Evaluation method for current collecting capacity of current collecting structure of lithium thionyl chloride battery

A lithium sub-battery and current collection technology, which is applied in the direction of fluid resistance measurement, electricity measurement, and measurement devices, can solve the problems of not being able to directly measure the current transfer capacity and the lack of quantifiable methods for the quality control of current collection structure design, and achieve high operability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

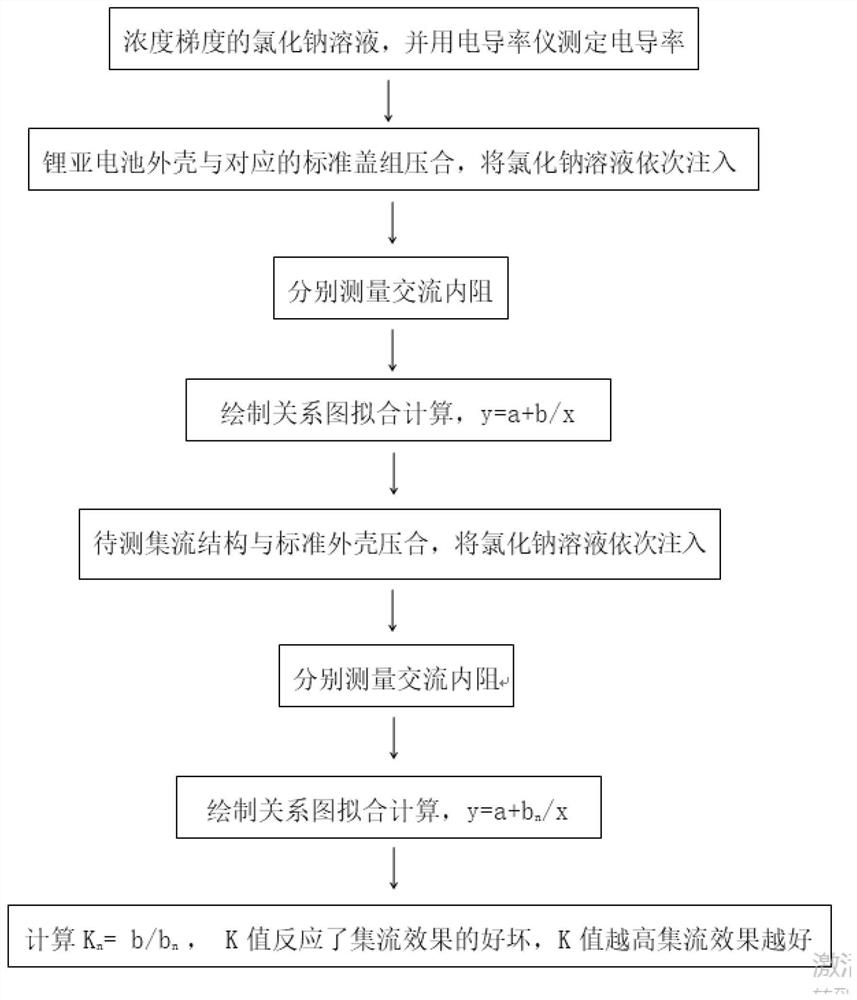

[0037] This embodiment provides a method for evaluating the current collecting capacity of a lithium sub-battery current collecting structure, the flow chart of the evaluation method is as follows figure 1 As shown, the evaluation method specifically includes the following steps:

[0038] (1) In an environment of 20°C, configure a sodium chloride solution with a concentration gradient, use a conductivity meter to measure the conductivity of the above sodium chloride aqueous solution, and record that the concentration of the sodium chloride solution is shown in Table 1 below :

[0039] Table 1

[0040]

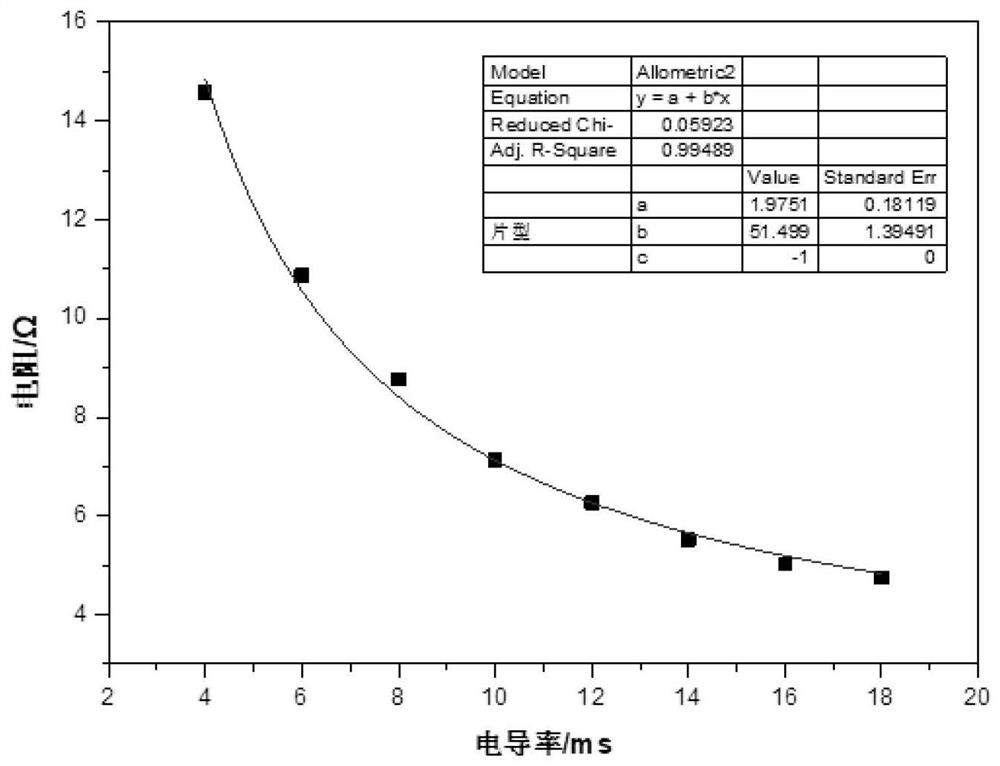

[0041] (2) Press the ER 26500 lithium sub-battery standard casing with the corresponding standard cover group, inject the above-mentioned sodium chloride solution through the injection hole in sequence, the volume of the injected sodium chloride solution is 15ml, use a clamp to ensure The battery is placed vertically, and the two ends of the fixture are connected to the wi...

Embodiment 2

[0050] This embodiment provides a method for evaluating the current collecting capacity of a lithium sub-battery current collecting structure, and the evaluating method includes the following steps:

[0051] (1) In an environment of 20°C, configure a sodium chloride solution with a concentration gradient, use a conductivity meter to measure the conductivity of the above sodium chloride aqueous solution, and record that the concentration of the sodium chloride solution is shown in Table 3 below :

[0052] table 3

[0053]

[0054] (2) Press the ER 26500 lithium sub-battery standard casing with the corresponding standard cover group, inject the above-mentioned sodium chloride solution through the injection hole in sequence, the volume of the injected sodium chloride solution is 15ml, use a clamp to ensure The battery is placed vertically, and the two ends of the fixture are connected to the wires, and the positive and negative poles of the battery case are connected. In an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com