Preparation method of net pressing copper nanometer packed bed heat dissipation material

A heat dissipation material, copper nanotechnology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of unknown boiling heat transfer effect, achieve excellent phase change heat performance, enhanced heat transfer performance, and reduced detachment diameter small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a pressed mesh copper nano-stacked bed heat dissipation material, comprising the following steps:

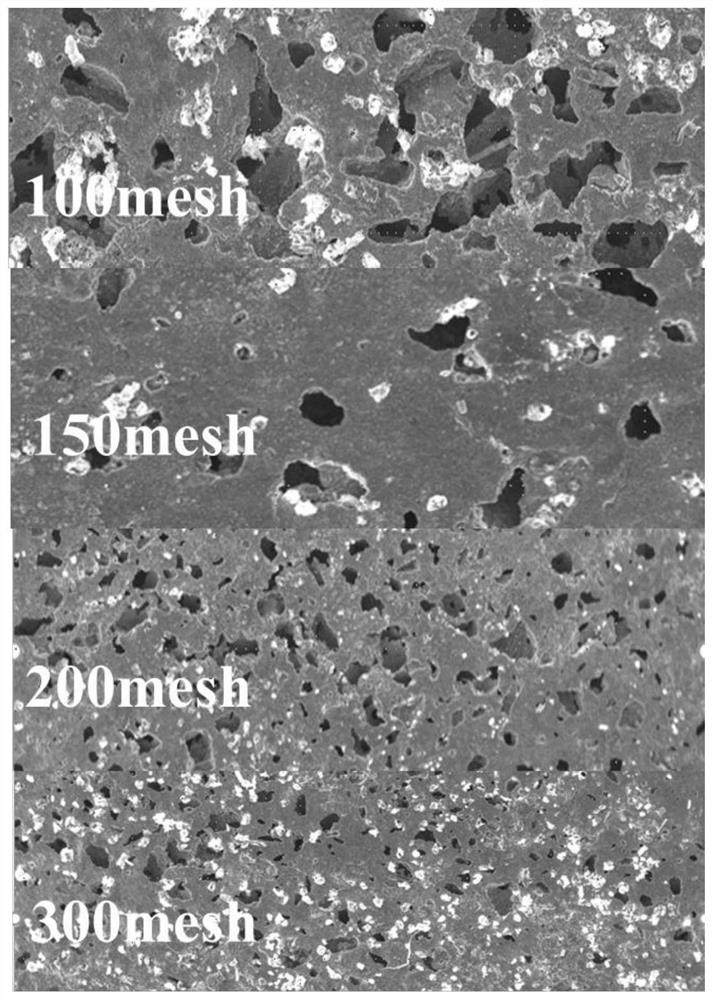

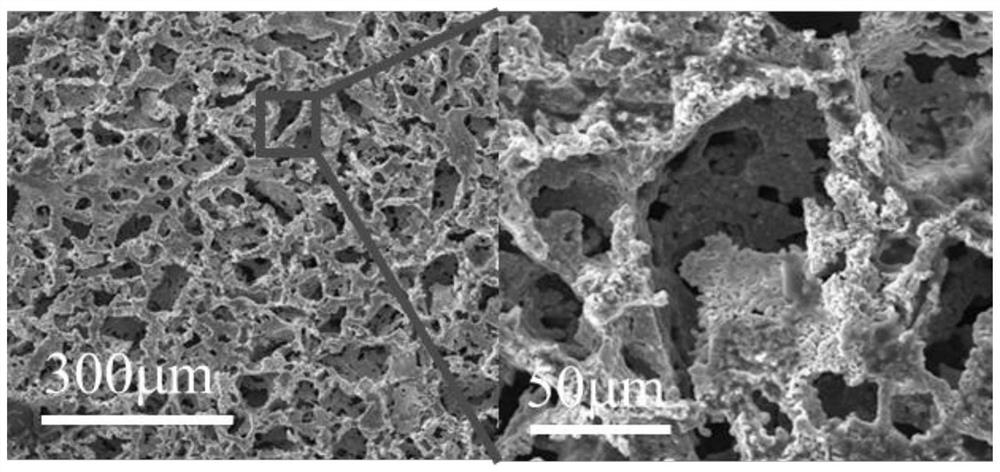

[0028] a. 100 mesh, 150 mesh, 200 mesh, and 300 mesh sieves are used to sieve sodium chloride particles with four particle sizes, and then the sodium chloride particles with four particle sizes are mixed with 500nm nano-copper powder according to the A certain proportion is put into a ball mill for 20 minutes, the mass ratio of nano-copper powder and sodium chloride particles is 1:4, and after mixing evenly, mixed particles Ⅰ, mixed particles Ⅱ, mixed particles Ⅲ, and mixed particles Ⅳ are obtained;

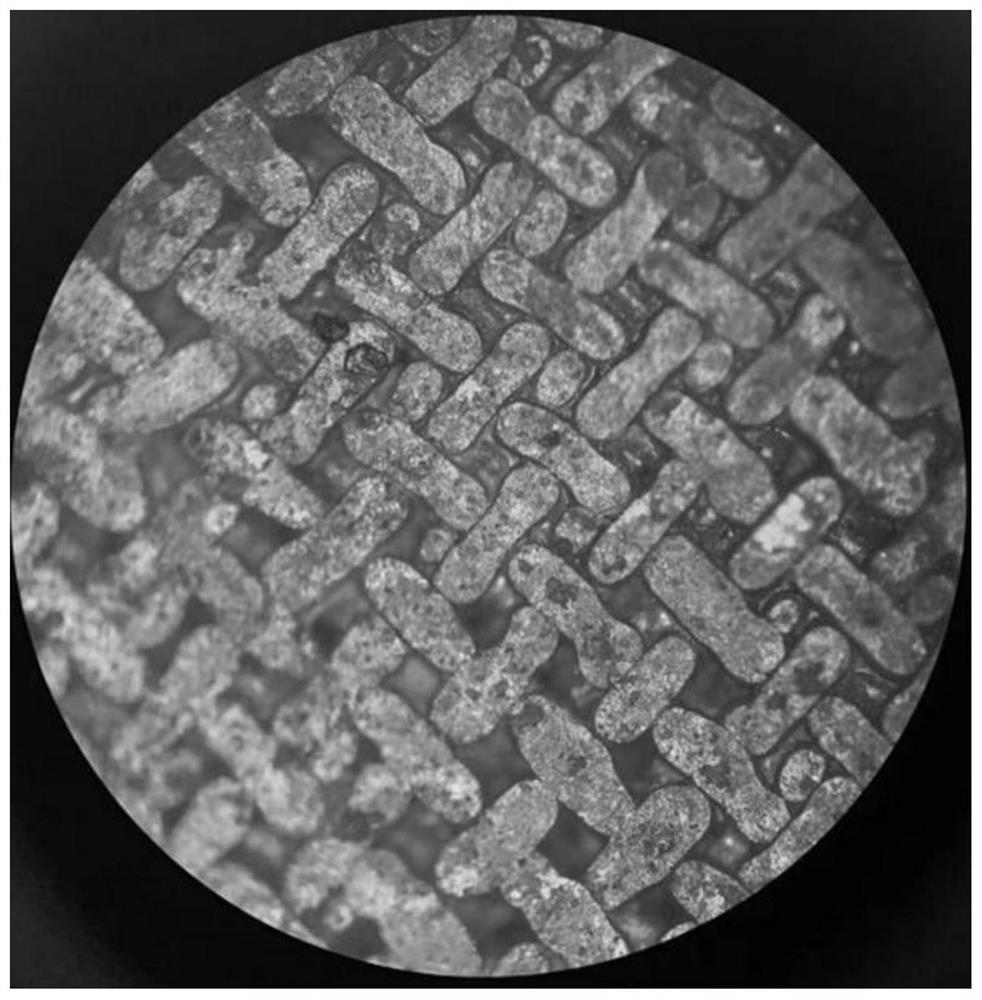

[0029] b. Lay the mixed granules IV, mixed granules III, mixed granules II, and mixed granules I into the tableting mold from bottom to top, laying four layers in total, and the thickness of each layer is 2mm. After each layer is laid, use the mold to press The copper nano-stacked bed is flatly obtained, and finally the copper mesh is placed on the upp...

Embodiment 2

[0035] A method for preparing a pressed mesh copper nano-stacked bed heat dissipation material, comprising the following steps:

[0036] a. 100 mesh, 150 mesh, 200 mesh, and 300 mesh sieves are used to sieve sodium chloride particles with four particle sizes, and then the sodium chloride particles with four particle sizes are mixed with 800nm nano-copper powder according to the Put a certain proportion into a ball mill and mill for 17 minutes. The mass ratio of nano-copper powder and sodium chloride particles is 1:3.5. After mixing evenly, mixed particles Ⅰ, mixed particles Ⅱ, mixed particles Ⅲ, and mixed particles Ⅳ are obtained;

[0037] b. Lay the mixed granules IV, mixed granules III, mixed granules II, and mixed granules I into the tableting mold from bottom to top, laying four layers in total, and the thickness of each layer is 3mm. After each layer is laid, use the mold to press The copper nano-stacked bed is flatly obtained, and finally the copper mesh is placed on t...

Embodiment 3

[0042] A method for preparing a pressed mesh copper nano-stacked bed heat dissipation material, comprising the following steps:

[0043]a. 100 mesh, 150 mesh, 200 mesh, and 300 mesh sieves are used to sieve sodium chloride particles with four particle sizes, and then the sodium chloride particles with four particle sizes are mixed with 1000nm nano-copper powder according to the Put a certain proportion into a ball mill for ball milling for 15 minutes. The mass ratio of nano-copper powder and sodium chloride particles is 1:3. After mixing evenly, mixed particles I, mixed particles II, mixed particles III, and mixed particles IV are obtained;

[0044] b. Lay the mixed granules IV, mixed granules III, mixed granules II, and mixed granules I into the tableting mold from bottom to top, laying four layers in total, and the thickness of each layer is 4mm. After each layer is laid, use the mold to press The copper nano-stacked bed is flatly obtained, and finally the copper mesh is pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com