Wall protecting device for cast-in-situ bored pile and working method

A technology of bored cast-in-place piles and casings, which is applied in excavation, foundation structure engineering, construction, etc. It can solve problems such as insufficient mud wall protection effect, prolonged construction period, and environmental pollution, so as to improve construction efficiency and construction quality, and reduce engineering costs. Construction cost, effect of reducing engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

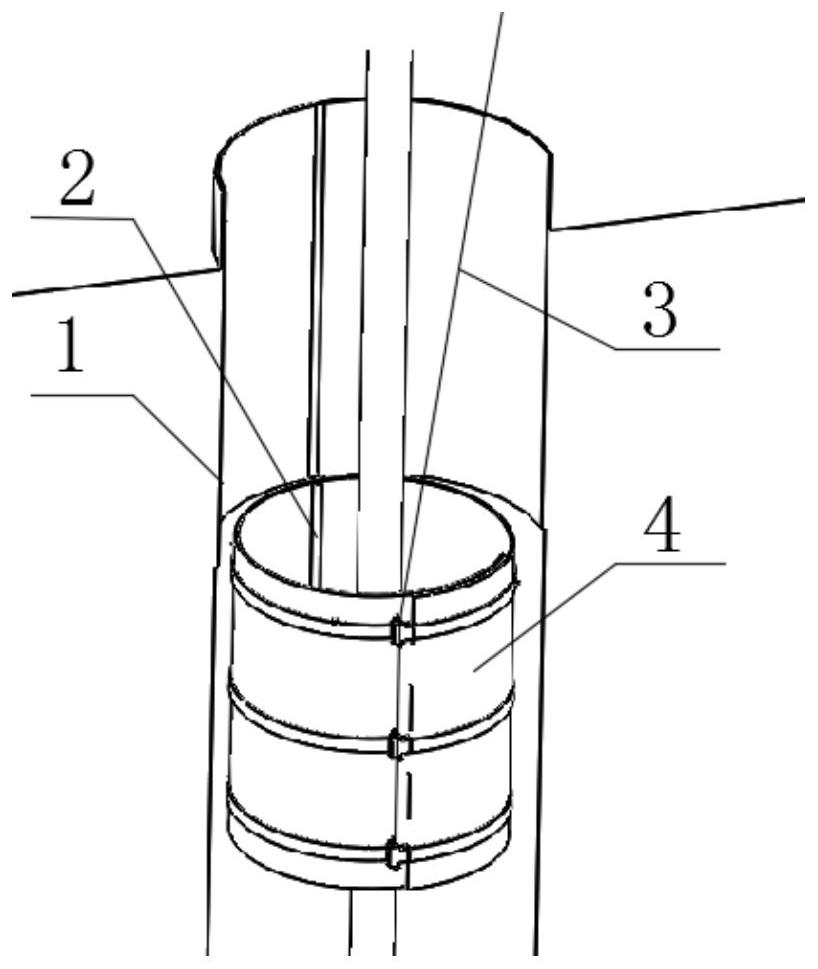

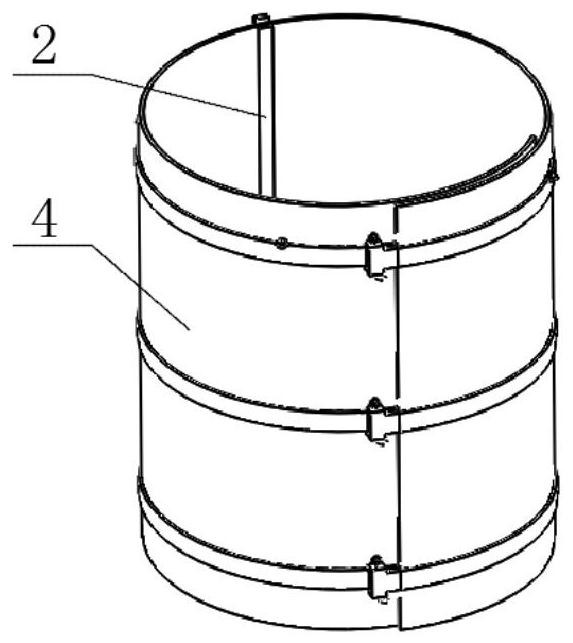

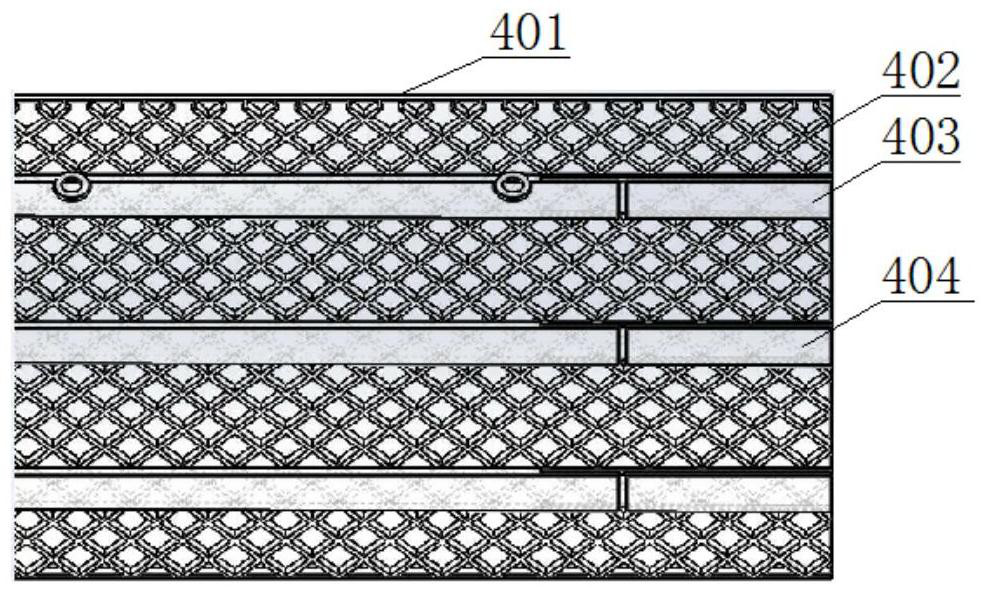

[0075] The bored pile hole is 30m deep, the pile hole diameter is 1.5m (the pile hole circumference is about 4.7m), and the geological conditions are the soil structure in the northern Anhui Plain. The depth of the steel casing is 3m, the ground is 1m higher, and the depth of the pre-embedded steel casing is 2m; the flat length of the second casing is 5.2m, and the height is 2.6m. The entire wall construction uses 10 sections of the second casing, and there is sediment at the bottom of the pile hole , leaving a height of 2m at the bottom without supporting the second casing.

[0076] During construction, the guide rail is first installed on the second casing, and the locking buckle is welded to the corresponding position of the elastic steel hoop; as the depth of the pile hole (drilling) increases, the second casing is supported while drilling. A section of the second casing is bent around the drill pipe on the pile foundation surface to form a cylinder with a diameter of 1.2m...

Embodiment 2

[0079] The bored pile hole is 40m deep, the pile hole diameter is 1.8m (the pile hole circumference is about 5.7m), and the geological conditions are the soil structure in the northern Anhui Plain. The depth of the steel casing is 3m, the ground is 1m higher, and the depth of the pre-embedded steel casing is 2m; the second casing has a flat length of 6.2m and a height of 3.0m. The entire wall construction uses 12 second casings, and there is sediment at the bottom of the pile hole , leaving a height of 2m at the bottom without supporting the second casing.

[0080]During construction, first install the guide rail on the second casing, and weld the locking buckle to the corresponding position of the elastic steel hoop; as the drilling depth increases, carry out the operation of supporting the second casing while drilling, and insert the first section and the second casing. The casing is bent around the drill pipe on the pile foundation surface to form a cylinder, the diameter o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com