Hot galvanizing plate type radiator for SF6 gas insulation transformer

A technology of gas insulation and heat sink, applied in transformer/inductor cooling, transformer/inductor corrosion protection, transformer/inductor components, etc., can solve problems such as threats to transformer operation safety, paint peeling and failure, and reach the anti-corrosion period Long-term, low processing cost, and the effect of increasing the life and safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

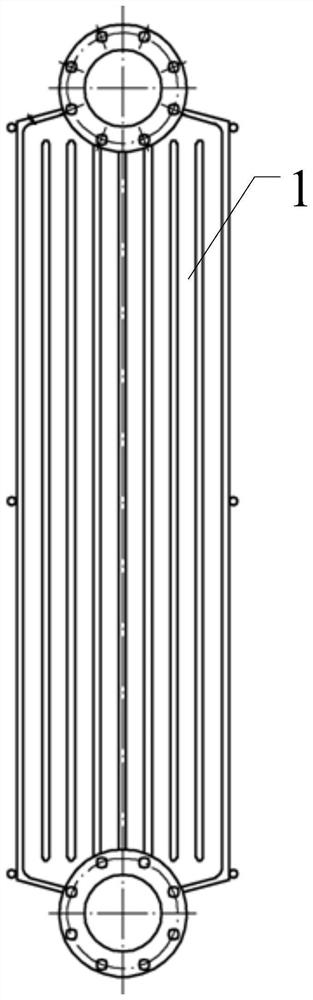

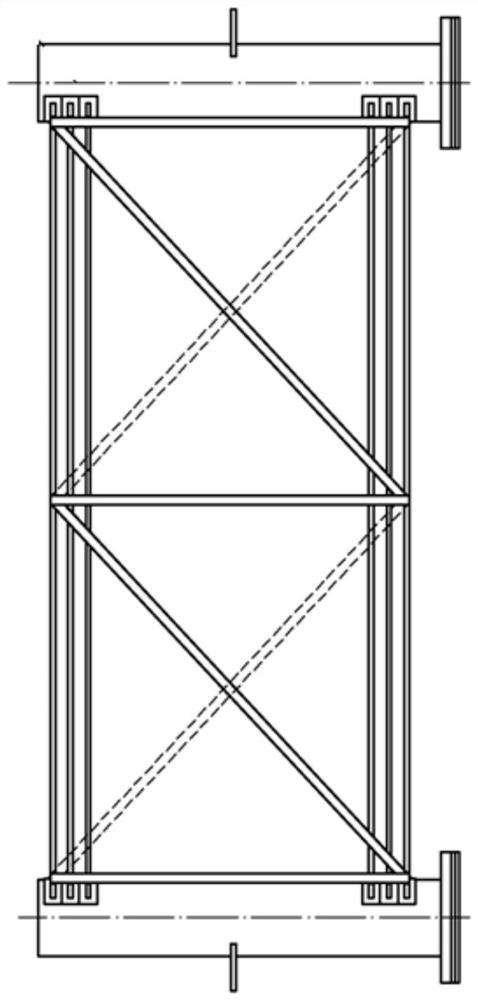

[0024] figure 1 A kind of SF for the present invention 6 A schematic structural view of an embodiment of a hot-dip galvanized sheet radiator for a gas-insulated transformer, figure 2 A kind of SF for the present invention 6 Side view of an embodiment of a hot-dip galvanized fin radiator for a gas-insulated transformer. The invention provides a SF 6 Hot dip galvanized fin radiators for gas insulated transformers, including SF 6 Gas radiator 1, the SF 6 A layer of zinc is attached to the surface of the gas radiator; achieving SF 6 The anti-corrosion requirements of gas radiators have a long anti-corrosion period and can adapt to harsher environmental requirements. Galvanized layer and SF 6 The gas radiator steel is metallurgically bonded and becomes a part of the steel surface, so the durability of the coating is more reliable. SF 6 Every part of the surface of the gas radiator can be galvanized, even in the recesses, sharp corners and hidden places can receive full pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com