Laser welding method for sealing nail

A laser welding and laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of battery scrapping, waste of manpower and material resources, and affecting battery sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

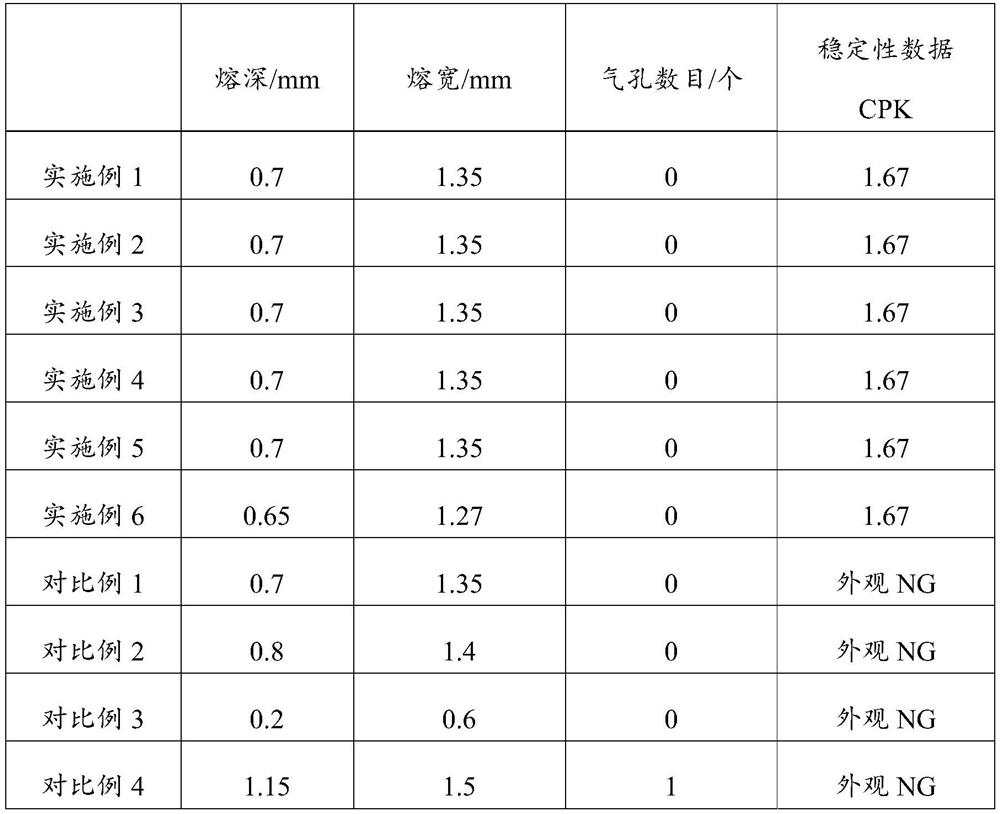

Embodiment 1

[0028] This embodiment 1 provides a laser welding method for sealing nails, the steps are as follows:

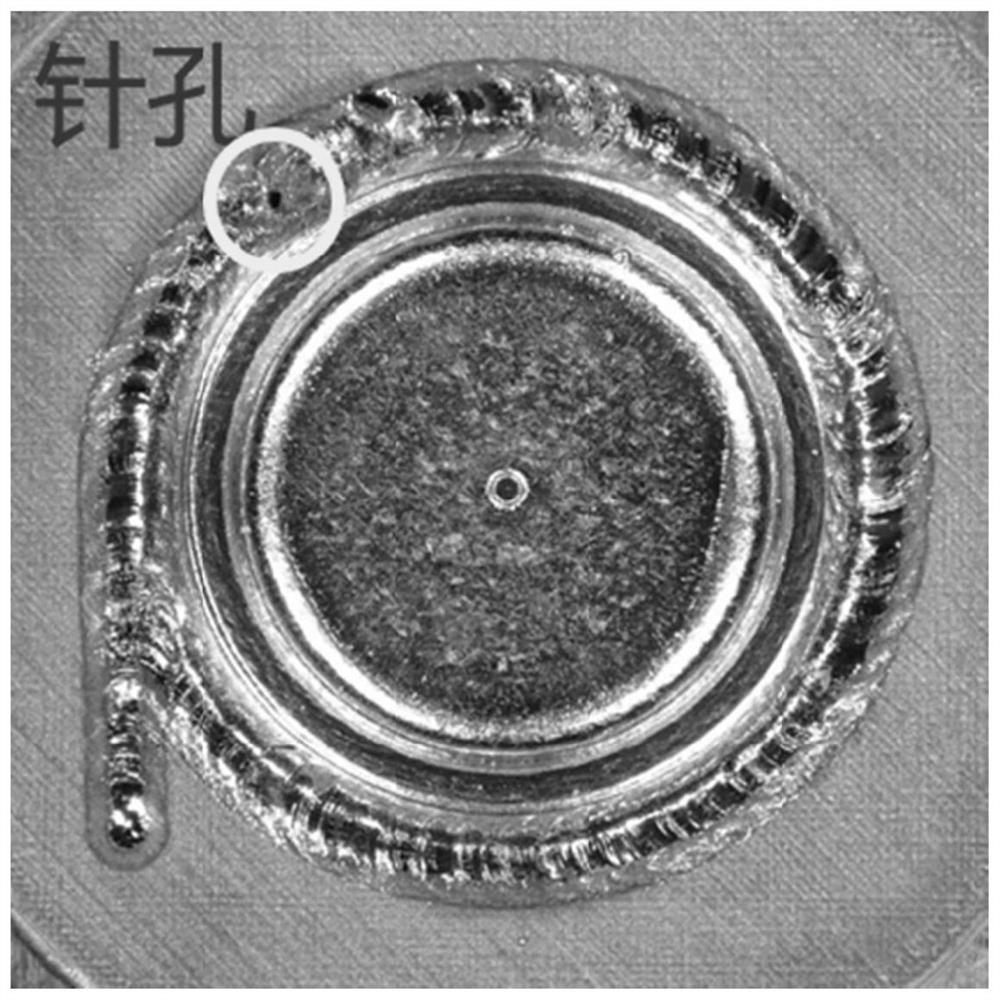

[0029] There is also pre-spot welding before welding, set the parameters of pre-spot welding, the welding peak power of the welding equipment is set at 300W, single-point light; perform pre-spot welding;

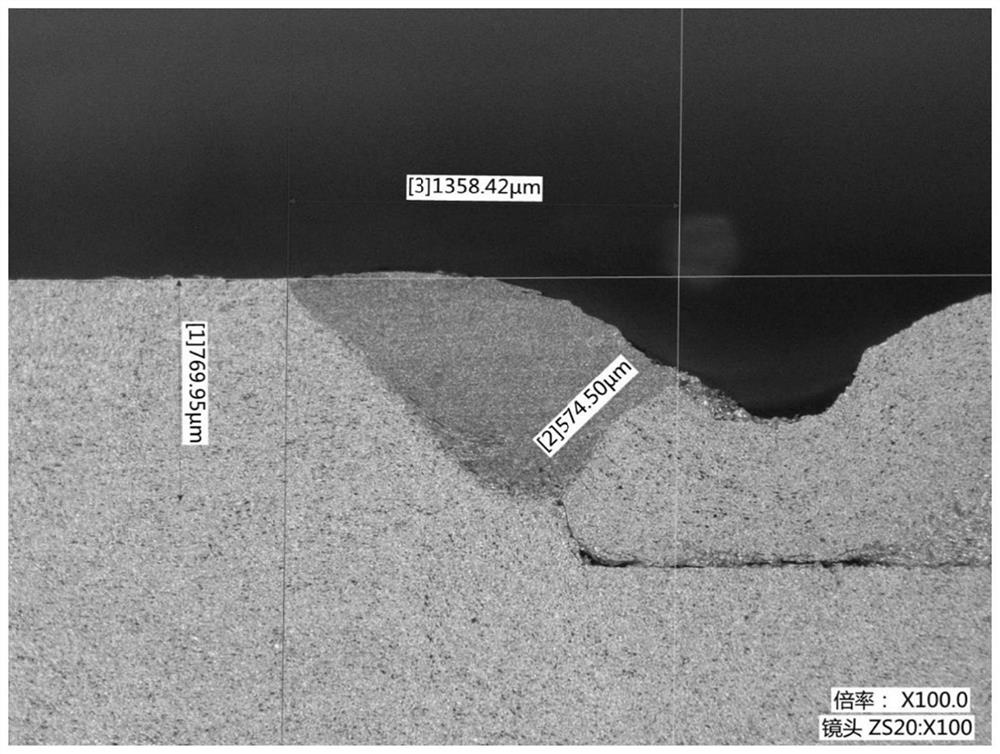

[0030] The welding of the sealing nail is carried out by welding equipment with a laser, the welding track is set on the area to be welded, and the counterclockwise closed-loop welding is carried out according to the welding track in the area to be welded, wherein the laser is modulated to a high level by a control box frequency pulse mode, the laser welding power is 0.8KW, the welding frequency after modulation is 90Hz, the single welding time is 11ms, the welding speed is 30mm / s; the defocus is 1mm; the spot diameter of the focus lens of the welding head of the laser is equal to 0.15 mm.

Embodiment 2

[0032] This embodiment 2 provides a laser welding method for sealing nails, the steps are as follows:

[0033] There is also pre-spot welding before welding, set the parameters of pre-spot welding, the welding peak power of the welding equipment is set at 300W, single-point light; perform pre-spot welding;

[0034] The welding of the sealing nail is carried out by welding equipment with a laser, the welding track is set on the area to be welded, and the counterclockwise closed-loop welding is carried out according to the welding track in the area to be welded, wherein the laser is modulated to a high level by a control box High-frequency pulse mode, laser welding power is 0.8KW, welding frequency after modulation is 80Hz, single welding time is 11ms, welding speed is 30mm / s; defocus is 1mm; laser spot diameter of welding head focusing lens focus is equal to 0.15 mm.

Embodiment 3

[0036] This embodiment 3 provides a laser welding method for sealing nails, the steps are as follows:

[0037] There is also pre-spot welding before welding, set the parameters of pre-spot welding, the welding peak power of the welding equipment is set at 300W, single-point light; perform pre-spot welding;

[0038] The welding of the sealing nail is carried out by welding equipment with a laser, the welding track is set on the area to be welded, and the counterclockwise closed-loop welding is carried out according to the welding track in the area to be welded, wherein the laser is modulated to a high level by a control box High-frequency pulse mode, laser welding power is 0.8KW, welding frequency after modulation is 85Hz, single welding time is 11ms, welding speed is 30mm / s; defocus is 1mm; the spot diameter of the focus lens of the welding head of the laser is equal to 0.15 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Defocus amount | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com