Self-repairing polypropylene skin material for surface of building template and preparation and use methods

A technology of building formwork and polypropylene, which is applied in the field of construction building formwork, can solve the problems of corrosion resistance and acid resistance, poor friction resistance, damage to formwork surface quality, and low reuse rate, achieve good corrosion resistance and water resistance, and realize green Sustainability and high reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

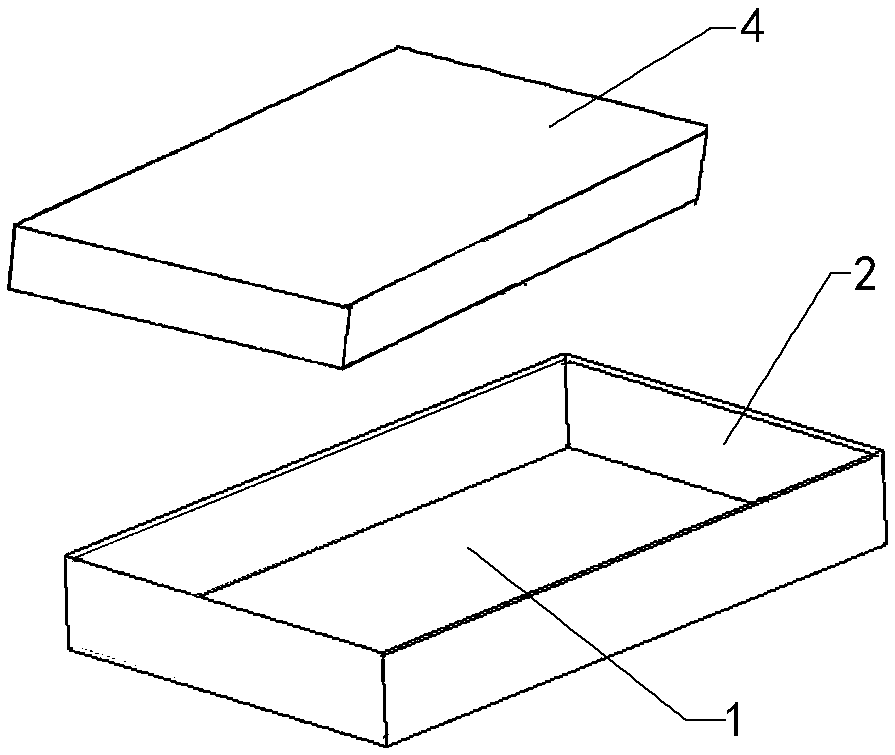

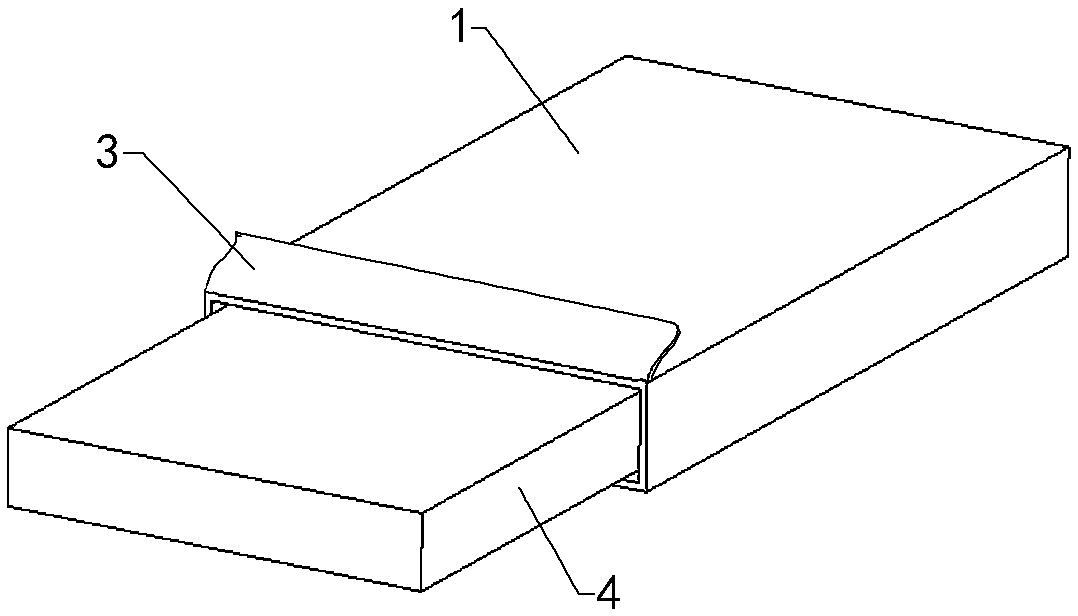

[0038] The thickness of the self-repairing polypropylene skin 1 used on the surface of the building formwork of the present invention is only 0.5-2 mm, and it is paved on the surface of the building formwork 4 and arranged in contact with the surface of the building formwork 4 .

[0039] The skin 1 of the present invention can be fixedly or not fixedly connected with the building formwork 4, without affecting the pouring construction of the concrete in the formwork; its specific use method includes the following steps:

[0040] Step A, cleaning the surface of the building formwork 4, erasing impurities on the surface, avoiding damage to the skin 1 caused by raised and sharp objects; the skin 1 prepared by the present invention is suitable for building formwork 4 of any material type;

[0041] Step B, setting the skin 1 fit cover on the outer surface of the building template 4;

[0042] According to the structure of the skin 1, the installation of the skin 1 can be divided into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com