Automatic and intelligent automobile instrument desk defect detection method

A technology for automotive instrumentation and defect detection, which is applied in the direction of optical test defects/defects, instruments, measuring devices, etc., can solve problems such as the inability to effectively guarantee product quality, and achieve the effect of highly automated detection, high-efficiency interoperability, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

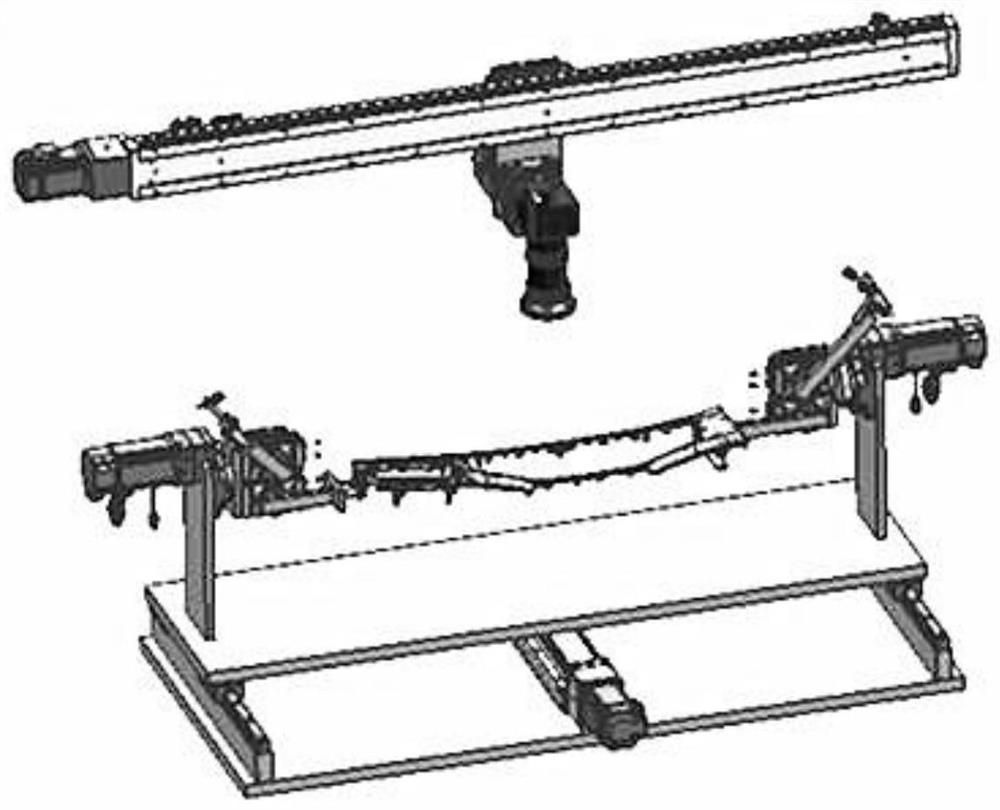

[0018] figure 1 , 2 , 3 and 4, an automated and intelligent automobile instrument panel defect detection method adopts an automated detection assembly line to collect the inspected pictures, and on the basis of the collected pictures, combined with the application software unit in the PC, Train an artificial intelligence model to detect defects in a car dashboard; include the following steps.

[0019] figure 1 , 2 , 3, and 4, Step 1: Define the defect of the inspected product, specifically for the dashboard products of different models, colors and shadings of automobiles, the type and attribute of the inspected defect shall be clearly defined by the identified unit. According to the characteristics of different positions and components of the automobile instrument panel, and the characteristics of different models, the inspection standards and rhythm of the production line, determine the defects that need to be detected intelligently. The characteristics of different posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com