Direct-connection magnetic coupling rotating shaft for electric spark forming machine

A magnetic coupling and forming machine technology, applied in the direction of electric processing equipment, metal processing equipment, accessory devices, etc., can solve the problems of high installation accuracy, affecting processing accuracy, inconvenient maintenance, etc., achieve long service life, improve reliability, Easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below with reference to the accompanying drawings and examples. The principles and features of the present invention are described below in conjunction with the accompanying drawings. It should be noted that the accompanying drawings are only schematic diagrams provided for explaining the present invention, rather than real physical projection drawings; The embodiments and the features in the embodiments can be combined with each other. The examples given are only for explaining the present invention, not for limiting the scope of the present invention.

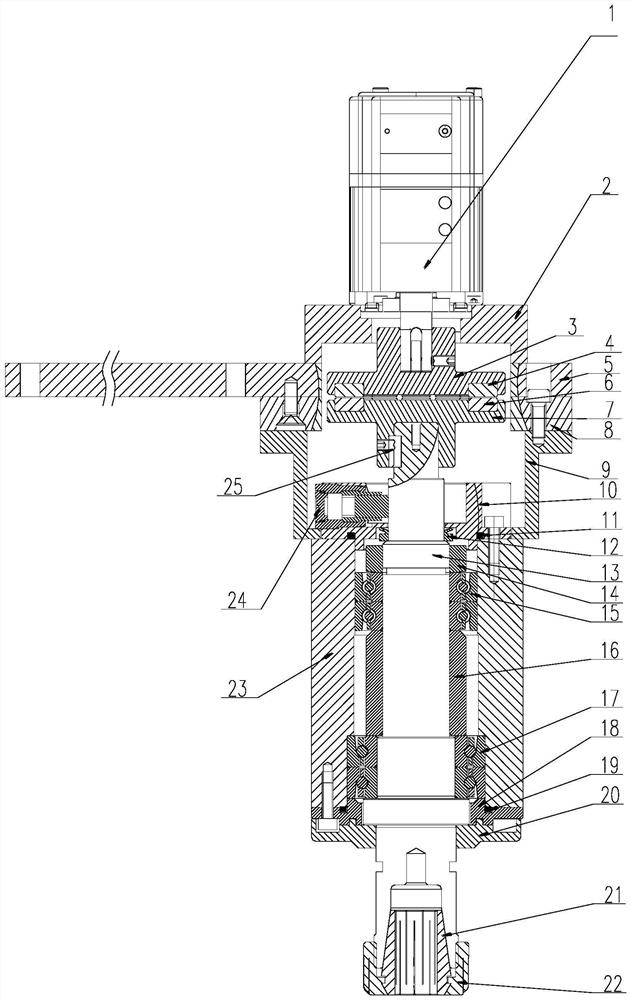

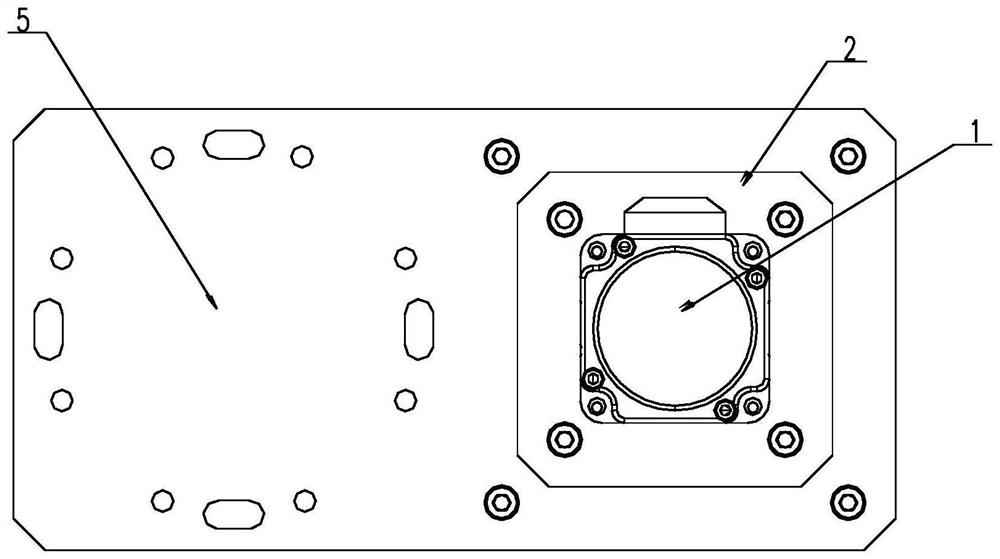

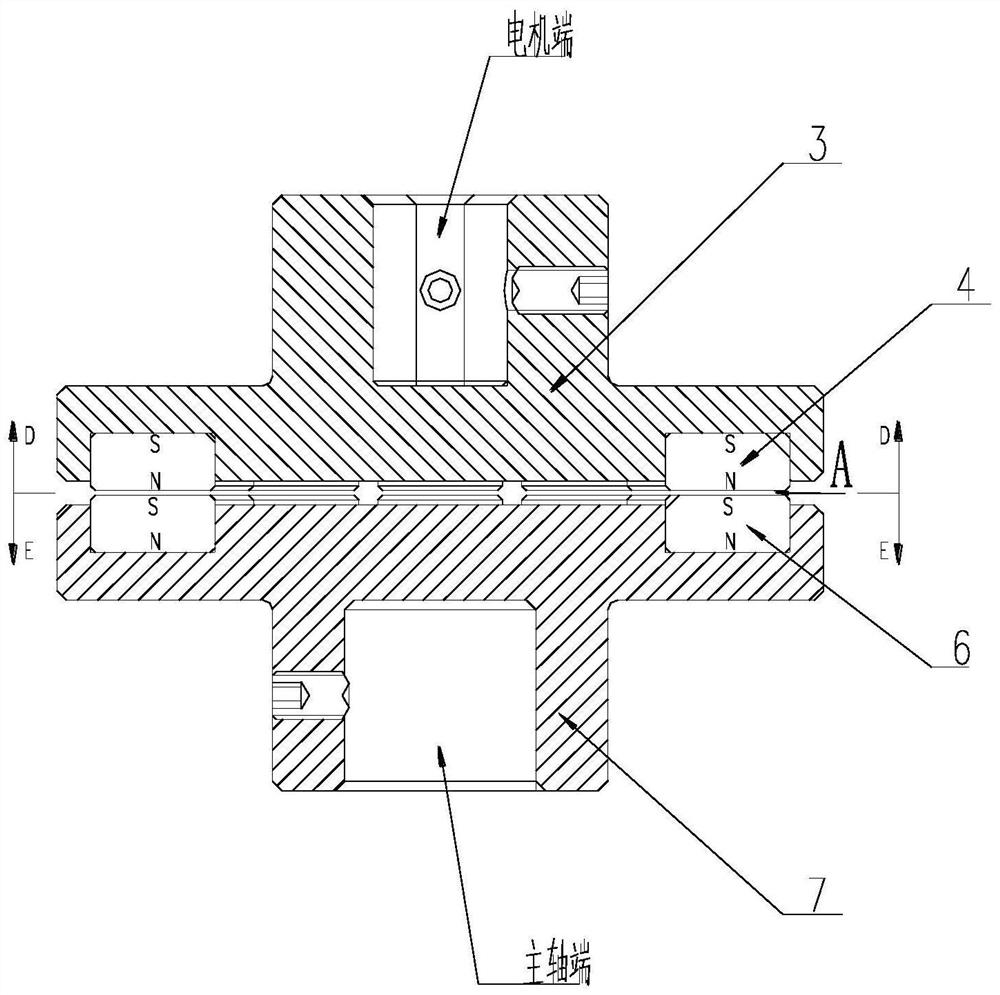

[0053] See eg Figure 1 to Figure 8 as shown, figure 1It is a schematic diagram of a cross-sectional structure assembly structure of a specific embodiment of a direct-connected magnetically coupled rotating shaft for an electric discharge forming machine provided by the present invention; figure 2 for figure 1 The top view structural schematic diagram of the specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com