Connection structure of PVC-FRP pipe concrete column and concrete shear wall and installation method of connection structure

A PVC-FRP, concrete shear wall technology, applied in the direction of columns, walls, pier columns, etc., can solve the problems of destroying PVC pipes, speeding up construction progress, stress concentration, etc., achieve good integrity, improve bearing capacity, and bearing capacity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

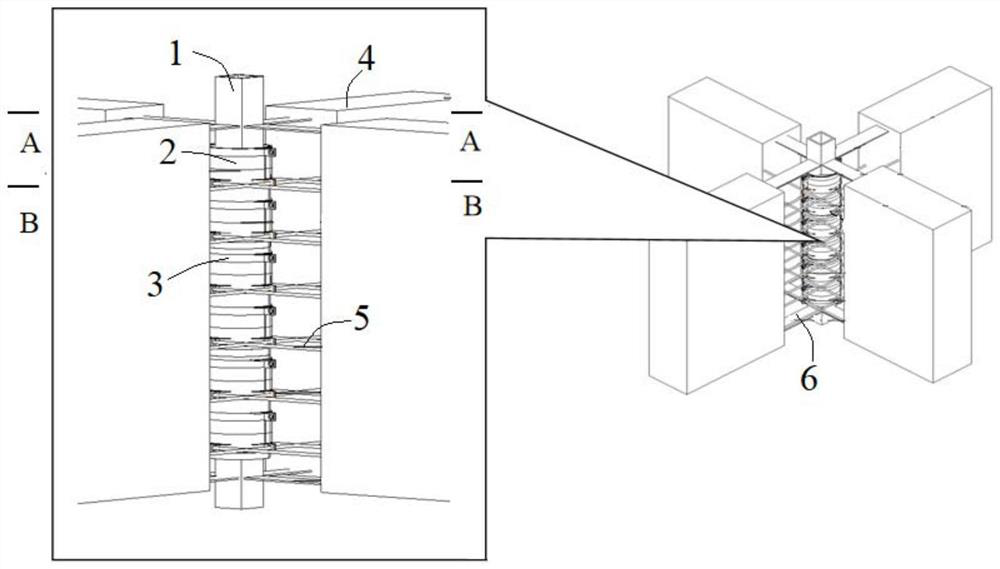

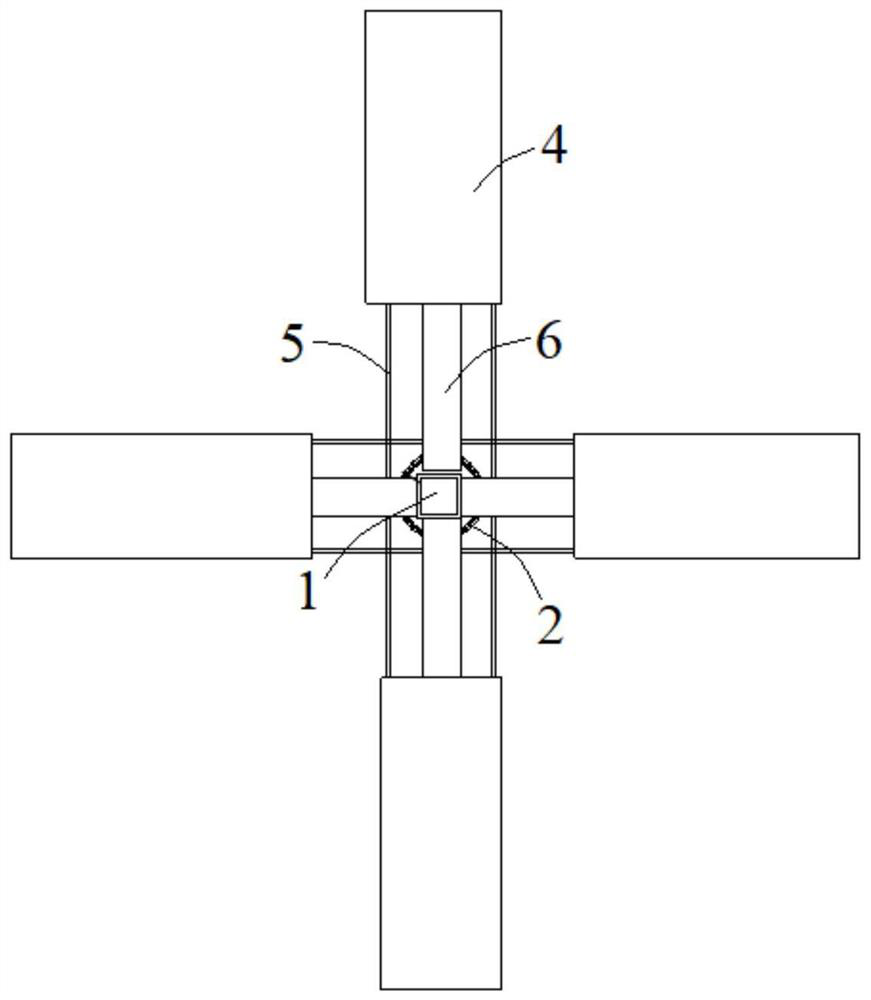

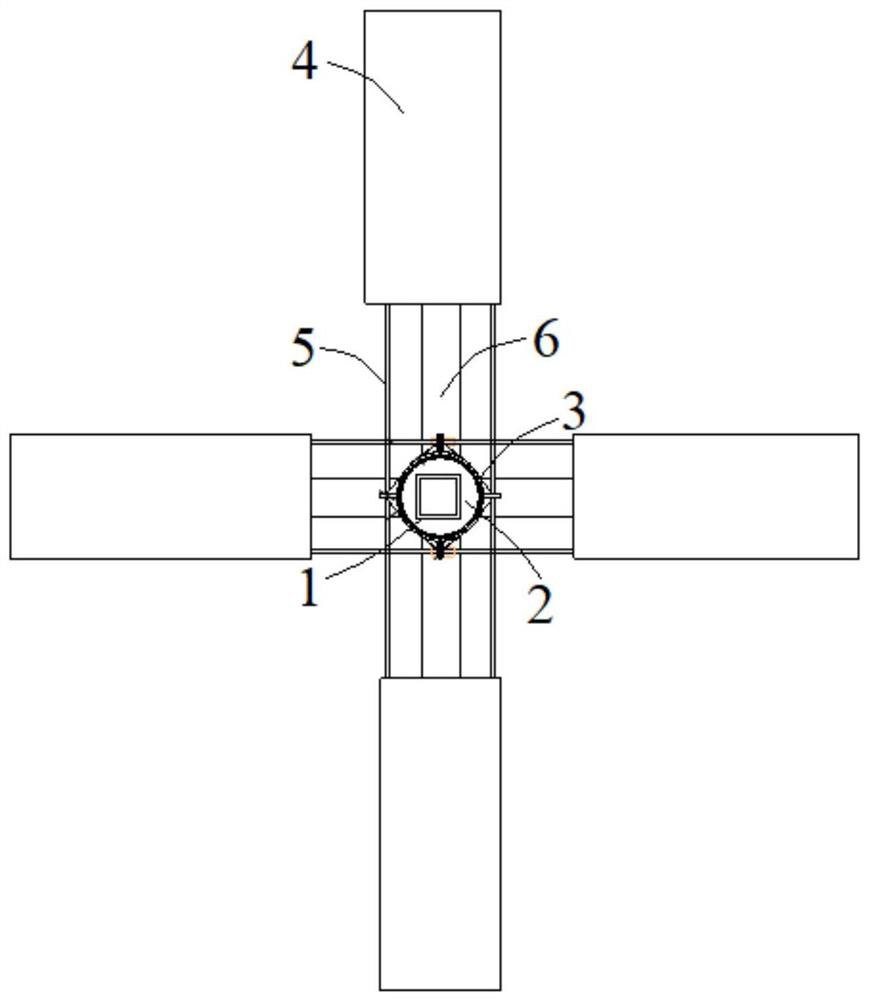

[0043] combine Figure 1-Figure 3 , a connection structure between a PVC-FRP pipe reinforced concrete column and a reinforced concrete shear wall in this embodiment, comprising a concrete column 2 and a shear wall 4 connected around the concrete column 2; the outer periphery of the concrete column 2 is wrapped more A rigid collar structure 3 constrains and strengthens the concrete column 2 . The plurality of collar structures 3 are arranged at intervals on the outer edge of the concrete column 2 and are closely attached to the concrete column 2 . In this embodiment, six collar structures 3 are provided in total. Both the upper and lower ends of the concrete column 2 are embedded with core steel pipes 1 , and one end of each core steel pipe 1 protrudes from the concrete column 2 .

[0044] combine Figure 5-Figure 7, the collar structure 3 of this embodiment includes a lower collar 31 and an upper collar 34, the two are fixedly connected by threads to form a collar structure...

Embodiment 2

[0059] The structure of this embodiment is basically the same as that of the embodiment, except that the plurality of ring structures 3 are fixedly connected to each other to form a whole, which is set on the outer edge of the concrete column 2 and is closely connected to the concrete column 2. fit. Meanwhile, specifically in this embodiment, the FRP type of the PVC-FRP pipe 21 is GFRP; the cross section of the prefabricated concrete column 2 is circular. The shear wall 4 is "L-shaped". The poured concrete 22 is high-strength concrete. The lower collar 31, the upper collar 34, the core steel pipe 1 and the connecting plate 6 are Q3455 steel. The distance between horizontally distributed ribs 5 is 150mm, and its diameter is less than or equal to the inner diameter of the hollow part of the hollow bolt. The cross section of the core steel pipe 1 is circular; the connecting plate 6 and the core steel pipe 1 are connected by bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com