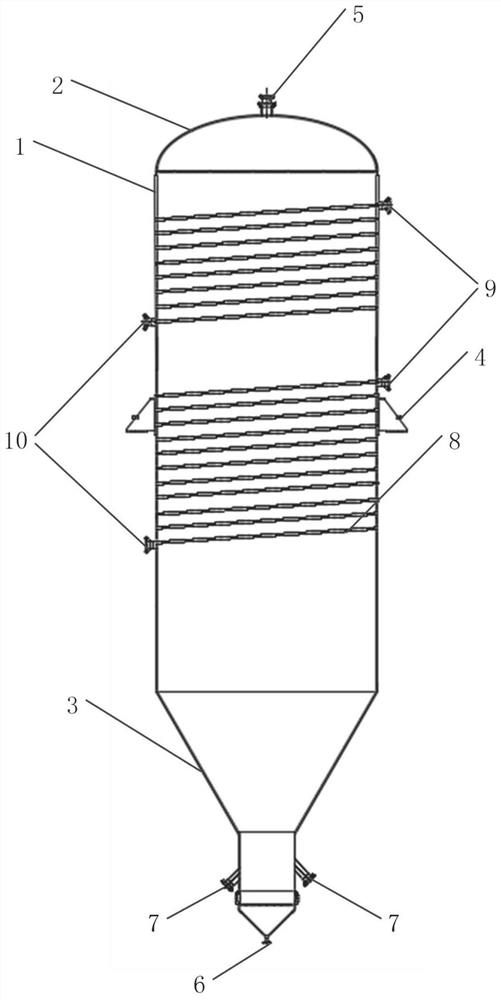

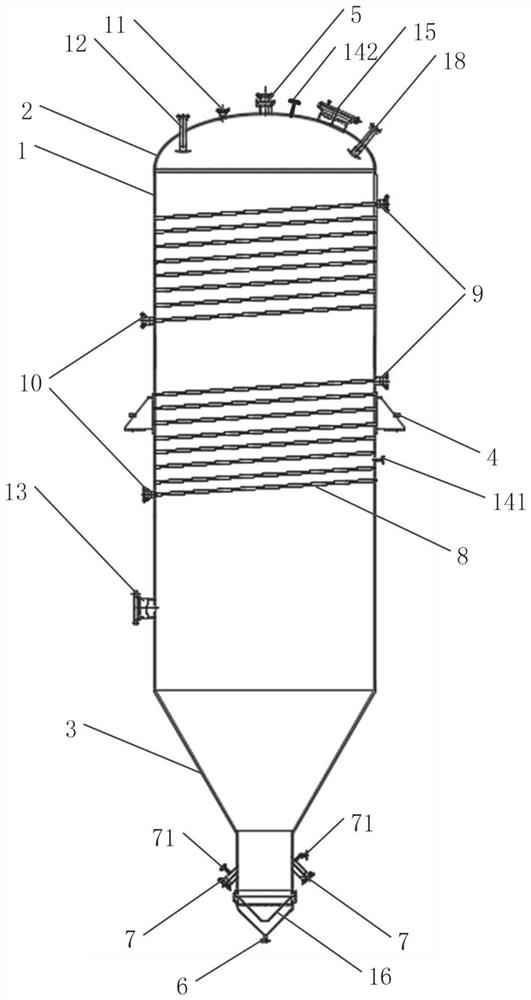

Solid particle heating tank

A solid particle, heating tank technology, applied in heat treatment, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of complex heating tank structure, inability to heat solid particles, insufficient fluidity of solid particles, etc. The effect of improving labor intensity, reducing the frequency of maintenance and/or replacement, and ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] In the present embodiment, the solid particle heating tank operates as follows during specific work:

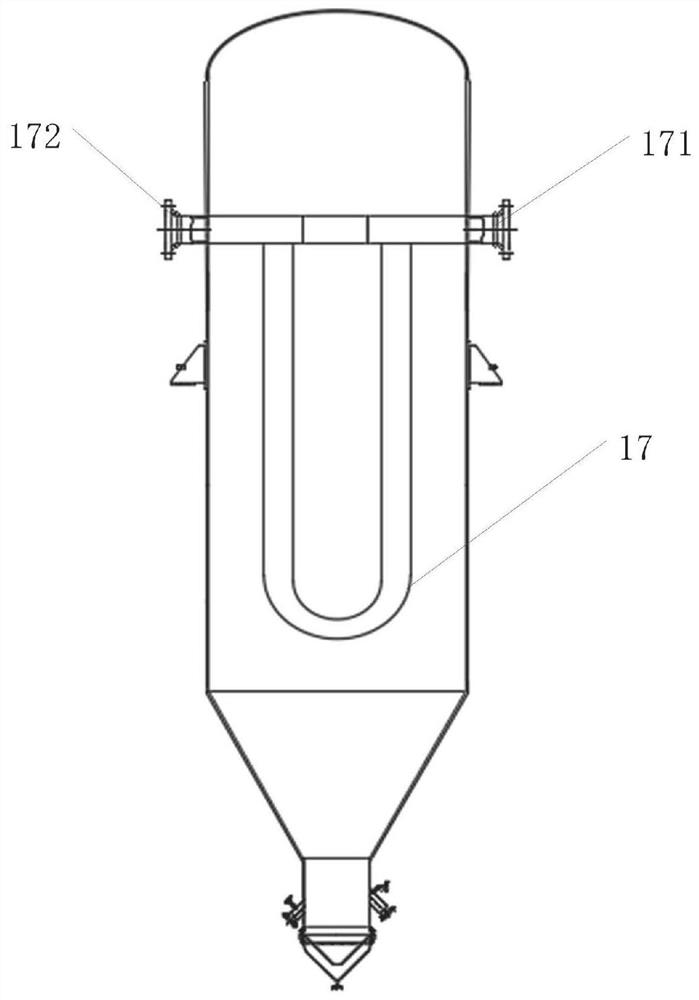

[0075] During specific use, take the synthesis of dimethyldichlorosilane monomer in organosilicon production as an example, silicon powder is passed into the heating tank from the solid particle feed port 5, nitrogen is passed into the nitrogen inlet 6, and the nitrogen flow rate is controlled as 800Nm 3 / h, nitrogen gas is evenly distributed inside the heating tank through the gas distributor 16, and silicon powder is in a flowing state in the heating tank at the same time. The coil 8 arranged on the outer wall of the tank body 1 is heated simultaneously with the U-shaped tube heat exchanger 17 inside the heating tank, so that the heating of the silicon powder is more uniform. The temperature rise rate of the silicon powder is 10°C / h, and the temperature of the heat transfer oil is maintained is 240°C. Open the first purge port 13 at regular intervals, and blow nitr...

Embodiment 2

[0077] In the present embodiment, the solid particle heating tank operates as follows during specific work:

[0078]During specific use, take the synthesis of dimethyldichlorosilane monomer in organosilicon production as an example, silicon powder is passed into the heating tank from the solid particle feed port 5, nitrogen is passed into the nitrogen inlet 6, and the nitrogen flow rate is controlled as 1000Nm 3 / h, nitrogen gas is evenly distributed inside the heating tank from bottom to top through the gas distributor 16, and silicon powder is in a flowing state in the heating tank at the same time. Using heat-conducting oil as the heating medium, and keeping the temperature of the heat-conducting oil at 260°C, the heat-conducting oil is passed into the coil tube 8 arranged on the outer wall of the tank body 1 and the U-shaped tube heat exchanger 17 inside the heating tank, and the silicon powder is heated by The inside and outside are heated at the same time, which makes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com