Asphalt mixture flue gas detection/collection integrated device and test method

A technology for asphalt mixture and flue gas detection, which is applied in the direction of sampling devices, etc., can solve the problems of filter blockage, heavy labor, lack of asphalt mixture, etc., and achieve the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

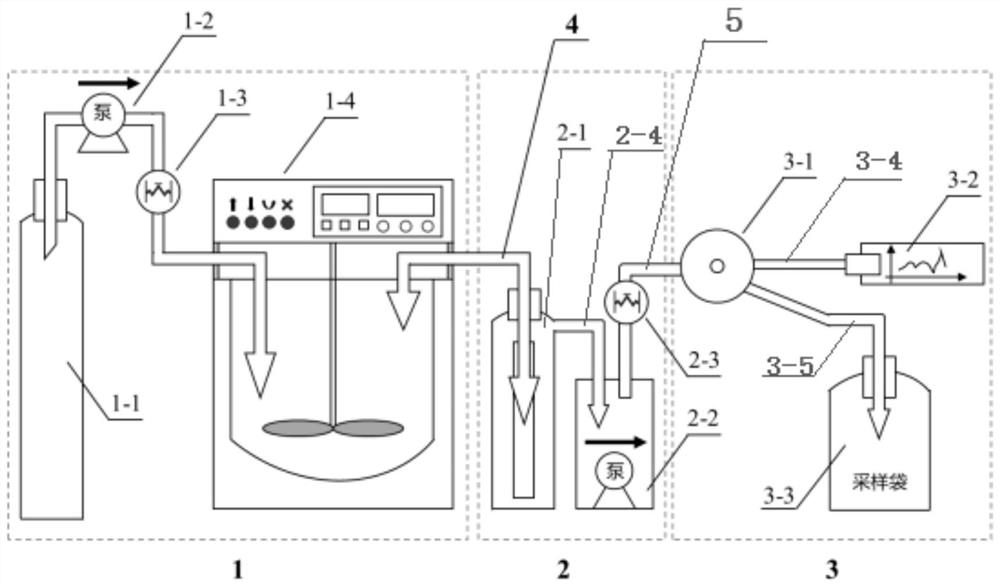

[0030] Specific implementation mode one: combine figure 1 This embodiment is described. An asphalt mixture smoke detection / collection integrated device in this embodiment includes a smoke generating unit 1, a particle filter unit 2, a smoke processing unit 3, a first external gas pipeline 4 and The second external gas transmission pipeline 5, the flue gas generating unit 1 is connected to the particle filter unit 2 through the first external gas transmission pipeline 4, and the particle filter unit 2 is connected to the flue gas treatment unit through the second external gas transmission pipeline 5 3 connections.

specific Embodiment approach 2

[0031] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the flue gas generating unit 1 in this embodiment includes a gas tank 1-1, a nitrogen input pump 1-2, a first flow meter 1-3, an asphalt mixing structure 1-4 and a third external The gas pipeline 1-5, the gas tank 1-1 and the asphalt mixing structure 1-4 are connected through the third external gas pipeline 1-5, and the third external gas pipeline 1-5 is provided with a nitrogen input pump 1-2 and a first flow meter 1-3.

[0032] The asphalt mixture mixing device can ensure that the asphalt mixture is fully stirred evenly, and the mixing time and temperature can be controlled.

[0033] The type of gas in the gas tank 1-1 is nitrogen. As a colorless and odorless inert gas, nitrogen is less dense than air and has high chemical stability under normal temperature conditions.

[0034] Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

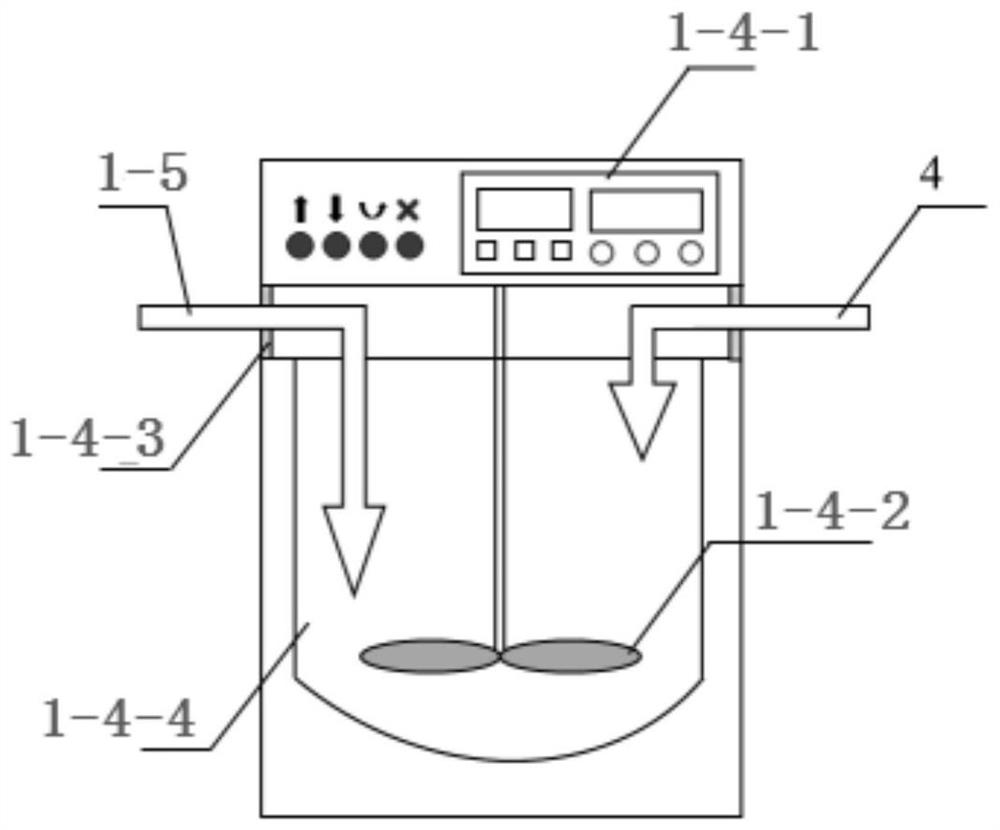

[0035] Specific implementation mode three: combination figure 2 Describe this embodiment, the asphalt mixture mixing structure 1-4 of this embodiment includes a motor, a temperature time controller 1-4-1, a stirring fan blade 1-4-2, a sealing tape 1-4-3 and a heating and mixing pot 1 -4-4, the right side of the sealing strip 1-4-3 is provided with a round hole equal to the diameter of the first external air pipe 4, and the left side of the sealing strip 1-4-3 is provided with the third external air pipe 4. The gas pipeline 1-5 has equal-diameter round holes, the upper end of the sealing tape 1-4-3 is attached to the lower surface of the temperature and time controller 1-4-1, and the lower end of the sealing tape 1-4-3 is connected to the heating and mixing pot The upper surface contact, the stirring fan blade 1-4-2 is located in the heating and mixing pot 1-4-4, the motor is installed at the rear of the temperature time controller 1-4-1, and the output shaft of the motor is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com