Dissimilar metal laser cladding welding device and method

A technology of dissimilar metals and laser cladding, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as performance and structure differences, difficulty in realizing metallurgical connections, and affecting the mechanical properties of joints, so as to promote the reaction and effectively It is beneficial to the mechanical properties of the weld and expands the effect of the connection structure of dissimilar metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings.

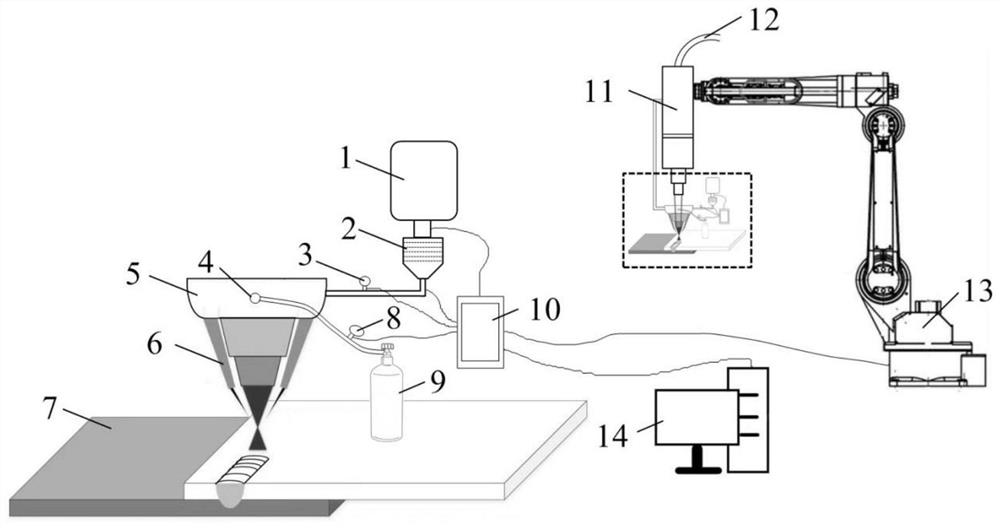

[0040] Such as figure 1 As shown, the dissimilar metal laser cladding welding device provided by the present invention includes: powder storage device 1; Connect; Powder feeding device 5 is used to convey metal powder to the test plate surface, the outlet of powder sieving device 2 is connected with the inlet of powder feeding device 5, and the quantity of powder feeding device 5 inlets is preferably four; Powder sieving device 2 and feeding The pipeline connected to the powder device 5 is provided with a solid flow meter 3; both sides of the powder feeding device 5 are provided with vent holes.

[0041] It also includes a gas source for providing a protective atmosphere in the powder feeding device 5; the gas source of this embodiment includes a gas cylinder 9, which is connected to the powder feeding device through the air inlet 4 on the powder feeding dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com