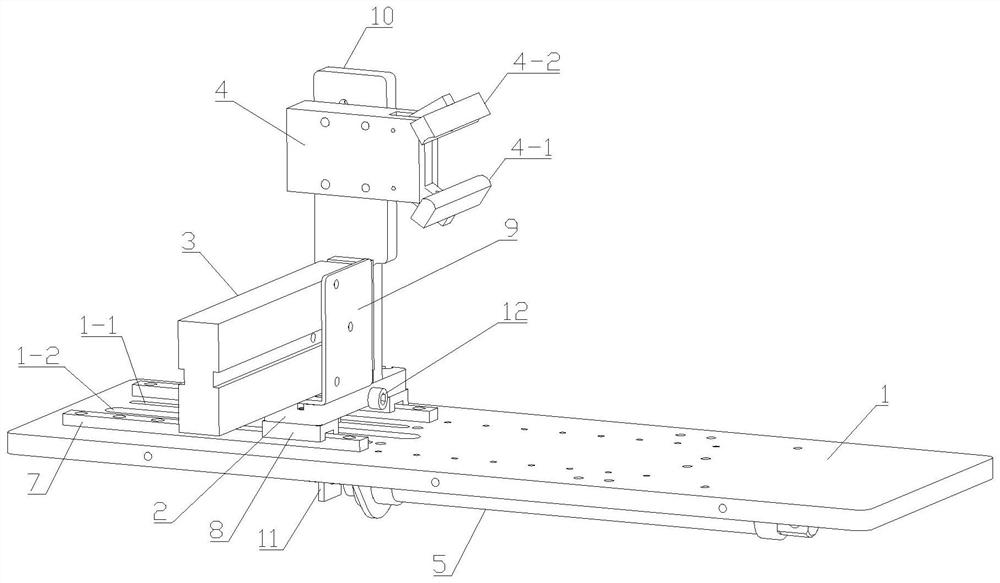

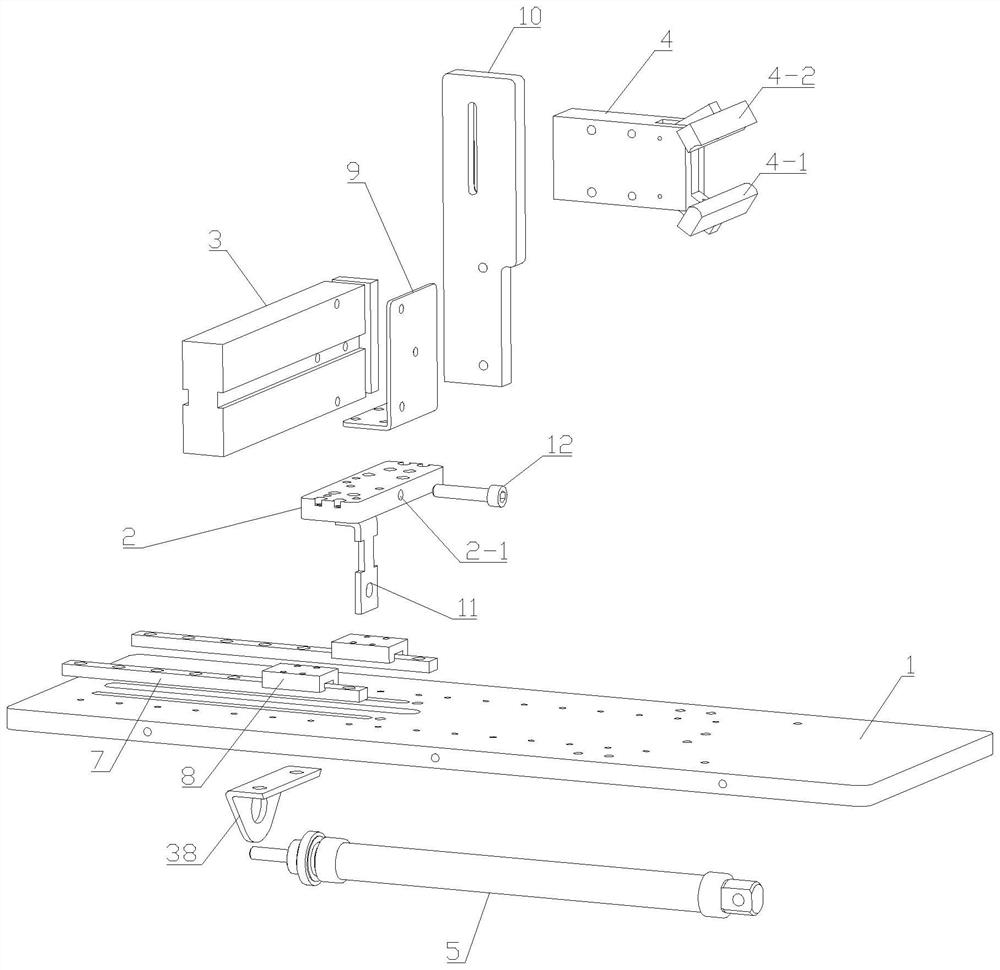

[0064] Such as Figure 1 to Figure 6 A high-viscosity compound adhesive tape cutting machine shown includes a base and an adhesive tape pulling mechanism, an adhesive tape cutting mechanism and an adhesive tape feeding mechanism installed on the base sequentially along the length direction of the base, and the base is hollow base;

[0065] The adhesive tape pulling mechanism includes a pull-out slide plate 2 slidably installed on the workbench 1 of the base, a push-out cylinder 3 arranged on the pull-out slide plate 2 and a finger cylinder 4 installed on the piston rod end of the push-out cylinder 3, the The base is provided with a pulling cylinder 5 for driving the pulling slide 2 to move along the length direction of the base. The lower clamping part 4-1 of the finger cylinder 4 is provided with an outwardly convex arc clamping surface, and the finger The upper clamping part 4-2 of the cylinder 4 is provided with a concave arc clamping surface matched with the convex arc cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com