Longitudinal variable-thickness steel plate for upper deck of crude oil cargo oil tank and production method of longitudinal variable-thickness steel plate

A longitudinally variable thickness, cargo oil tank technology, applied in temperature control, manufacturing tools, metal rolling, etc., can solve the problems of steel plate strength, low toughness, high production cost, can not meet the requirements of use, etc., and achieve excellent mechanical properties And the effect of good uniformity of corrosion resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

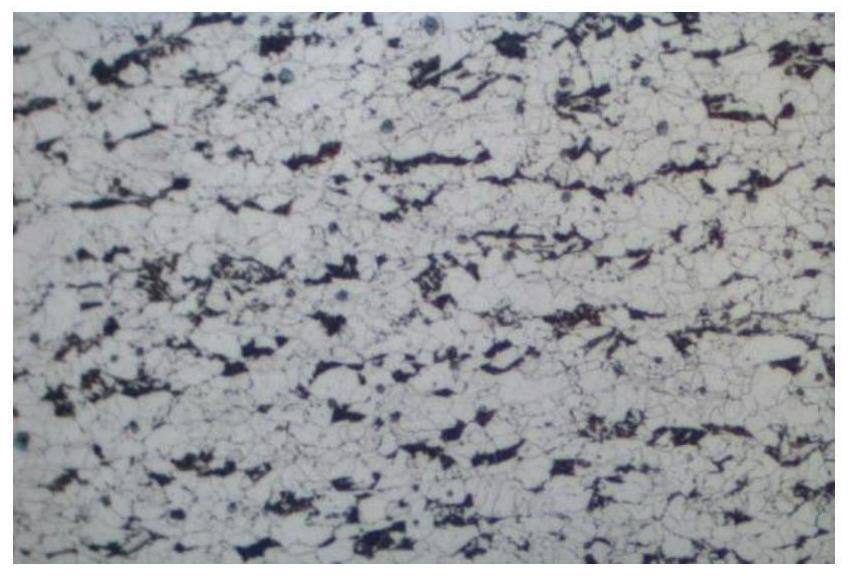

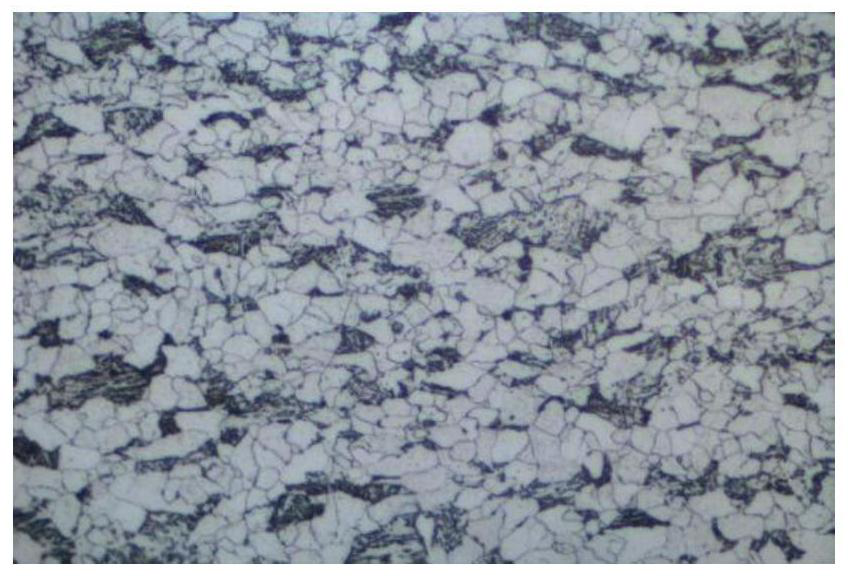

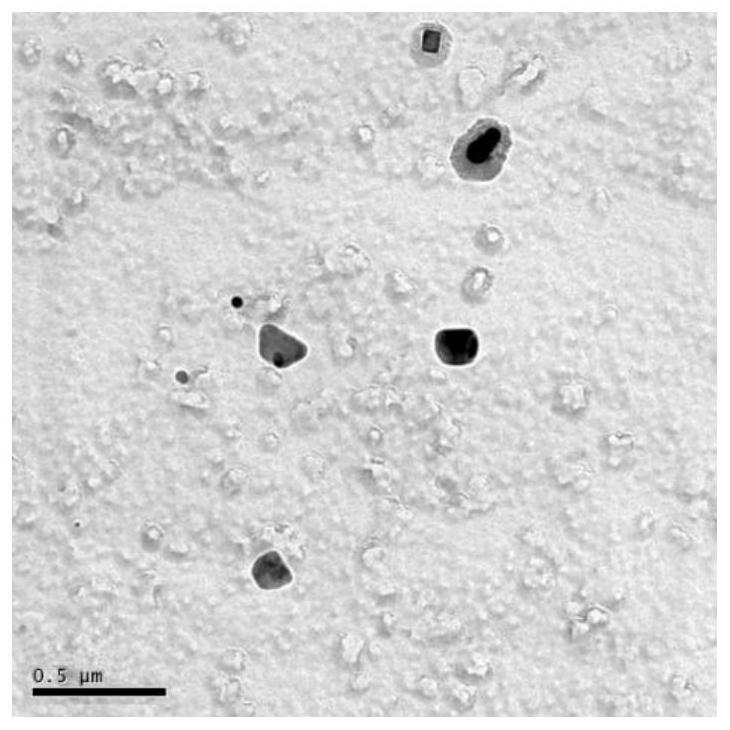

Image

Examples

Embodiment Construction

[0047] The specific embodiment of the present invention is further described below:

[0048] Production method of longitudinally variable-thickness steel plates for upper decks of crude oil cargo tanks,

[0049] 1) Smelting is carried out according to the chemical composition designed for the steel plate, and the chemical composition is shown in Table 1.

[0050] Table 1: Chemical Composition (wt%) of Example Steel

[0051]

[0052]

[0053] 2) Continuous casting-heating-rolling-cooling of the obtained molten steel to obtain a longitudinally variable-thickness steel plate. The heating process is shown in Table 2, the rolling process is shown in Table 3, and the cooling process is shown in Table 4.

[0054] Table 2: Example heating process

[0055] Numbering Superheat / ℃ Slow cooling time / h Heating temperature / ℃ Heating rate / ℃ / min Holding time / min 1 27 38 1125 13 60 2 29 42 1115 14 100 3 32 50 1145 16 150 4 33 54 1175...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com