Cleaning method for ultrafiltration system of garbage power plant

An ultrafiltration system, technology for power plants, applied in chemical instruments and methods, special treatment targets, water/sewage treatment, etc. Cleaning effect, improve water output, avoid frequent chemical cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

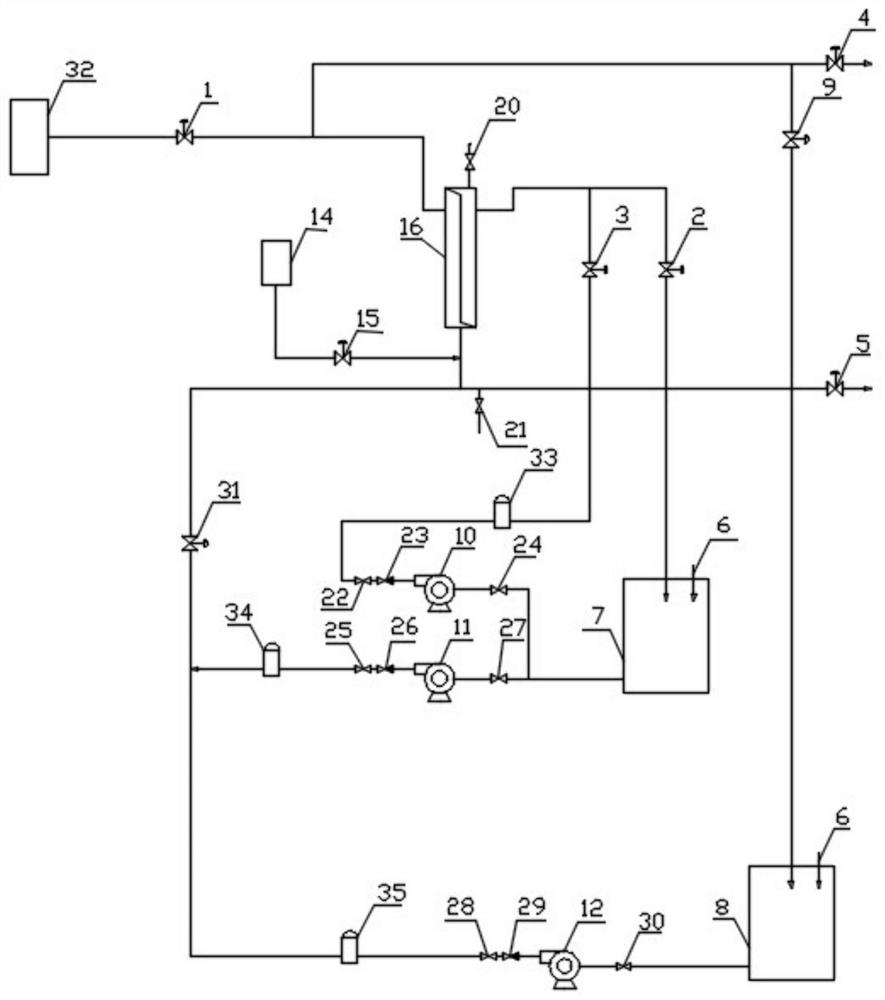

[0042] When the water flow rate of the ultrafiltration device drops ≥ 20% or the transmembrane pressure difference ≥ 0.10MPa, the ultrafiltration device of the waste-to-energy plant should be cleaned. The specific cleaning process is as follows:

[0043] (1) Compressed air purging

[0044] 1. The DCS of the ultrafiltration system is in the maintenance state, and all valves are switched to the stop (manual) position;

[0045] 2. After confirming that the pressure of the compressed air tank 14 is normal, open the compressed air purge pneumatic valve 15, purge the ultrafiltration membrane for 5 minutes, and then close the compressed air purge pneumatic valve;

[0046] (2) Backwash

[0047] 1. Inject 2 / 3 of the liquid level of reverse osmosis product water into the ultrafiltration water tank 7, add 70kg of citric acid, and add chemically pure hydrochloric acid to adjust the pH value of the liquid medicine in the ultrafiltration water tank 7 to 1-2;

[0048] 2. Open the ultrafil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com