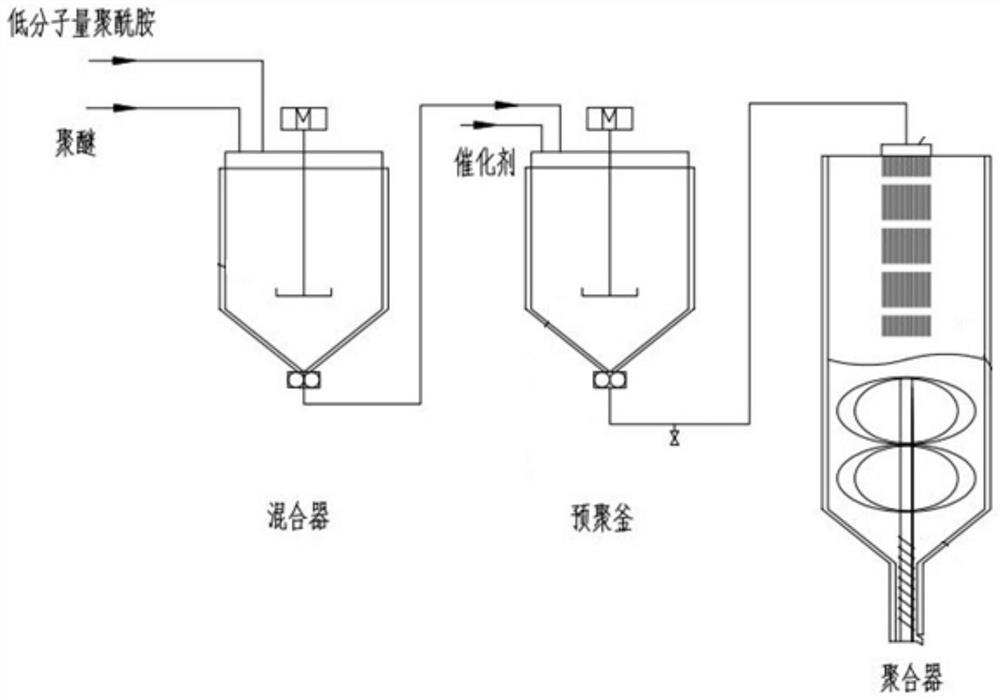

Production process of polyether amide elastomer

A polyetheramide and production process technology, used in the production and preparation of elastomer materials, can solve the problems of inconsistent product viscosity, uneven film formation, poor fluidity, etc., and achieve improved compatibility, good color, and shortened reaction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] A kind of production technology of polyether amide elastomer, comprises the steps:

[0078] Step S1, mixing: the low molecular weight polyamide PA610 (molecular weight: about 1000) with a flow rate of 100Kg / hr and polytetrahydrofuran glycol (molecular weight: 600) with a flow rate of 60Kg / hr are continuously fed into the mixer for mixing. The mixer is heated by heat conduction oil to maintain the temperature of the material at 200°C; the mixer is fed with nitrogen to maintain a slight positive pressure; when the liquid level of the mixer reaches a certain value, the stirring is started, and after 10 minutes, the delivery pump of the mixer is started for feeding. Adjust the delivery rate of the mixer delivery pump to maintain a stable liquid level. By maintaining a certain liquid level, the residence time of the material in the mixer is 10 minutes.

[0079] Step S2, pre-polymerization: when the materials in the mixer are continuously sent into the pre-polymerization tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com