Mg/Ni/In hydrogen storage material and preparation method thereof

A hydrogen storage material, mg2-xniinx technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of inconvenient transportation, long preparation period, limited commercial application, etc., to prolong the pulverization time and improve the cycle. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

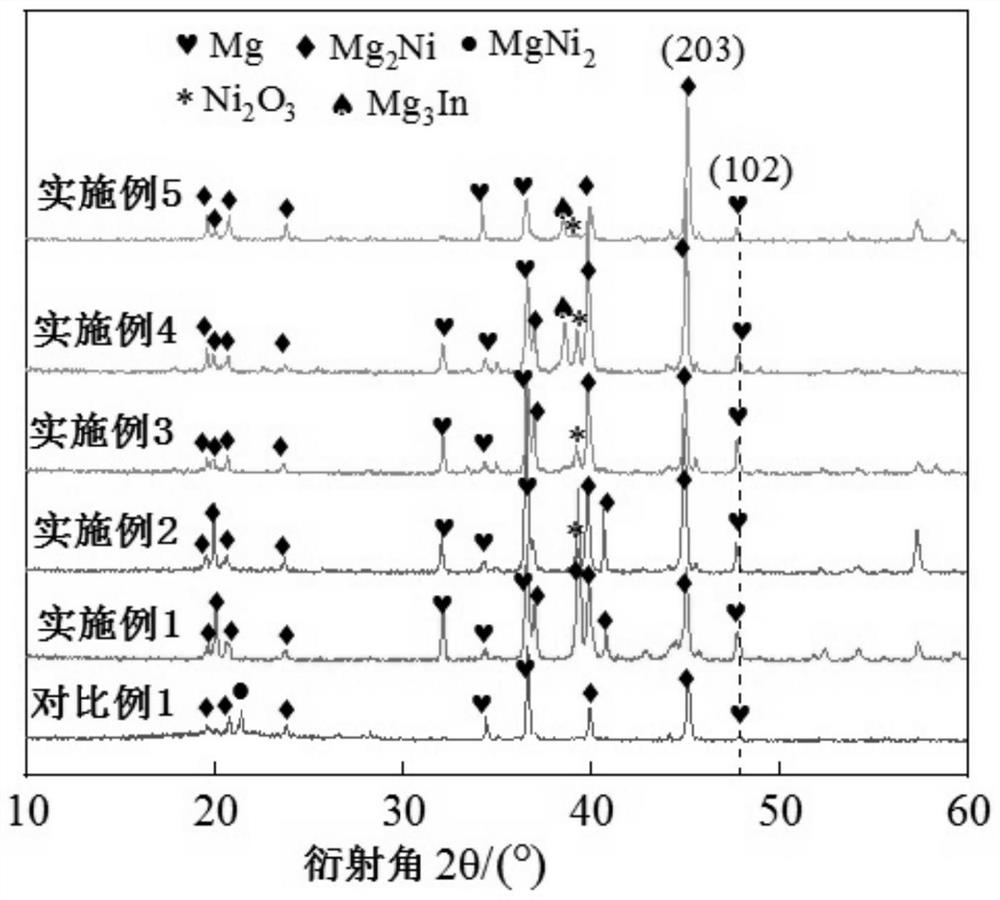

Embodiment 1

[0044] An embodiment of the present invention provides a hydrogen storage material, the chemical formula of the hydrogen storage material is Mg 1.95 NiIn 0.05 .

[0045] The preparation method of the above-mentioned hydrogen storage material comprises the following steps:

[0046] Step 1, taking Mg ingot, analytically pure Ni powder and analytically pure In powder according to the above-mentioned raw material ratio;

[0047] Step 2: Mix the Ni powder and In powder to obtain a mixed powder, then add absolute ethanol, ultrasonically disperse under the condition of 180w for 12 minutes, and then dry at 50°C for 2 hours at a low temperature to obtain a pretreated powder, wherein the The mass ratio of dehydrated alcohol and described mixed powder is 20:1;

[0048] Step 3, the pretreatment powder is evenly covered on the Mg ingot, and pressed for 30 minutes under a pressure of 25 MPa to obtain a magnesium-based material;

[0049] Step 4, under the condition of argon gas, place the ...

Embodiment 2

[0051] An embodiment of the present invention provides a hydrogen storage material, the chemical formula of the hydrogen storage material is Mg 1.9 NiIn 0.1 .

[0052] The preparation method of the above-mentioned hydrogen storage material comprises the following steps:

[0053] Step 1, taking Mg ingot, analytically pure Ni powder and analytically pure In powder according to the above-mentioned raw material ratio;

[0054] Step 2: Mix the Ni powder and In powder to obtain a mixed powder, then add absolute ethanol, ultrasonically disperse for 10 min at a power of 200w, and then dry at a low temperature of 45°C for 2.5 hours to obtain a pretreated powder, wherein the The mass ratio of said dehydrated alcohol and said mixed powder is 18:1;

[0055] Step 3, the pretreatment powder is evenly covered on the Mg ingot, and pressed for 35 minutes under a pressure of 23 MPa to obtain a magnesium-based material;

[0056] Step 4, under the condition of argon gas, place the magnesium-b...

Embodiment 3

[0058] An embodiment of the present invention provides a hydrogen storage material, the chemical formula of the hydrogen storage material is Mg 1.85 NiIn 0.15 .

[0059] The preparation method of the above-mentioned hydrogen storage material comprises the following steps:

[0060] Step 1, taking Mg ingot, analytically pure Ni powder and analytically pure In powder according to the above-mentioned raw material ratio;

[0061] Step 2: Mix the Ni powder and In powder to obtain a mixed powder, then add absolute ethanol, ultrasonically disperse for 13 minutes at a power of 190w, and then dry at a low temperature of 55°C for 1.5h to obtain a pretreated powder, wherein the The mass ratio of said dehydrated alcohol and said mixed powder is 22:1;

[0062] Step 3, the pretreatment powder is evenly covered on the Mg ingot, and pressed for 25 minutes under a pressure of 27 MPa to obtain a magnesium-based material;

[0063] Step 4, under the condition of argon gas, place the magnesium-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com