AGM diaphragm for winding battery and preparation method of AGM diaphragm

A diaphragm and battery technology, applied in the field of AGM diaphragm for winding batteries and its preparation, can solve the problems that the AGM diaphragm cannot meet the requirements of wound lead-acid batteries, and achieve the prevention of lead dendrite short circuit, small internal resistance, and acid absorption good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

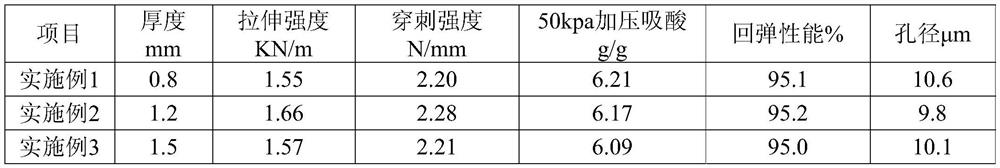

Examples

Embodiment 1

[0025] An AGM diaphragm for winding batteries, the thickness of which is 0.8 mm, comprises the following components in parts by weight: 85 parts of glass fiber, 3 parts of silica airgel, and 6 parts of molecular sieve.

[0026] (1) Put the mixed glass fiber and water into the deflagging machine 1, and decompose for 10 minutes; then add 4 parts of 85% sulfuric acid to disperse, so that the fibers are evenly dispersed;

[0027] (2) Gravity dehydration of the uniformly dispersed slurry in the forming section to obtain a wet paper web with high water content;

[0028] (3) Silica airgel and ground molecular sieves are added into the deflagging machine two, and water and 0.5 part of 85% sulfuric acid are added to disperse evenly;

[0029] (4) Immerse the wet paper web prepared in step (2) into the suspension of silica aerogel and molecular sieve uniformly dispersed in step (3), and carry out soaking treatment; the wet paper web after soaking is carried out gravity dehydration and mo...

Embodiment 2

[0032] An AGM diaphragm for winding batteries, the thickness of which is 1.2 mm, comprises the following components in parts by weight: 92 parts of glass fibers, 4 parts of silica airgel, and 4 parts of molecular sieves.

[0033] (1) Put the mixed glass fiber and water into the deflagging machine 1, and decompose for 10 minutes; then add 4 parts of 85% sulfuric acid to disperse, so that the fibers are evenly dispersed;

[0034] (2) Gravity dehydration of the uniformly dispersed slurry in the forming section to obtain a wet paper web with high water content;

[0035] (3) Silica airgel and ground molecular sieves are added into the deflagging machine two, and water and 0.5 part of 85% sulfuric acid are added to disperse evenly;

[0036] (4) Immerse the wet paper web prepared in step (2) into the suspension of silica aerogel and molecular sieve uniformly dispersed in step (3), and carry out soaking treatment; the wet paper web after soaking is carried out gravity dehydration and ...

Embodiment 3

[0039] An AGM diaphragm for winding batteries, the thickness of which is 1.5 mm, comprises the following components in parts by weight: 95 parts of glass fiber, 5 parts of silica airgel, and 5 parts of molecular sieve.

[0040] (1) Put the mixed glass fiber and water into the deflagging machine 1, and decompose for 12 minutes; then add 4 parts of 85% sulfuric acid to disperse, so that the fibers are evenly dispersed;

[0041] (2) Gravity dehydration of the uniformly dispersed slurry in the forming section to obtain a wet paper web with high water content;

[0042] (3) Silica airgel and ground molecular sieves are added into the deflagging machine two, and water and 0.5 part of 85% sulfuric acid are added to disperse evenly;

[0043] (4) Immerse the wet paper web prepared in step (2) into the suspension of silica aerogel and molecular sieve uniformly dispersed in step (3), and carry out soaking treatment; the wet paper web after soaking is carried out gravity dehydration and mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com