Preparation method of corrosion resistant magnesium/zinc composite board

A composite plate, corrosion-resistant technology, applied in temperature control, metal rolling, etc., to achieve energy saving, good mechanical properties and corrosion resistance, and low processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

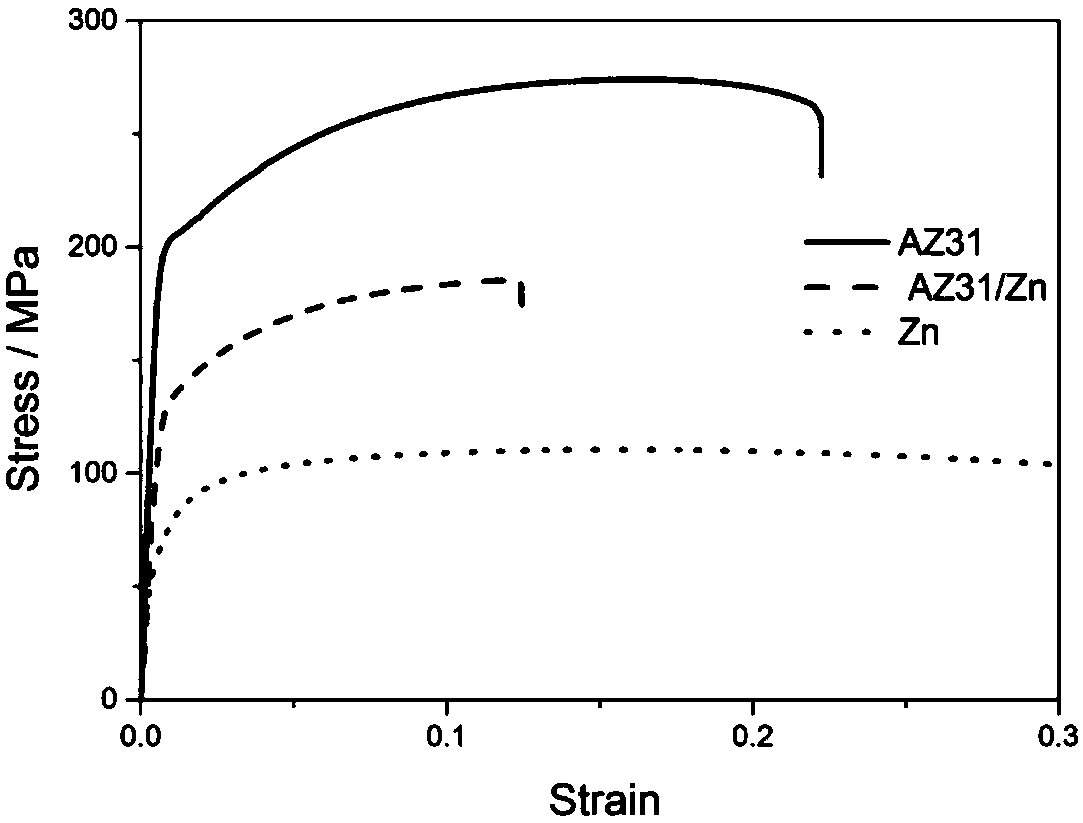

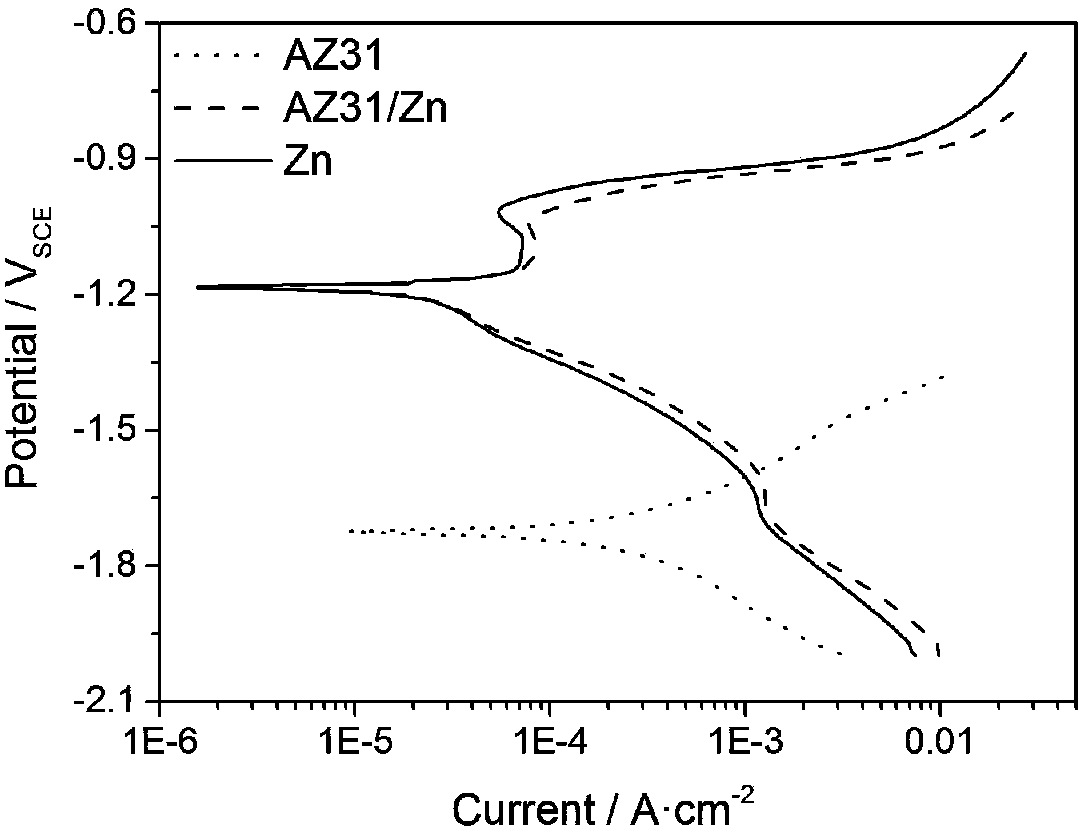

[0028] Example 1: AZ31 / pure zinc composite sheet

[0029] (1) The 0.5mm thick pure zinc plate and the 1mm thick AZ31 plate are machined into a rectangular sample of 60mm×150mm, and placed in a medium temperature furnace for annealing treatment. The annealing temperature of the pure zinc plate is 150°C, and the time is The annealing temperature of the AZ31 plate is 300°C, the time is 60 minutes, and the plate is taken out and cooled in air.

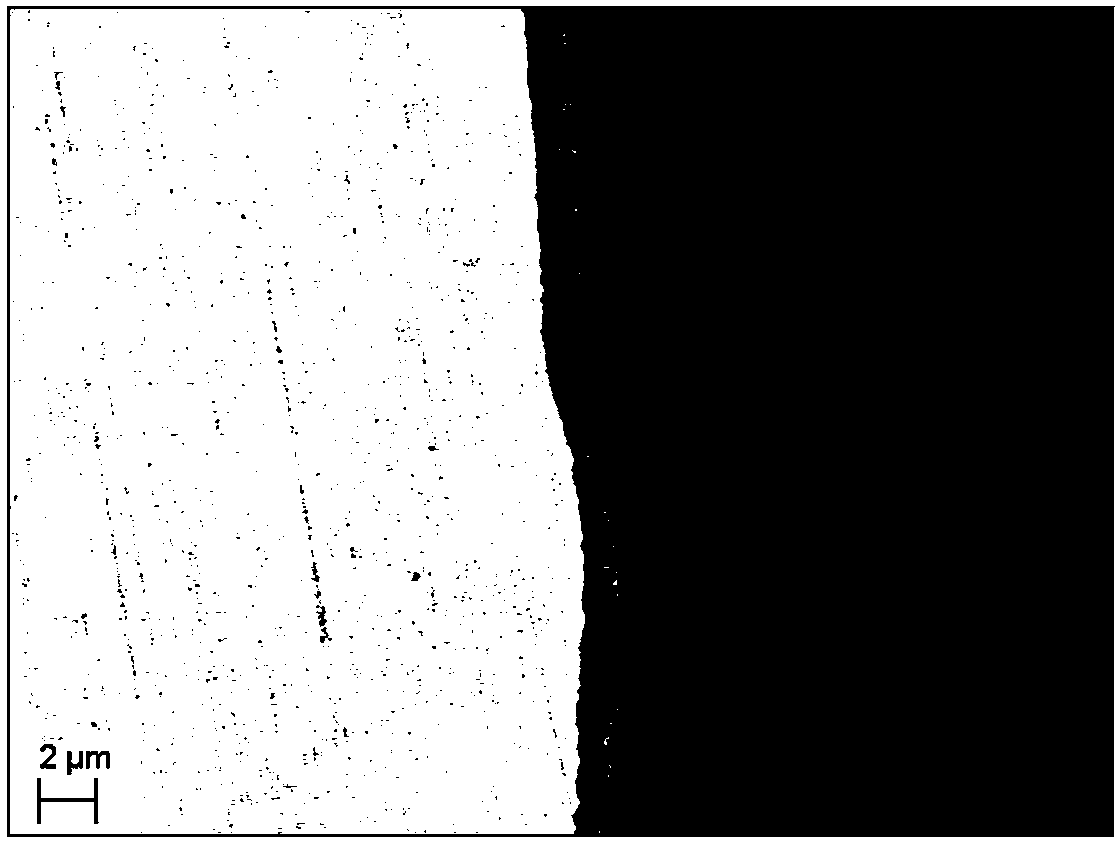

[0030] (2) Grind one side of the pure zinc plate and both sides of the AZ31 plate. The sandpaper used is 60# sandpaper, and the grinding direction is always along the length direction. The surface oxide layer is removed, and chemically cleaned with absolute ethanol, and dried with cold air.

[0031] (3) Place the pure zinc plate on both sides of the AZ31 plate and fix them together with iron wires to make a composite billet.

[0032] (4) Put the composite billet into a medium-temperature furnace for preheating, the preheating temperature ...

Embodiment 2

[0036] Embodiment 2: MgZnCa / pure zinc composite plate

[0037] (1) Machine a 0.5mm thick pure zinc plate and a 1mm thick MgZnCa (Zn=2wt.%, Ca=0.2wt.%) plate into a rectangular sample of 60mm×80mm, and put them into a medium temperature furnace Perform annealing treatment. The annealing temperature of the Zn plate is 150° C. for 30 minutes, the annealing temperature of the MgZnCa plate is 350° C. and the time is 4 hours. The plates are taken out and cooled in air.

[0038] (2) Grind one side of the pure zinc plate and both sides of the MgZnCa plate. The sandpaper used is 60# sandpaper, and the grinding direction is always along the length direction. The surface oxide layer is removed, and the chemical cleaning is carried out with absolute ethanol, and the cold air is blown dry.

[0039] (3) Place the pure zinc plate on both sides of the MgZnCa plate and fix them together with iron wires to make a composite blank.

[0040] (4) Put the composite billet into a medium-temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com