Water-based organic silicon high-temperature-resistant coating and preparation method thereof

A high-temperature-resistant coating and high-temperature-resistant filler technology, which is applied in anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve problems such as limited high-temperature resistance, long-term use, and failure to meet environmental protection and market requirements, and achieve low VOC content. Excellent performance and anti-corrosion performance, and the effect of promoting room temperature curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

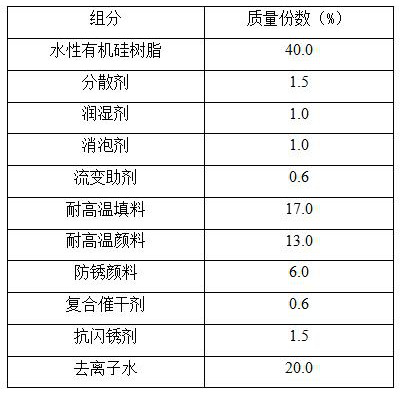

[0061] A kind of waterborne organosilicon high temperature resistant coating, its formula is as table 1;

[0062] Table 1: Coating formulation of Example 1

[0063]

[0064] Among them, the water-based silicone resin is made by mixing DOWSIL 8016 and 3141 at a mass ratio of 7:1.

[0065] The high temperature resistant filler is composed of modified silica powder and wet-process sericite powder in a mass ratio of 4:1.

[0066] The preparation method comprises the following steps:

[0067] (1) Weigh each component in proportion;

[0068](2) Add 1.5 parts of dispersant BYK-190, 1.0 part of wetting agent TEGO 4100, 1.0 part of defoamer TEGO 901W, and 0.6 part of rheological additive BENTONE LT into deionized water in sequence, and stir evenly at low speed (400r / min) After that, disperse at high speed (1200r / min) for 20min;

[0069] (3) Add 40 parts of water-based silicone resin and disperse at high speed (1200r / min) for 10 minutes;

[0070] (4) Slowly add 0.6 parts of drie...

Embodiment 2-3

[0072] The coating formula of embodiment 2-3 sees table 2 and table 3 respectively, and preparation method is with embodiment 1,

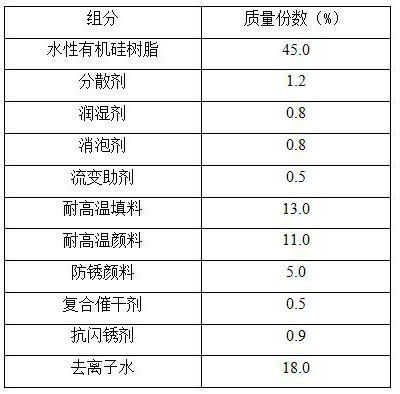

[0073] Table 2: Coating formulation of Example 2

[0074]

[0075] Among them, the water-based silicone resin is made by mixing DOWSIL 8016 and 3141 at a mass ratio of 8:1.

[0076] The high temperature resistant filler is composed of modified silica powder and wet-process sericite powder in a mass ratio of 5:1.

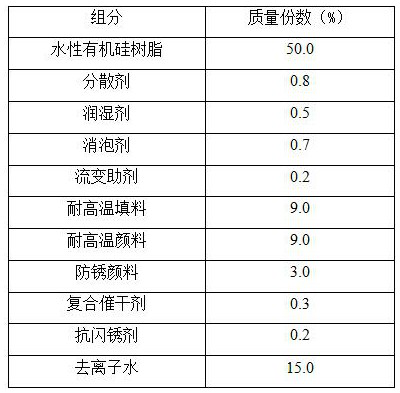

[0077] Table 3: Coating formula of embodiment 3

[0078]

[0079] Among them, the water-based silicone resin is made by mixing DOWSIL 8016 and 3141 at a mass ratio of 9:1.

[0080] The high temperature resistant filler is composed of modified silicon micropowder and wet-process sericite powder in a mass ratio of 6:1.

[0081] See Table 4 for the main performance test results of the water-based silicone high-temperature resistant coating obtained in Examples 1-3 and the commercially available German Wacker SILRES MP 50E water-base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com