Hydride/air battery capable of synchronously treating waste acid and waste alkali and generating electricity

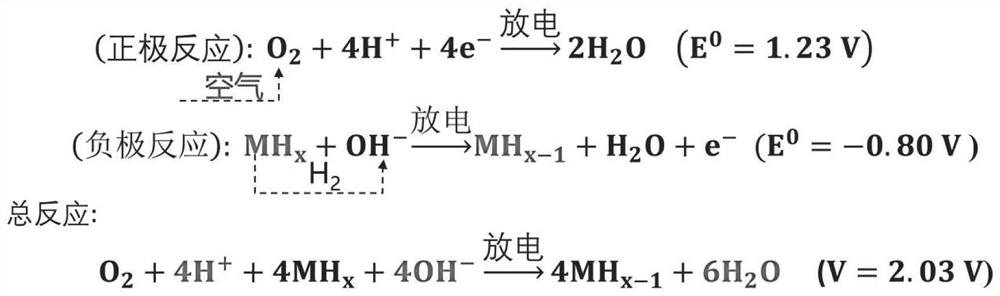

A synchronous processing and hydride technology, applied in the fields of chemical industry, environment and energy, can solve the problems of high utilization rate of resources and lack of synchronous processing technology, and achieve the effect of improving utilization rate of resources and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

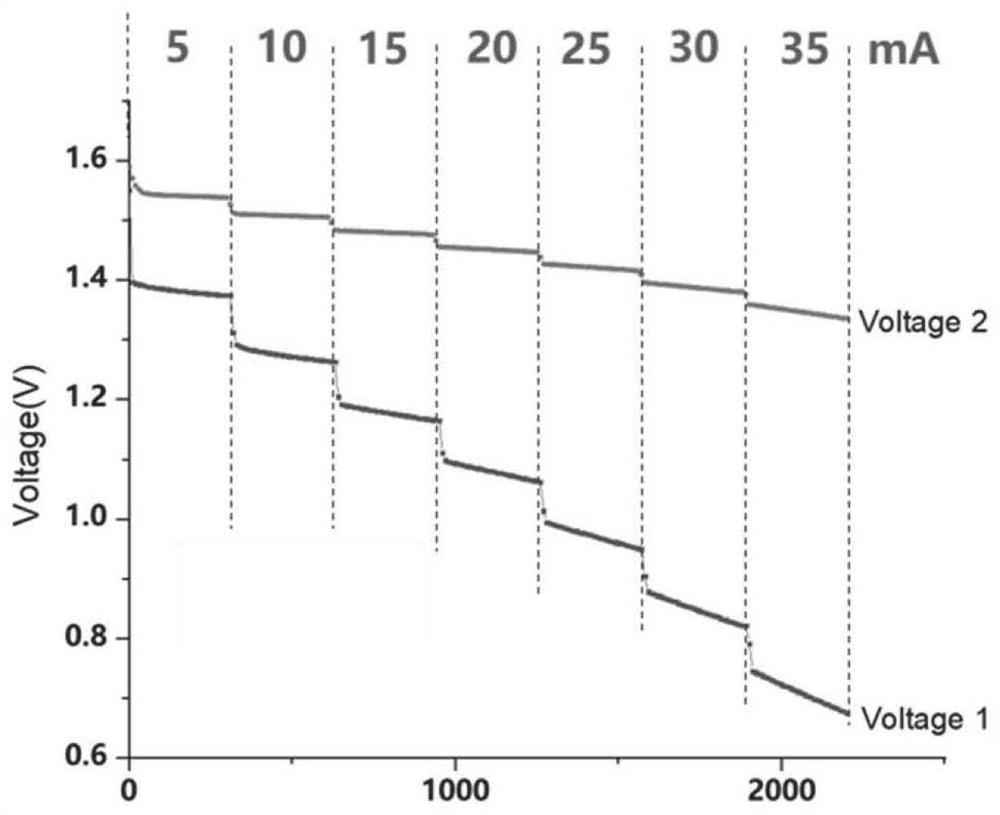

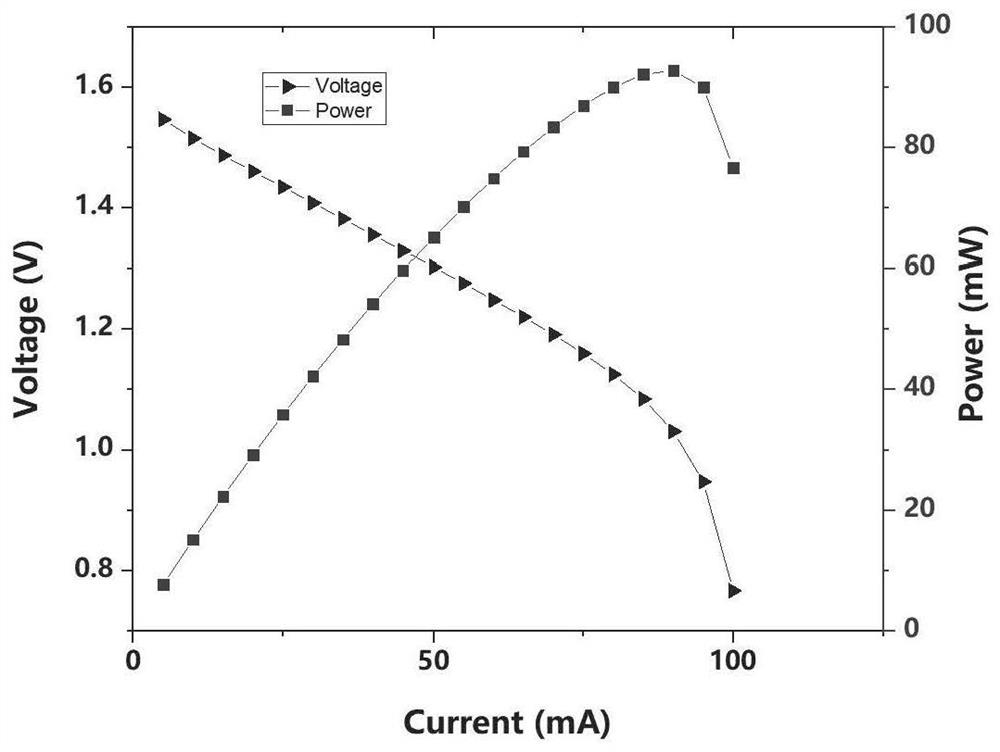

[0034] The present embodiment comprises following process and test steps:

[0035] 1) Electrolyte preparation: 35mL of 0.5M sulfuric acid was prepared as the simulated waste acid cathode electrolyte. Configure 35mL of 1M KOH solution as the simulated spent alkali negative electrode electrolyte.

[0036] 2) Preparation of positive electrode: 30 mg of platinum-carbon catalyst and 0.4 mL of 50 wt % polytetrafluoroethylene (PTFE) binder solution were mixed and ground, then coated on the surface of hydrophobic carbon cloth, and placed in an oven at 80° C. for 2 hours.

[0037] 3) Preparation of the negative electrode: take out the metal hydride (MH) from the fully discharged rechargeable battery, mix and grind 1gMH, 50mg carbon black (Cabot), 1mL50wt% PTFE solution, put it into an oven and dry it until Cement-like, get the active substance, apply the active substance on the upper half surface of 3*6cm, 0.5mm thick nickel foam, cut the nickel-plated steel strip 6cm long, 0.15*8mm t...

Embodiment 2

[0043] Include following process and test step in the present embodiment:

[0044] 1) Electrolyte preparation: 35mL of 1M sulfuric acid was prepared as the simulated waste acid cathode electrolyte. Configure 35mL of 1M KOH solution as the simulated spent alkali negative electrode electrolyte. Different from Example 1, this example uses a more acidic spent acid solution to further prove the practicability of the battery.

[0045] 2) Preparation of positive electrode: 30 mg of platinum-carbon catalyst and 0.4 mL of 50 wt % PTFE binder solution were mixed and ground, coated on the surface of hydrophobic carbon cloth, and placed in an oven at 80° C. for 2 hours.

[0046] 3) Preparation of the negative electrode: take out the metal hydride (MH) from the fully discharged rechargeable battery, mix and grind 1gMH, 50mg carbon black (Cabot), 1mL50wt% PTFE solution, put it into an oven and dry it until Cement-like, get the active substance, apply the active substance on the upper half...

Embodiment 3

[0053] The present embodiment comprises following process and test steps:

[0054] 1) Electrolyte preparation: 17mL of 1M sulfuric acid was prepared as the simulated spent acid cathode electrolyte. Configure 17mL of 1M KOH solution as the simulated spent alkali negative electrode electrolyte. In this embodiment, less electrolyte is used to explore the practicability of the battery device.

[0055] 2) Preparation of positive electrode: 30 mg of platinum-carbon catalyst and 0.4 mL of 50 wt % PTFE binder solution were mixed and ground, coated on the surface of carbon cloth, and placed in an oven at 80° C. for 2 hours.

[0056] 3) Preparation of the negative electrode: take out the metal hydride (MH) from the fully discharged rechargeable battery, mix and grind 1gMH, 50mg carbon black (Cabot), 1mL50wt% PTFE solution, put it into an oven and dry it until Cement-like, get the active substance, apply the active substance on the upper half surface of 3*6cm, 2mm thick nickel foam, cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com