Synchronous phase modifier auxiliary machine noise test method and system

A technology for noise testing and condensers, which is applied in the field of noise testing methods and systems for synchronous condensers and auxiliary equipment. It can solve the problems of large specific surface area of sound sources, dispersion of condensers and auxiliary equipment, and multi-distribution of pipelines, etc., to achieve accurate measurement of surface area, Accurate calculation, improve scientific effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

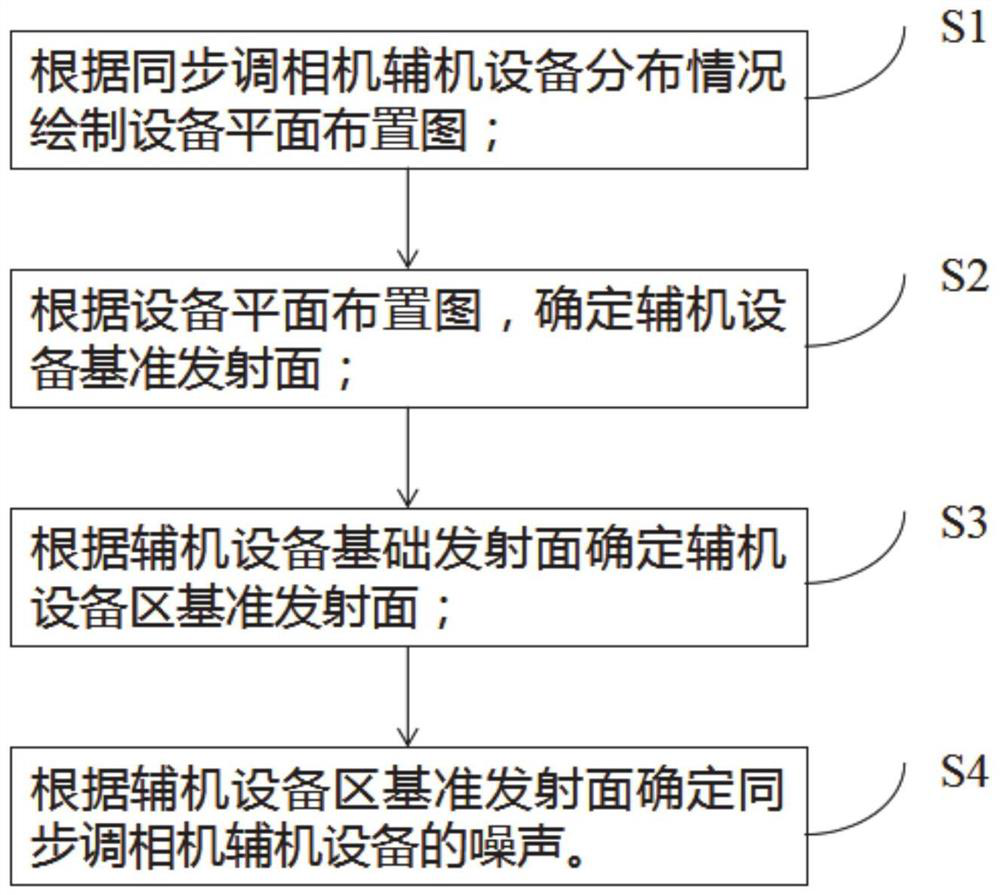

[0037] Such as figure 1 As shown, this embodiment provides a method for testing the noise of synchronous camera auxiliary equipment. This embodiment uses this method as an example to illustrate the server. It can be understood that this method can also be applied to terminals, and can also be applied to The terminal, the server and the system are implemented through the interaction between the terminal and the server. The server can be an independent physical server, or a server cluster or distributed system composed of multiple physical servers, or it can provide cloud services, cloud database, cloud computing, cloud function, cloud storage, network server, cloud communication, intermediate Cloud servers for basic cloud computing services such as software services, domain name services, security service CDN, and big data and artificial intelligence platforms. The terminal may be a smart phone, a tablet computer, a laptop computer, a desktop computer, a smart speaker, a smart...

Embodiment 2

[0070] This embodiment provides a synchronous condenser auxiliary machine noise test system, including:

[0071] The floor plan drawing module is configured to draw the equipment floor plan according to the distribution of synchronous condenser and auxiliary equipment;

[0072] The reference launch surface determination module of the auxiliary equipment is configured to determine the reference launch surface of the auxiliary equipment according to the equipment layout;

[0073] The module for determining the reference emission surface of the auxiliary equipment area is configured to determine the reference emission surface of the auxiliary equipment area according to the basic emission surface of the auxiliary equipment;

[0074] The auxiliary equipment noise determination module of the synchronous condenser is configured to determine the noise of the auxiliary equipment of the synchronous condenser according to the reference emission surface of the auxiliary equipment area. ...

Embodiment 3

[0079] This embodiment provides a computer-readable storage medium, on which a computer program is stored. When the program is executed by a processor, the steps in the method for testing the noise of a synchronous condenser and auxiliary machine as described in the first embodiment above are implemented.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com