Inverted T-shaped blind hole ceramic dielectric filter and special die thereof

A technology for ceramic dielectrics and filters, applied in molds, waveguide devices, electrical components, etc., can solve the problems of increasing the depth of blind holes, occupying surface area, increasing surface area, etc., to improve the dielectric constant, improve the Qf value, The effect of saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

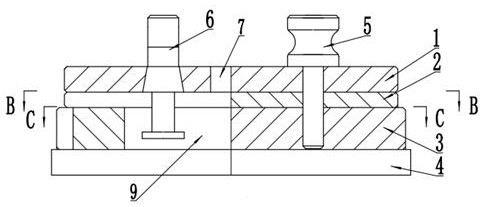

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0053] Specific implementation 1

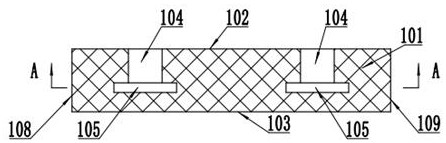

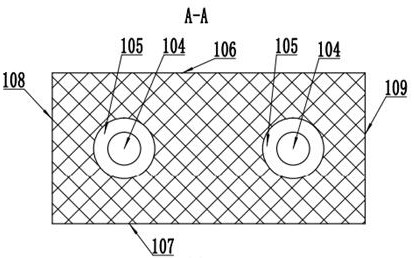

[0054] Such as figure 1 and 2 As shown, the inverted T-shaped blind hole ceramic dielectric filter of the present invention includes a hexahedral ceramic plate body 101, and the ceramic plate body 101 includes an upper surface 102, a lower surface 103, a front surface 106, a rear surface 107, a left surface 108 and a right On the surface 109, two upper holes 104 are arranged downwards on the upper surface 102 of the ceramic plate body 101, and lower holes 105 are respectively arranged below the two upper holes 104, and the diameter of the lower holes 105 is larger than the upper hole 104, further speaking, the diameter of the upper hole 104 is 3-4 mm, the diameter of the lower hole 105 is 6-9 mm, the upper hole 104 communicates with the lower hole 105, and the lower hole 105 communicates with the ceramic plate The lower s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com