Water-spot-resistant and whitening-resistant polyester resin as well as preparation method and application thereof

A polyester resin, anti-whitening technology, applied in polyester coatings, coatings, powder coatings, etc., can solve the problems of regional whitening, easy yellowing, and reduction to less than 10%

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

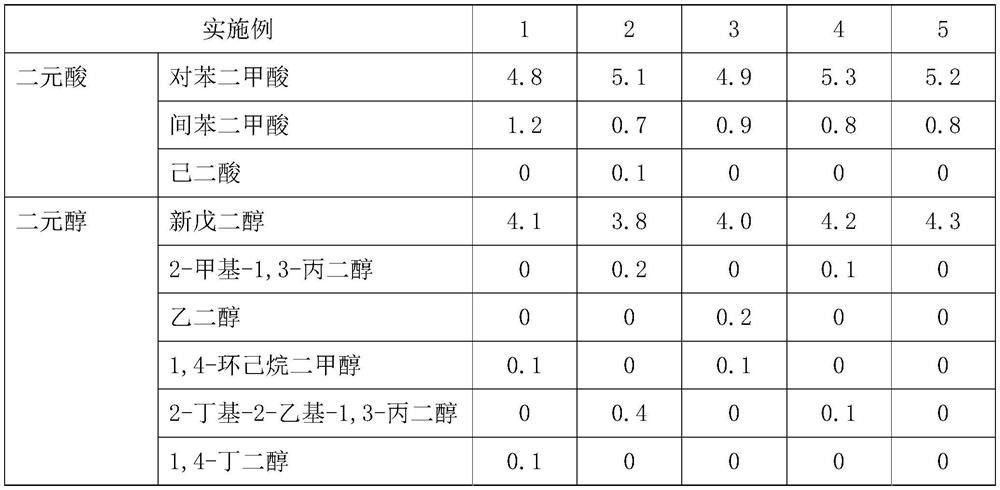

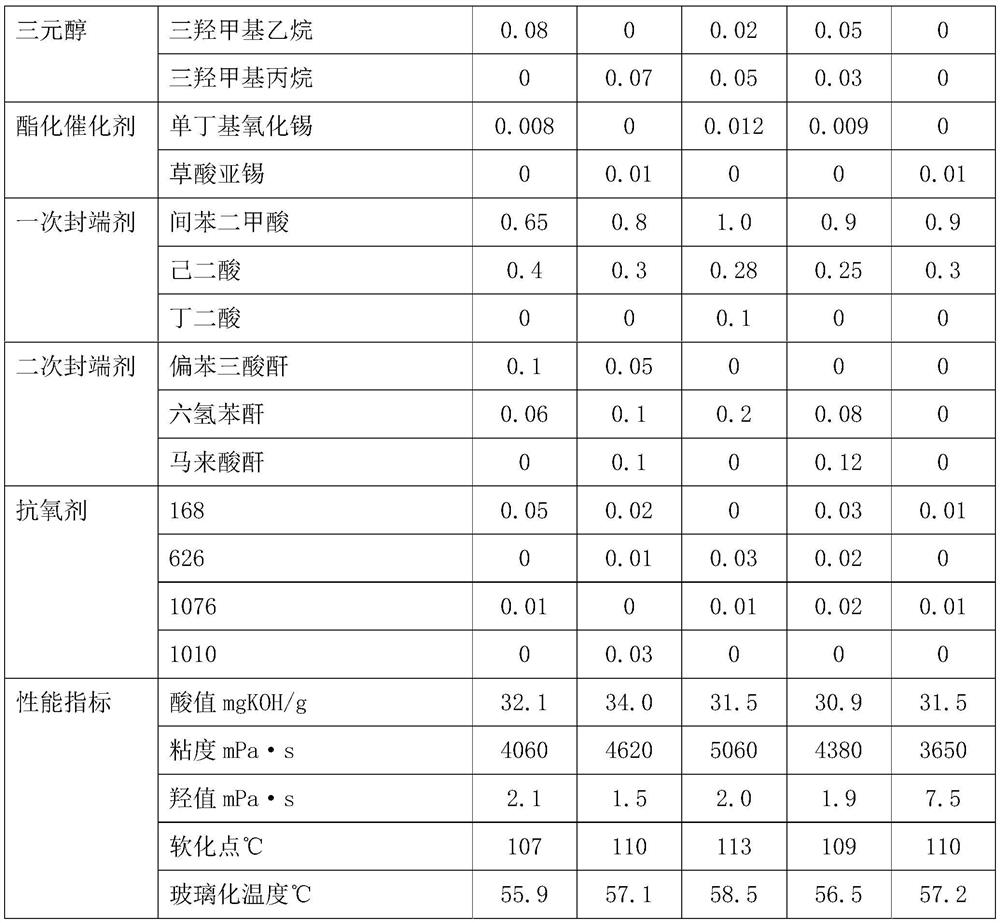

[0043] A water-spot and anti-whitening polyester resin, its raw material components and their quality are shown in Table 1.

[0044] The preparation method of the water spot-resistant and anti-whitening polyester resin is as follows: according to Table 1, put the formula amount of dihydric alcohol and trihydric alcohol into the reaction kettle, heat to 120°C to melt, start stirring, and then add the formula amount of dibasic acid , esterification catalyst, heat up to 240°C and maintain the reaction until the acid value is 8.9mgKOH / g; cool down to 228°C, put in a formula amount of end-capping agent, raise the temperature to 240°C, and maintain the acid value to 38.8mgKOH / g; Vacuumize for 2 hours at 0.1MPa and 232°C to obtain a carboxyl-terminated polymer with an acid value of 27.7mgKOH / g, a viscosity of 4150mPa·s, and a hydroxyl value of 8.9mgKOH / g; then cool down to 204°C and put in a secondary end-capping agent , after maintaining for 60min, vacuumize for 2h under the conditi...

Embodiment 2

[0050] A water-spot and anti-whitening polyester resin, its raw material components and their quality are shown in Table 1.

[0051] The preparation method of the water-spot-resistant and anti-whitening polyester resin is as follows: according to Table 1, put the formula amount of dihydric alcohol and trihydric alcohol into the reaction kettle, heat to 130°C to melt, start stirring, and then add dibasic acid, ester Catalyst, heat up to 242°C to maintain the reaction until the acid value is 10.1mgKOH / g; cool down to 224°C, put in a capping agent once, raise the temperature to 243°C, and maintain the acid value to 39.8mgKOH / g; at -0.1MPa, 231 Vacuum at ℃ for 3 hours to obtain a carboxyl-terminated polymer with an acid value of 28.5 mgKOH / g, a viscosity of 4550 mPa·s, and a hydroxyl value of 7.2 mgKOH / g; then lower the temperature to 210 °C and put in a secondary end-capping agent for 52 minutes , evacuated for 1.5h under the condition of -0.1MPa, and finally put in the antioxida...

Embodiment 3

[0057] A water-spot and anti-whitening polyester resin, its raw material components and their quality are shown in Table 1.

[0058] The preparation method of the water-spot-resistant and anti-whitening polyester resin is as follows: according to Table 1, diols and triols are put into a reaction kettle, heated to 140° C. to melt, and the stirring is started, and then a dibasic acid and an esterification catalyst are added. Raise the temperature to 244°C to maintain the reaction until the acid value is 11.3mgKOH / g; cool down to 222°C, put in a capping agent once, raise the temperature to 245°C, and maintain the acid value to 41.0mgKOH / g; at -0.1MPa, 234°C Vacuumize for 2 hours to obtain a carboxyl-terminated polymer with an acid value of 29.1 mgKOH / g, a viscosity of 5010 mPa·s, and a hydroxyl value of 6.1 mgKOH / g; then lower the temperature to 215°C and put in a secondary end-capping agent, and after maintaining for 44 minutes, - Vacuumize at 0.1MPa for 1.5h, and finally put in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com