Method for preparing MLA test resin polished section from collophanite powder sample

A technology for sample preparation and collophosphate rock, applied in the field of collophosphate powder sample preparation MLA test resin light sheet, which can solve the problems of long secondary inlay time, poor dispersibility of collophosphate rock, and unsatisfactory test results, and achieve consistency Good, high accuracy, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

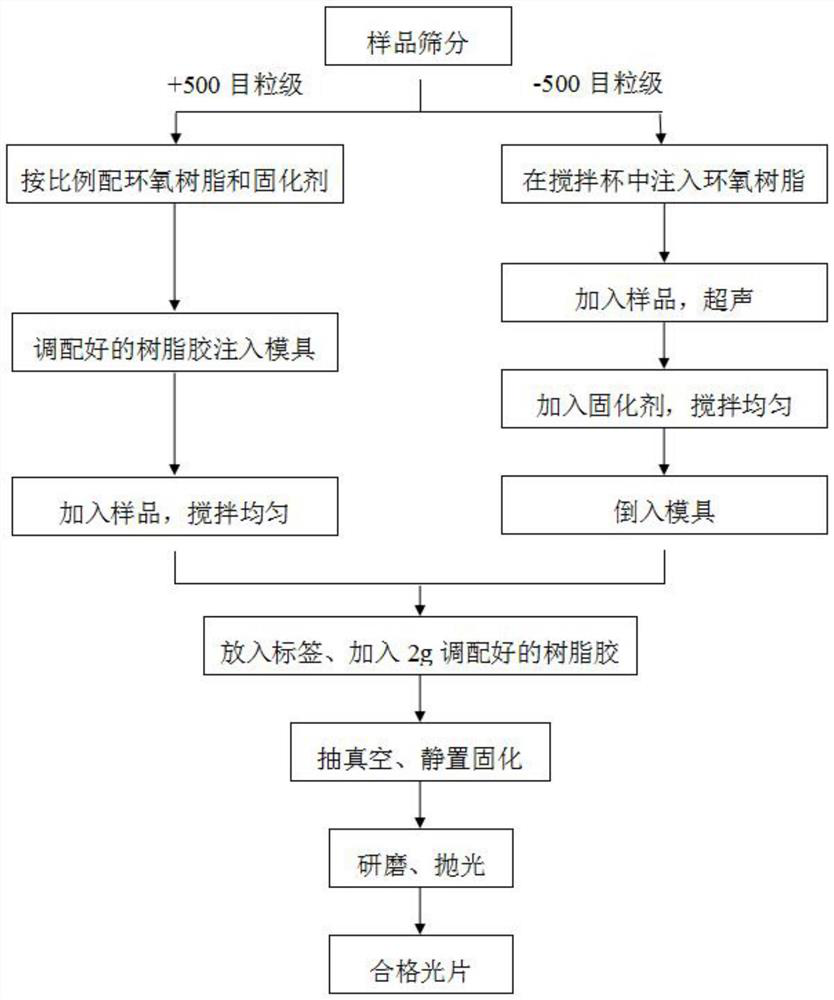

[0028] figure 1 Shown is a kind of method for preparing MLA test resin light sheet of collophosite powder sample, and its specific implementation steps are as follows:

[0029] (1) The lumpy or coarse-grained glenite or its tailings samples are processed into finer-grained samples by crushing and grinding, and processed by wet sieving with 200 mesh, 300 mesh, 400 mesh, and 500 mesh sieves Sieve the final or powdery samples, then filter, dry and weigh the sieved samples of each particle size, and finally shrink the samples of each particle size to 1~2g for later use. If the sample is relatively coarse, it can be re-sieved at 200°C for several particle fractions.

[0030] (2) According to the weight ratio of 25:3, pour a sufficient amount of epoxy resin glue and curing agent into the mixing cup in turn and stir well, and let it stand for 10-20 minutes to let the air bubbles overflow. The resin glue required for each resin light sheet is about 7g, and the amount of the prepared...

Embodiment 2

[0036] Use a collophosite sample to prepare an MLA test resin light sheet, and prepare the sample through the following steps:

[0037] 1. The powdered colloidal rock samples are sieved with 200 mesh, 300 mesh, 400 mesh, and 500 mesh sieves in turn, and the sieved samples of each particle size are filtered, dried, weighed, and shrunk to 1 ~ 2g spare.

[0038] 2. Prepare 30g of epoxy resin glue and curing agent according to the weight ratio of 25:3 for later use.

[0039] 3. Prepare a sample label of appropriate size and fill in the relevant information of the sample, and prepare 5 mounting molds.

[0040] 4. Inject 6.25g of epoxy resin glue into a mixing cup, then add 1g of samples with a particle size of -500 mesh, and stir clockwise with a stirring rod for 2 minutes. Add water above 40°C into the ultrasonic cleaner, and put the mixing cup into the ultrasonic cleaner for 1 hour of ultrasonication.

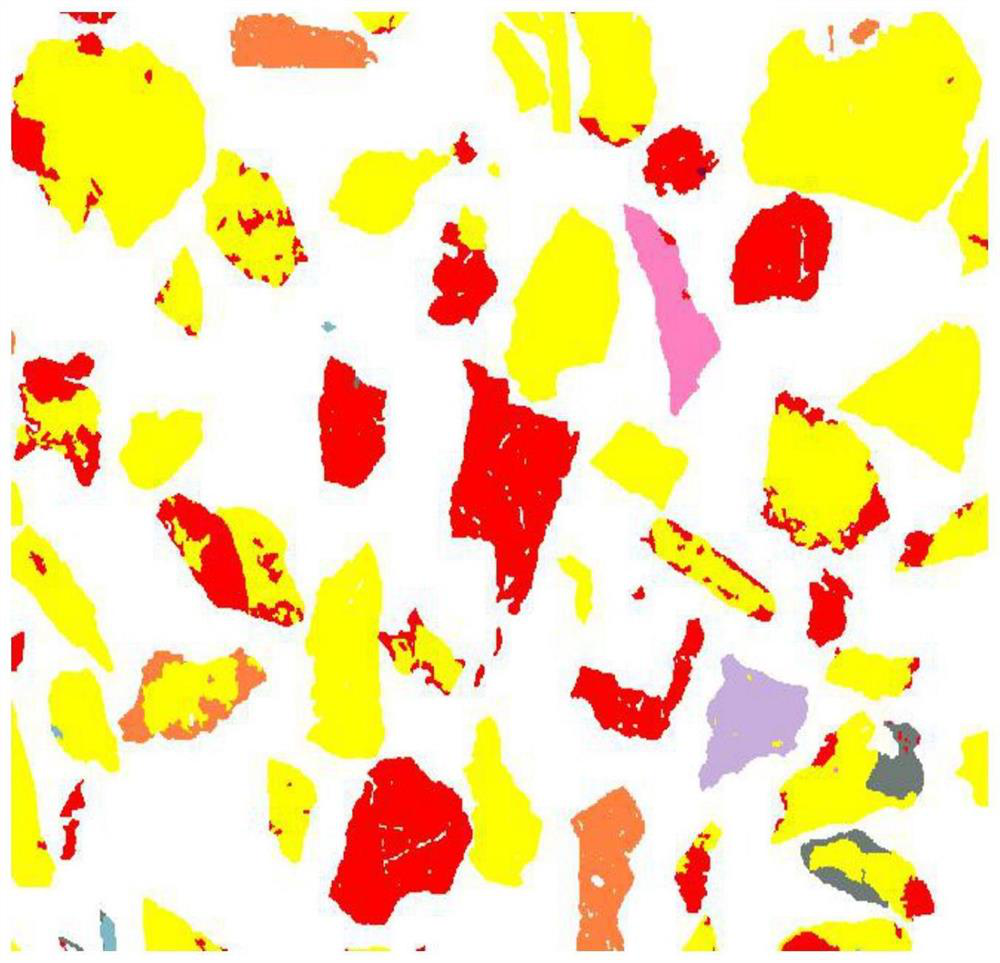

[0041] 5. Take 4 sample mounting molds, inject 5g of prepared resin glue i...

Embodiment 3

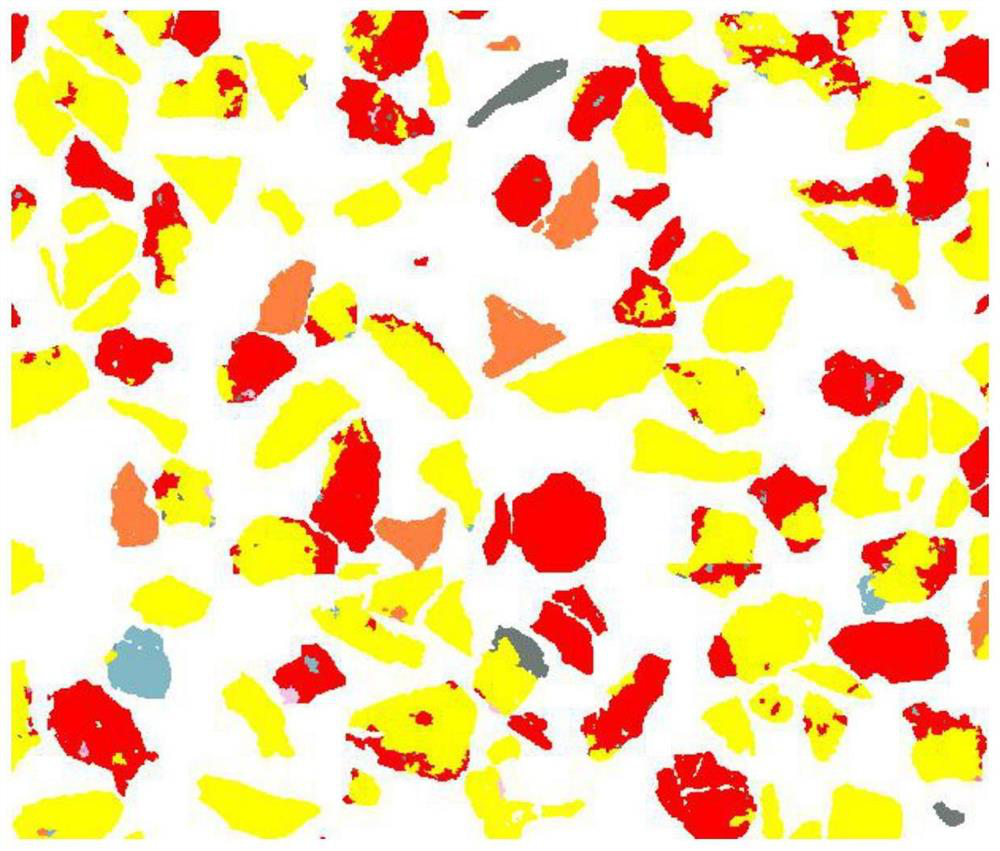

[0045] At present, the reverse flotation process is mostly used for the removal of impurities and phosphorus in collophanite. The fineness of reverse flotation tailings is relatively finer, and the sample preparation is more difficult. Use a collophosite reverse flotation tailings sample to prepare an MLA test resin light sheet, and prepare the sample through the following steps:

[0046] 1. Sieve the tailings samples of powdered colloidal reverse flotation with 200-mesh, 300-mesh, 400-mesh, and 500-mesh sieves in turn, and filter, dry, and weigh the sieved samples of each particle size , and shrink down to 1-2g for later use.

[0047] 2. Prepare 30g of epoxy resin glue and curing agent according to the ratio of 25:3 by weight.

[0048] 3. Prepare a sample label of appropriate size and fill in the relevant information of the sample, and prepare 5 mounting molds.

[0049] 4. Inject 6.25g of epoxy resin glue into a mixing cup, then add 1g of samples with a particle size of -50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com