Solid waste-based super-retarded cement as well as preparation method and application thereof

An ultra-retarding and cement technology, applied in the field of cement materials, can solve the problems of not being able to meet the time requirements of three-layer continuous paving and long-distance transportation of mixtures, and achieve the goals of improving market competitiveness, delaying setting time, and increasing SO3 content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

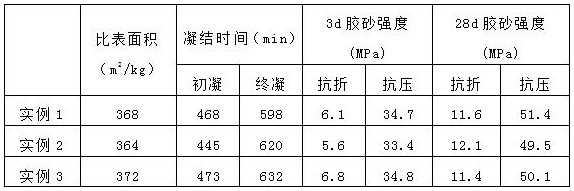

Embodiment 1

[0028] A kind of solid waste-based super-retarded cement for road base and its preparation method, comprising the following steps:

[0029] 1. According to the quality, take 64 parts of limestone, 18 parts of sugar residue, 2 parts of non-ferrous metal ash, 4 parts of dried sludge, 2 parts of polluted soil, 10 parts of red shale and other raw materials, which are crushed, pre-homogenized, and mixed in proportion Then enter the raw meal mill for grinding to obtain cement raw meal. The raw materials are sent to the shaft kiln and rotary kiln for calcining respectively to obtain molten materials, which are cooled by a grate cooler to obtain two kinds of cement clinker, which are then configured and homogenized according to the mass ratio of 1:1 to obtain usable cement clinker. material. After the road base is further cooled with solid waste-based ultra-retarding cement clinker, 60 parts of clinker, 14 parts of fly ash, 10 parts of slag powder, 2 parts of dihydrate gypsum, 4 part...

Embodiment 2

[0032] A kind of solid waste base ultra-retarded cement for road base and preparation method thereof, comprises the following steps:

[0033] According to the quality, 67 parts of limestone, 14 parts of sugar residue, 4 parts of non-ferrous metal ash, 2 parts of dried sludge, 4 parts of polluted soil, 9 parts of red shale and other raw materials are crushed, pre-homogenized, and mixed in proportion before entering The cement raw meal is obtained by grinding in the raw meal mill. The raw materials are sent to the shaft kiln and rotary kiln for calcining respectively to obtain molten materials, which are cooled by a grate cooler to obtain two kinds of cement clinker, which are then configured and homogenized according to the mass ratio of 1:1 to obtain usable cement clinker. material. The road base layer is piled with solid waste-based ultra-retarded cement clinker, and after further cooling, 68 parts of clinker, 10 parts of fly ash, 8 parts of slag powder, 3 parts of dihydrate...

Embodiment 3

[0036] A kind of solid waste base ultra-retarded cement for road base and preparation method thereof, comprises the following steps:

[0037]According to the quality, 64 parts of limestone, 16 parts of sugar residue, 3 parts of non-ferrous metal ash, 3 parts of dried sludge, 4 parts of polluted soil, 10 parts of red shale and other raw materials are crushed, pre-homogenized, and mixed in proportion before entering The cement raw meal is obtained by grinding in the raw meal mill. The raw materials are sent to the shaft kiln and rotary kiln for calcining respectively to obtain molten materials, which are cooled by a grate cooler to obtain two kinds of cement clinker, which are then configured and homogenized according to the mass ratio of 1:1 to obtain usable cement clinker. material. The road base layer is piled with solid waste-based ultra-retarded cement clinker, and after further cooling, 64 parts of clinker, 12 parts of fly ash, 9 parts of slag powder, 2 parts of dihydrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com