Electrochemical device and electronic device

An electrochemical, edge zone technology, applied in the field of electronics, to avoid the risk of spontaneous combustion or explosion, improve safety, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

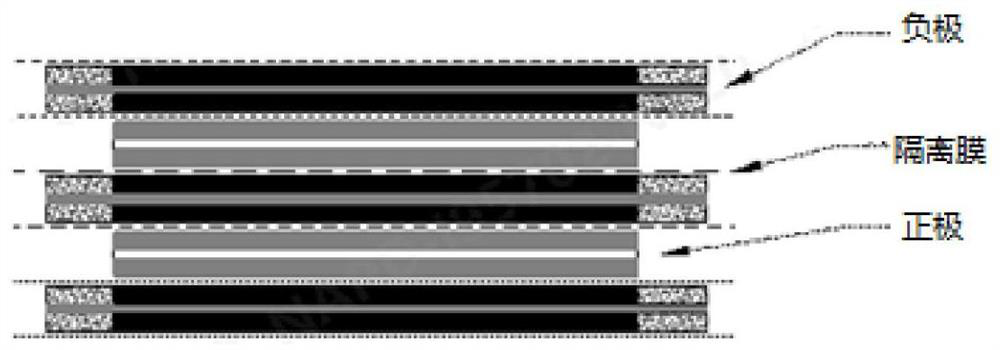

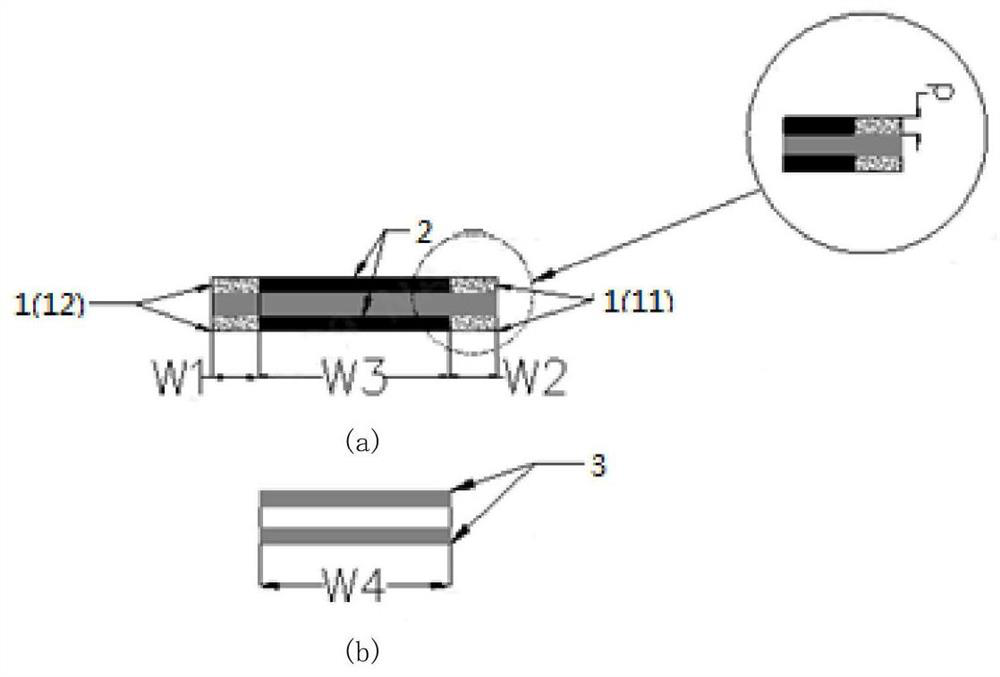

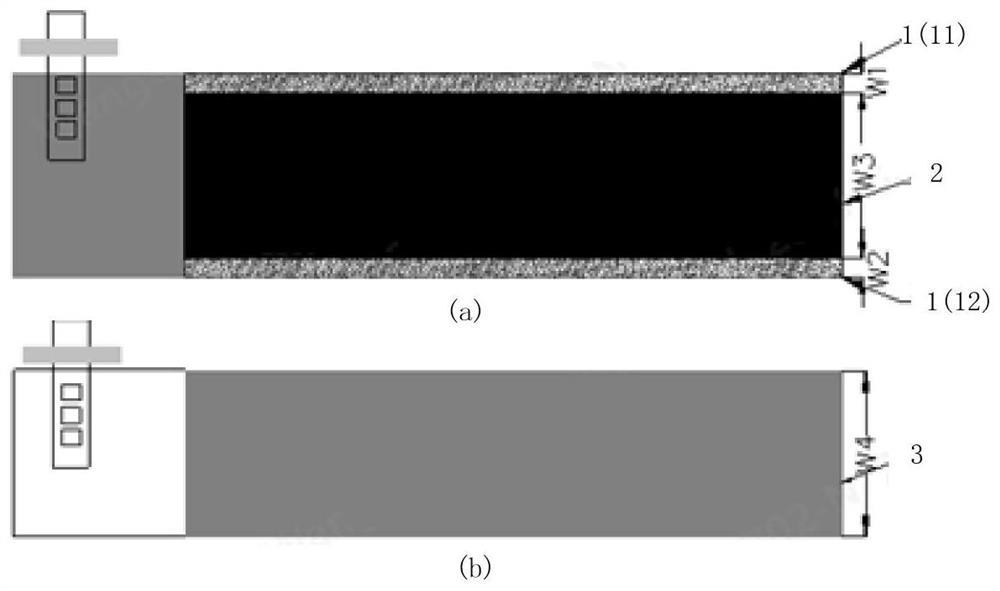

[0046] Preparation of the positive electrode: Dissolve the positive electrode material lithium cobaltate (gram capacity: 181mAh / g), conductive carbon black, and binder polyvinylidene fluoride (PVDF) in N-formazan at a weight ratio of 97.6:1.1:1.3 In the base pyrrolidone (NMP) solution, the positive electrode slurry was formed. Using aluminum foil as the positive electrode collector, the positive electrode slurry is coated on the positive electrode collector, and the coating amount is 18.69mg / cm 2 , after drying, cold pressing, and cutting, the positive electrode is obtained. The compacted density of the positive active material layer during the cold pressing process is 4.15g / cm 3 , the width W4 of the positive electrode after slitting is 92mm.

[0047] Preparation of negative electrode sheet: 20% SiO x Material (gram capacity is 1545mAh / g) and 80% graphite material (gram capacity is 355mAh / g), dispersant (sodium carboxymethyl cellulose) and binder acrylate, conductive agent ...

Embodiment 2

[0052] The difference between Example 2 and Example 1 lies in the preparation of the negative electrode, and the rest of the steps are the same.

[0053] Embodiment 2 40% SiOx material (gram capacity is 1545mAh / g) and 60% graphite material (gram capacity is 355mAh / g), dispersant (sodium carboxymethyl cellulose) and binder acrylate, conductive agent ( Conductive carbon black, CNT) is dissolved in deionized water at a ratio of 93.0:1.0:5.5:0.5 by weight to form slurry 1; 100% graphite material (355mAh / g in gram capacity), binder styrene-butadiene rubber, The conductive agent (conductive carbon black, CNT) was dissolved in deionized water at a weight ratio of 97.7:0.6:0.7 to form slurry 2. Copper foil with a thickness of 10 μm was used as the negative electrode current collector, and slurry 2 was preferentially coated on the negative electrode current collector, and the coating amount was 9.83 mg / cm 2 , dried to obtain the negative electrode active material layer 2, and then the...

Embodiment 3

[0055] The difference between Example 3 and Example 1 lies in the preparation of the negative electrode, and the rest of the steps are the same.

[0056] Embodiment 3 80% SiOx material (gram capacity is 1545mAh / g) and 20% graphite material (gram capacity is 355mAh / g), dispersion agent (sodium carboxymethyl cellulose) and binding agent acrylate, conductive agent ( Conductive carbon black, CNT) is dissolved in deionized water according to the ratio of 88.5:1.5:8.0:2.0 by weight to form slurry 1; 100% graphite material (gram capacity is 355mAh / g), binder styrene-butadiene rubber, The conductive agent (conductive carbon black, CNT) was dissolved in deionized water at a weight ratio of 97.7:0.6:0.7 to form slurry 2. Copper foil with a thickness of 10 μm was used as the negative electrode current collector, and slurry 2 was preferentially coated on the negative electrode current collector, and the coating amount was 9.83 mg / cm 2 , dried to obtain the negative electrode active mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com